A waste tyre cutting machine is a specialized piece of equipment designed to process and recycle used or end-of-life tires. These machines play a crucial role in the tire recycling industry by transforming large, bulky tires into smaller, manageable pieces, which can then be further processed into various recycled materials. Here's an overview of how these machines typically work and their significance:

### How it Works:

1. **Feeding System**: The first step involves loading the whole tires onto the machine. This can be done manually or through an automated feeding system that aligns the tire properly for cutting.

2. **Cutting Mechanism**: The core component of a tyre cutting machine is its cutting mechanism. This can vary but often includes circular saws, hydraulic shears, or even high-speed rotating blades. These mechanisms cut the tires into smaller sections, either radially (across the tread) or longitudinally (along the circumference), depending on the desired output and the machine's design.

3. **Size Adjustment**: Most machines allow for adjustments in cutting size, enabling the production of tire chips, shreds, or slices of varying thicknesses according to the recycling process they will undergo next.

4. **Safety Features**: Given the high-powered cutting tools involved, safety features like emergency stop buttons, protective guarding, and proper debris management systems are integral to ensure operator safety.

5. **Output Handling**: After cutting, the tire pieces are usually conveyed or dropped into collection bins or onto conveyor belts for further processing, such as granulation or shredding, which converts them into crumb rubber.

### Significance:

1. **Space Saving**: By reducing the volume of tires, these machines significantly save storage and transportation space, making the handling of waste tires more efficient.

2. **Environmental Benefits**: Recycling tires through cutting reduces the environmental impact of tire disposal, which otherwise can lead to fires, breeding grounds for mosquitoes, and pollution from leached chemicals.

3. **Resource Recovery**: Cut tire pieces can be transformed into a range of products, including rubberized asphalt, sports surfaces, playground mulch, and even new tires, promoting a circular economy.

4. **Energy Efficiency**: Recycling tires uses less energy compared to producing virgin rubber, contributing to energy conservation.

Overall, waste tyre cutting machines are a vital part of the tire recycling chain, facilitating the conversion of waste into valuable resources while addressing environmental challenges associated with tire disposal.

