Product Description

RIM series rubbers injection & pressure molding machine is suitable for injection and Molding all kinds of rubber. If change the machine barrel and screw, it can also be used to inject bakelite, plastic material. It is mostsuitable for high quality requirements, complex shape, thick wall and those products with embedded parts.

Features:

1,Injecting rubber after the mould being locked, high molding pressure in inner cavity of the mold/mould, high density construction of products, precise size with less scurf.

2, High speed open/close molds, high production efficiency, low blocking speed, protect mold.

3, Automatic in/out mold and ejector device, low labor strength.

4, Optional normal valve or proportional valve, matching-advanced oil way, reduce energy consumption.

5, the electric system adopts PLC programming control, which is easy to be operated.

Below is most often used model, we also accept customization according to customers’ special requirements.

|

Model

|

Screw Dia.(φmm)

|

Plasticizingcapacity(cm3/min)

|

Injectionpressure(MPa)

|

Piston Dia.

(φmm)

|

InjectionVolume

(cm3)

|

Moldlocking force

(KN)

|

PistonStroke(mm)

|

Hot platespacing

(mm)

|

Min. mouldthickness(mm)

|

Hot platensize(mm)

|

Installedpower(KW)

|

Dimension

(L×W×H)

(m)

|

TotalWeight(T)

|

|

RIM-100T

|

30

|

500

|

175

|

70

|

1000

|

1000

|

400

|

450

|

60

|

450×450

|

26

|

3×1.9×3

|

4

|

|

RIM-200T

|

40

|

800

|

173

|

80

|

2000

|

2000

|

500

|

570

|

80

|

550×550

|

30

|

3×2.3×4

|

6

|

|

RIM-300T

|

50

|

1000

|

180

|

95

|

3000

|

3000

|

600

|

750

|

160

|

700×600

|

40

|

3.4×2.3×4.4

|

10

|

|

RIM-400T

|

50

|

1000

|

195

|

95

|

4000

|

4000

|

600

|

Vulcanizing Injection Vulcanization Molding Machine Rubber Vulcanizer For Mold is widely been used to produce complex shape rubber products, rubber products with embedded metal. This rubber injection molding machine is auto feeding and auto measure feeding amount, auto injection, auto mold clamping, auto air exhaust, auto pressure compensate, auto molding open. So the production efficienty is very high and products quality is good.

Also horizontal rubber injection molding machine is raw material saving compared with common plate vulcanizing press, and the horizontal type machine is lower in height than vertical type, easy loading into container as a whole.

Our Rubber Injection Molding Machine Features:

1) The Silicon Rubber Injection Transfer Molding Vulcanizing Press Machine is full-automatic rubber injection oil pressure molding Machine.

2) The Silicon Rubber Injection Transfer Molding Vulcanizing Press Machine is full Scale Oil circuit System is applied in the rubber injection press machine;

3) Completely No Material Feeding Back Non-return Valve Design;

4) Full-direction Computerized Monitor& Control System;

5) The High-precision Optical Scale can control the injection volume,matching the Three-stage injection control;

6) Double-spiral Close-circuit Temperature Control System;

7) The Silicon Rubber Injection Transfer Molding Vulcanizing Press Machine is suitable for the multilateral,multiangular and complicated finished

products,especially the highly precise products such as sports,medical,automobile,and electronic equipment,etc.

Machine Making Procedure

1. Machine design, give detail drawings to the workshop for every machine parts processing, and treatment, and self checking by worker all the time.

2. QC team checking.

3. Then installation the machine.

4. Trial running the machine.

5. Packing.

6. Delivery

We always pay great effort on every detail in our machine production. From machine parts processing, electronics layout and machine installation, to export loading and delivery.

Machine Control cabinet. Our rubber injection molding machine adopts top level electronics, wire layout desing is very scientific.

So the machine electronics is very reliable even in the harsh working condition.

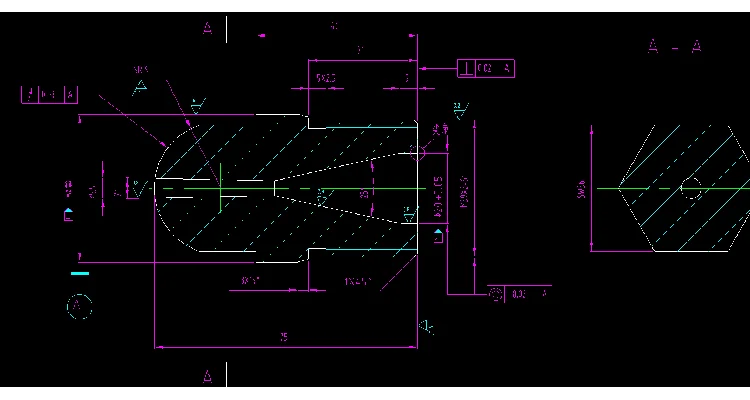

Piston Processing and Treatment

Piston adopts chilled hard cast iron, high precision machining and fine grinding treatment. Ensures the piston is super wear-resistant and durable in service life.

Heating Plate

Heating plate machining, drilling, grinding and heat treatment, ensures surface hardness and quality in use.

Casted Oil Cylinder

The oil cylinder is QT500 ductile iron casted. The quality is

assured.

Cylinder Seals

Seals we use imported international quality sealing ring and dust proof ring, which ensures the service life and sealing effect.

Screw Processing and Treatment

The screw of the machine adopts high quality alloy steel.

1). 38CrMOALA(JIS SACM645).

2). 9Cr18MoV

This steel has very good hardness, it's most suitable material for making injection screws.

We do all the machining work very carefully, as well as treatment.Advanced nitriding process

Corrosion&Abrasion resistance bimental spraying process

Nitrided Hardness: HV900-1000

Nitrided Depth:0.5-0.8mm

Alloy Hardness: HRC50-65

Alloy Depth: 0.8-2.0mm

Valves

Heating plate machining, drilling, grinding and heat treatment, ensures surface hardness and quality in use.

Injection Port design, this part should match with the sprue of the molds.

Below form are some commonly used models. Please tell us your work needs, we can give you a most suitable proposal with best price.

The machine are directly loaded into export container, and well fixed and protected.

Training on Machine Operation, Maintenance

Training customers‘ how to use the machine and how to make the production. And machine maintenance. And according to customers'

condition, we can help customers decide what configuration machine to use.