Product Description

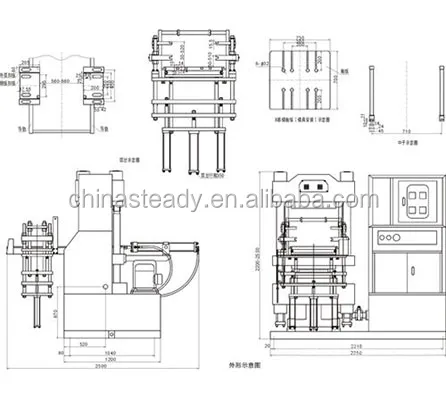

Vulcanizing machine is used for vulcanizing all kinds of rubber products. In our practical application, we usually add mold to produce all kinds of rubber and plastic products, like shoes tread, small tyre, packing ring, rubber oil seal and so on, and also some non-mould products like conveyor belt.

Structure:

The machine is mainly consists of oil hydraulic control system, piston, hot plate and electric relay or PLC control system.

Features:

1. The machine adopts electrical heating, steam heating or heat conducting oil heating according to customer requirements.

2. Heating Plate Material: used good quality steel-Q235-A.

3. Adopts automatic PLC touch screen control (option, if want PLC control, can choose electric relay manual control system), can realize the clamping, exhaust, temperature control, curing time, alarm, mold unloading function. Touch screen can display the plate temperature of each heating zone and timing.

4. Hydraulic cylinder made of ZG270-500 material, the plunger adopts hard alloy cast iron dense texture, after casting, finish grinding; sealing hydraulic cylinder adopts YX type sealing ring.

5. Hydraulic system: the hydraulic station using the well-known brands, can realize automatic mold open and close, exhaust and mold unloading.

Technical parameters:

Below are most common used models, we also customize machines as per customers special requirement.

Column type

|

Type

|

XLB-DQ400*400*2

|

XLB-DQ600*600*2

|

XLB-DQ750*850*2

|

XLB-DQ1000*1000*2

|

XLB-DQ1500*1500*2

|

XLB-DQ300*300*2

|

|

Total pressure(MN)

|

0.50

|

1.00

|

1.60

|

4.00

|

8.00

|

0.25

|

|

Plate size(mm)

|

400*400

|

600*600

|

750*850

|

1000*1000

|

1500*150

|

300*300

|

|

Plate clearance(mm)

|

125

|

125

|

125

|

125

|

125

|

125

|

|

Working layer

|

2

|

2

|

2(4)

|

2(4)

|

2(4)

|

2

|

|

Piston stroke(mm)

|

250

|

250

|

250(500)

|

250(500)

|

250(500)

|

250

|

|

Plate pressure(Mpa)

|

3.1

|

2.8

|

2.5

|

4.0

|

3.6

|

2.1

|

|

Motor power(kw)

|

2.2

|

3

|

3

|

5.5

|

5.5

|

2.2

|

|

Weight(kg)

|

1300

|

3500

|

6500

|

11000

|

22000

|

1050

|

Frame type

|

Type

|

XLB-D780*600

|

XLB-D800*1000

|

XLB-D900*1100

|

XLB-D1000*1200

|

XLB-D1350*1500

|

|

Total pressure (T)

|

160

|

250

|

300

|

500

|

1000

|

|

Plate size (mm)

|

780*600

|

800*1000

|

900*1100

|

1000*1200

|

1350*1500

|

|

Plate clearance (mm)

|

200

|

140

|

150

|

150

|

150

|

|

Layer number

|

2

|

4

|

4

|

4

|

6

|

|

Motor power (kw)

|

5.5

|

7.5

|

7.5

|

11

|

22

|

vulcanized rubber pressing machine is also called rubber press machine or rubber vulcanizer.

The machine's working principle is that it gives temperature and pressure to curing the rubber products.

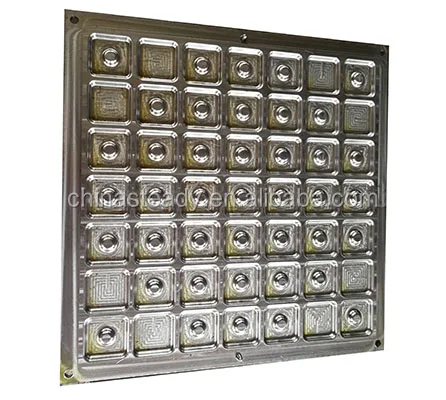

The make out rubber shape is depends on the shape of mold it using.

The procedure of Machine Making

1. Design and making drawing.2. Processing machine parts strictly as per drawings, every process must have checking and control by

worker themselves.

3. QC team checking quality and precision degree.

4. Installaton the rubber hot press machine.

5. Commissioning

6. Packing while book shipping.

7. Delivery, loading container.

Up mold and down mold consist a pair mold. When use the machine make the production. 1. Put rubber raw material into every cavity

of the down mold.

2. Press the mold close button on the machine.

3. The machine will close the mold, gives pressure and temperature.

4. When the set work time get out, the machine will open the mold automatically.

5. Workers get the finished rubber products out.

6. Do the next working cycle.

If there are different shape rubber products to make, just change the mold is ok, the machine is all purpose, universal use.

Some rubber products pictures just for reference. The machine can also make other shape when you mount other molds to it.

We always pay great effort in every detail of the production, from parts machining to installation and commissioing, to delivery, this ensures our machines are popular in international market.

Heating Plate Processing Technology

Heating plate machining, drilling, grinding and heat treatment, ensures surface hardness and quality in use.

Piston Machining

Piston adopts chilled hard cast iron, high precision machining and fine grinding treatment. Ensures the piston is super wear-resistant and durable in service life.

Heating Plate Installation

the heating plate has been processed with diagonal T-slot for customers easy mounting molds

Hydraulic Oil Cylinder, fine processing and good sealing

The oil cylinder is QT500 ductile iron casted. Piston adopts chiled hard alloy cast iron, seal adopts imported international quality sealing ring and dust proof ring, which ensures the service life and sealing effect.

Control Panel

There are temperature controller, current meter, control buttons and LCD display on the panel.

Valves

Our machine adopts international brand valves, ensure the work is accuracy,quick, stable, reliable and long service life.

Below is the commonly used rubber press machine models. If you need other size or pressure, please just feel free to contact us.

TECHNICAL SUPPORT

Training customers‘ how to use the machine and how to make the production. And machine maintenance. And according to customers'

condition, we can help customers decide what configuration machine to use

If the ordered quantity is not enough to a full container load, we'll use fumigation free wooden box with pallet base to ship the machine. Which is strong in long time sea transportation even with transshipment. If the rubber press machine ordered get to full container load, we'll directly use container comet to my factory to load them.