Rubber Kneader also called rubber kneading machine, rubber banbury mixer, is widely used in rubber and plastic industries.

It is applicable for plasticating, mixing and refining of rubber and plastics, and mixing of rubber and synthetic rubber.

The Rubber intensive banbury kneader feature is as below:

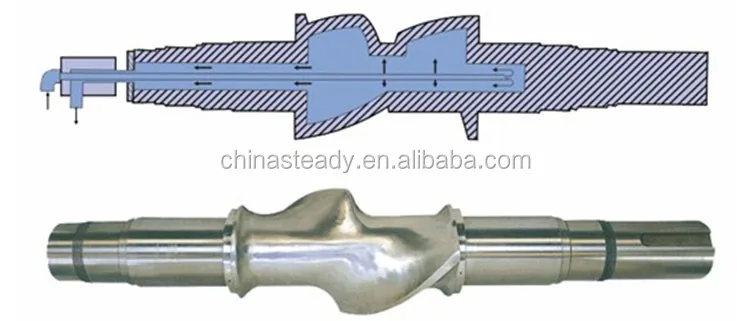

1. The Rubber intensive banbury kneader is an internal mixer with intermeshing rotors. The wings and the working surfaces of the rolls, the internal surfaces of the mixing chamber, and the working surfaces of the pressing ram device and the discharge device are all put on with wearable hard alloy by built-up welding method, which are durable and corrosion proof and have a longer life of service.

2. The shape of the rotors is cylindrical. As it has big wings with large cooling area, it can improve the quality of the mixing rubber and thus increase the productive efficiency. It may shorten two mixing periods into one.

3. With completely sealed condition, materials are mixed or plasticated under certain pressure, controllable temperature, which makes high production efficiency and obtains excellent stable quality.

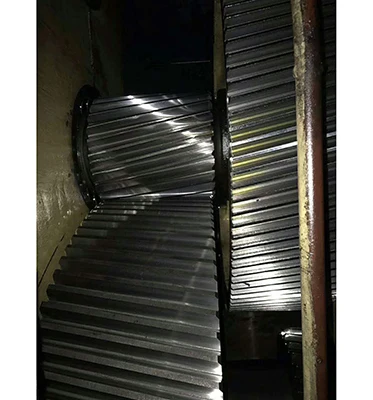

4. Spiral angle and over lapping length of the blades of the rotors are of reasonable design and make the materials to be dispersed uniformly.

5. Surface where is contracted with the machine are all plated with hard chromium and polished, which is corrosion-resistant and wear-resistant.

6. Jacket construction is adopted in parts that surfaces contact with materials to achieve excellent water-cooling or steam heating effect and fit in with the needs of plastics and rubber processing technology.

7. Feeding from back door on the frame (or separate top door) is convenient for continuous process operation in production line. The mixing chamber is able to turn forward by 140 around the front rotors to discharge and is easy for changing pigments and cleaning the chamber.

8. Programmable logic controller (PLC) is adopted in the electric-control system, which has reliable control function and alarm function, and interlock safety-protection function and it is provided with serial interface of net.

9. The motor wire of Qingdao Steady Machinery's rubber kneading machine is made of COPPER, the motor adopted is China famous brand. It's very durable and can longtime continuous running in scurviness condition (the working environment full of dust, as you can see from the above picture).

1) Simple structure,easy in installation and maintenance.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Rubber intensive banbury kneader is with hollow jacket structure which ensures good cooling effect.

4) Rubber intensive banbury kneader can be used to mixing various rubber and plastics material, including pigmen etc.

5) Our rubber intensive banbury kneader's rotors have smooth and rough two type for choice.

6) CE, GOST certificate for rubber kneading machine is available.

|

Model |

X(S)N-1×12~58 |

X(S)N-3×32(6~60) |

X(S)N-10×32 |

X(S)N-20×30 |

X(S)N-35×30 |

X(S)N-55×30 |

X(S)N-75×30 |

X(S)N-110×30 |

X(S)N-150×30 |

X(S)N-200×30 |

X(S)N-300×30 |

|

Total volume of kneading chamber(L) |

3 |

8 |

25 |

45 |

75 |

125 |

180 |

250 |

325 |

440 |

700 |

|

Working volume of mixing chamber (L) |

1 |

3 |

10 |

20 |

35 |

55 |

75 |

110 |

150 |

200 |

300 |

|

Driving motor power(KW) |

4 |

5.5 |

15 |

30 |

55 |

75 |

110 |

185 |

220 |

280 |

280/400 |

|

Overturn motor power(KW) |

manual |

0.55 |

1.1 |

1.5 |

2.2 |

3.0 |

4.0 |

5.5 |

5.5 |

7.5 |

7.5 |

|

Overturn angle(°) |

≤140 |

135 |

140 |

140 |

140 |

140 |

140 |

140 |

140 |

140 |

140 |

|

Rotation speed of rotor(front/back)r/min |

12~58 |

6-60 32/24.5 |

32/23.5 |

30/25 |

30/24.5 |

30/24.5 |

30/24.5 |

30/24.5 |

30/24.5 |

30/24.5 |

30/24.5 |

|

Pressure of compressed air(Mpa) |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

Flow rate of compressed air(m³/min) |

≥0.3 |

≥0.3 |

≥0.5 |

≥0.7 |

≥0.9 |

≥1.0 |

≥1.0 |

≥1.5 |

≥2.0 |

≥2.0 |

≥2.0 |

|

Pressure of cooing water(Mpa) |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

0.3-0.4 |

0.3-0.4 |

0.3-0.4 |

0.3-0.4 |

0.3-0.4 |

0.3-0.4 |

0.3-0.4 |

|

Pressure of heated steam(Mpa) |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

0.5-0.8 |

|

Overall dimension(L*W*H)(mm) |

1400*760*1914 |

1660*960*1750 |

2580*1300*2280 |

2630*1520*2550 |

3200*1900*2495 |

3360*1950*3050 |

3760*2143*3135 |

4075*2712*3580 |

4200*3300*4000 |

4520*3400*4215 |

5070*3500*4600 |

|

Weight(KG) |

800 |

2000 |

3300 |

4500 |

6500 |

7800 |

10500 |

14500 |

19500 |

22500 |

27500 |

Name: Control System

Brand: ABB or Siemens, Mirle

Original: Switzerland, Germany, Taiwan

Our kneader machine adopts international famous brand control system. The work is stable and accurate, reliable, trouble free.

Name: Electronics

Brand: STEADY

Original: China

Adopts international famous brand electronics, the work is reliable. Inside control box all electronics and wires are well designed, rational arrayed. So the wire connection and operation is easy and maintenance is easy.

Name: Rotors

Brand: STEADY

Original: China

The sealing ring is best copper ring, ensure there's no rubber leakage in long time working . The rotors adopts 42CrMo material, and surface chrome plated(thickness +0.1-0.15mm), the the surface is very hard HRC52. The rotors are hollow structure, for good water cooling effect.

Name: Mixing Chamber

Brand: Steady

Original: China

The mixing chamber adopts cast steel, inside is chrome plated and polish to mirror effect. And the sides are drilled for good water cooling effect.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

Size

|

3200 (L) * 1900 (W) * 2945 (D)

|

|

Weight

|

6.5 T

|

|

Packaging Details

|

The normal package is wooden box for smaller model . The wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Packaging

|

|

|

Size

|

3760 (L) * 2143 (W) * 3135 (H)mm

|

|

Weight

|

10 T

|

|

Packaging Details

|

For big model kneader or small model exported with other machines together. We will load the machine into container directly and well protected and fixed in the container.

|