After kneading, mixing, the rubber material has been pressed to be hot rubber strip/sheet.

This rubber batch off cooler machine unit can make the hot rubber strip/sheet cooling and dip release agent.

Rubber batch off cooler machine unit work procedure is:

1. Take the hot rubber strip/sheet in, coat it with release agent.

2. Hang the rubber strip/sheet on festoons, cool and dry it by fans.

3. Stack rubber strip/sheet on pallet.

The rubber batch off cooler machine unit is floor stand type with the features of simple & rational structure, easy to operate.

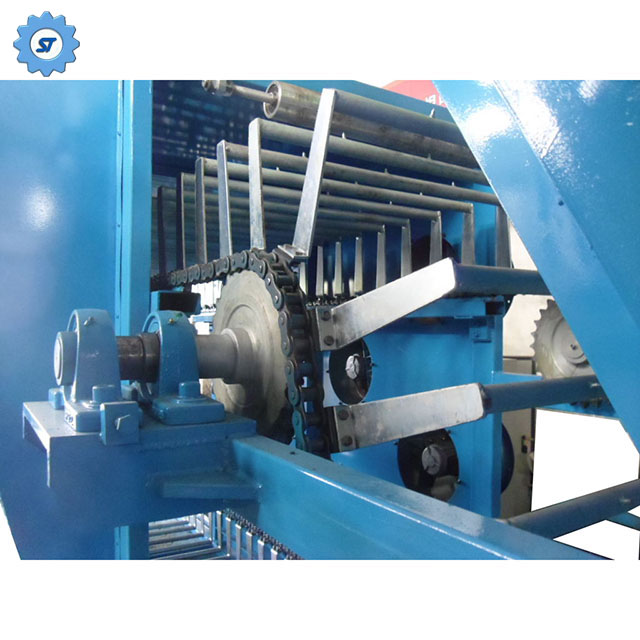

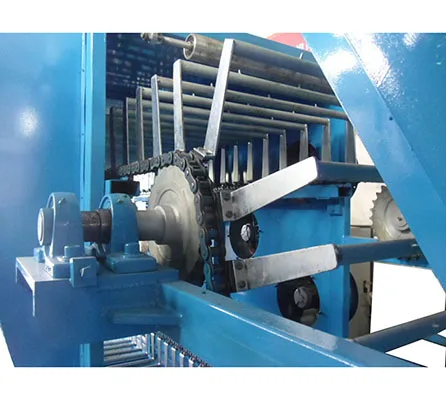

The rubber batch off cooler machine unit mainly consists of machine body and electrical control system.

The rubber batch off cooler body consists of inlet module, cooling device, lifting device, festoon module, down swing device, operating platform, and ladder etc. The electrical control system is in a control box, and set emergency control device on the machine.