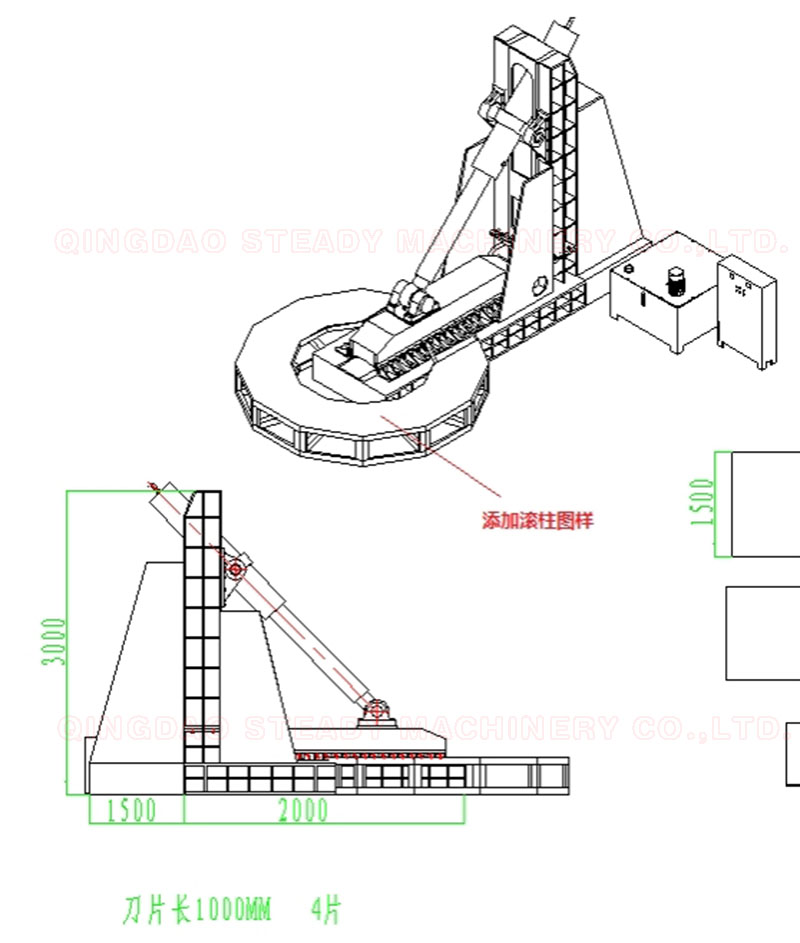

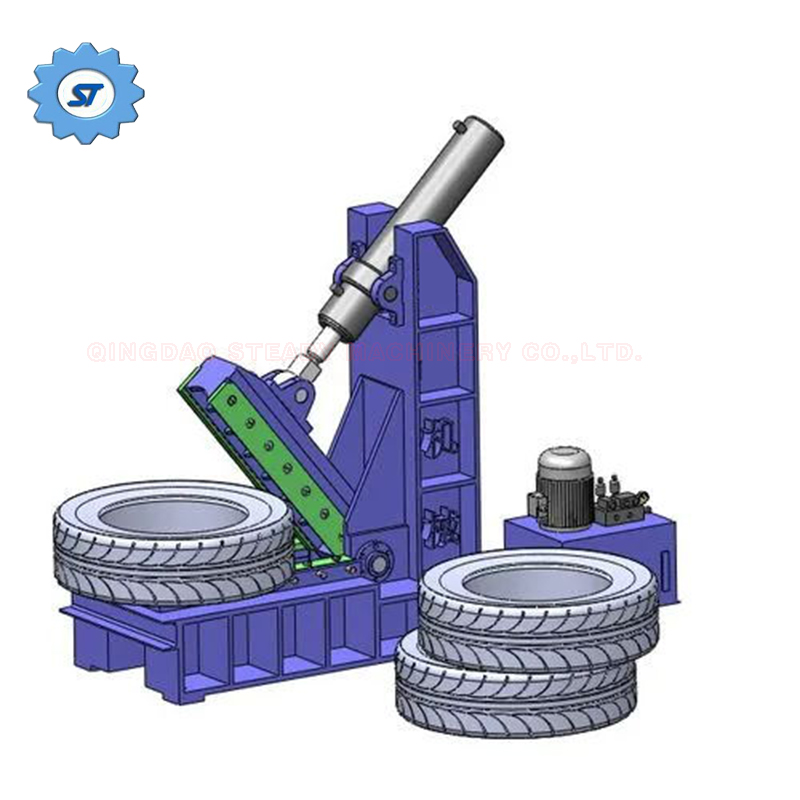

Sketch drawing for reference;

Common Models, if you have any special technical requirements, please just contact us.

Technical parameter:

Model | TC-2500 | TC-3800 |

Specification of raw material | 1400-2500mm tires | 2500-3800mm tires |

Specification of finished material | 200-400mm tire blocks | 200-400mm tire blocks |

Production Capacity | 10-15 tires per hour | 10-15 tires per hour |

Cutting force | 200T | 300T |

Max. Tyre diameter | ≤2500mm | ≤3800mm |

Knife material | High strength Alloy steel | High strength Alloy steel |

Knife quantity | 2 pieces | 2 pieces |

Control way | Automaticsystem | Automaticsystem |

Feeding way | Driving handling | Driving handling |

Main motor (kw) | 5.5 kw | 15 kw |

weight | About 8200kg | About 19000kg |

Detail Images of Rubber Tyre Cutting Machine:

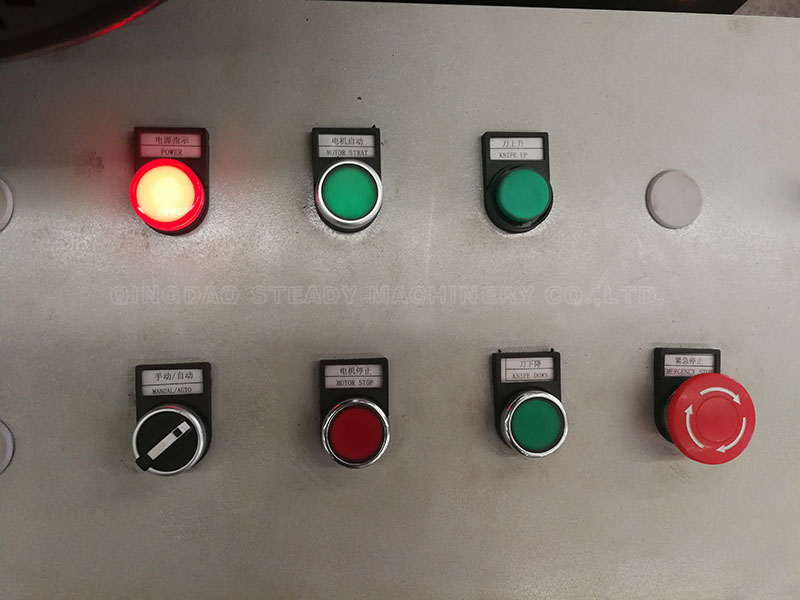

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put a few for your reference.

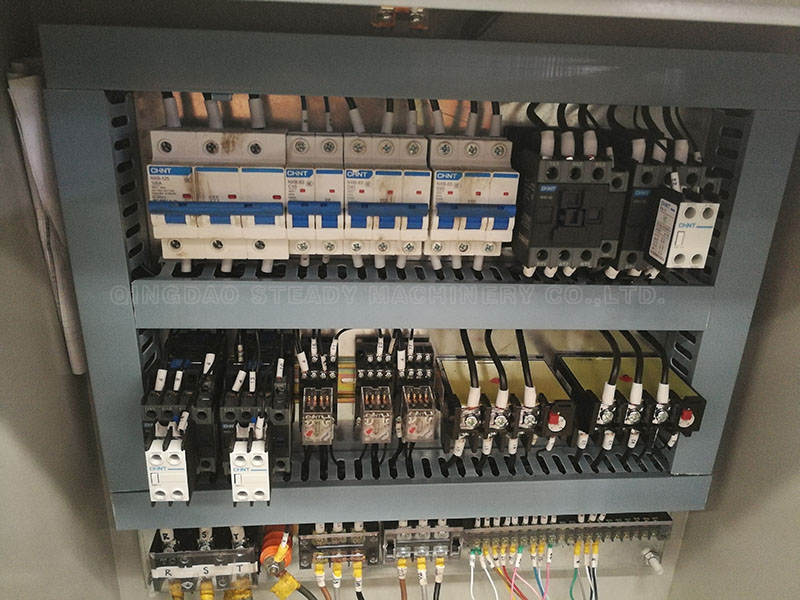

Control Box

Normally it's CHNT brand. If customers want other band, just tell us.

Cutters/kinves:

The alloy steel material cutting blade used for cutting waste tires needs to have high hardness and long service life characteristics. This type of cutter usually uses high-quality alloy steel as the substrate, and some cutting edges are welded with high hardness wear-resistant alloy welding rods to enhance their wear resistance and impact resistance. This can ensure that the cutter maintains good cutting efficiency and extends its service life when cutting hard and wear-resistant materials such as waste tires.

We use Cr12MoV alloy tool steel, which contains elements such as molybdenum and vanadium, improving the material's wear resistance and toughness.

Greatly enhances the durability and cutting performance of the blade.

It can ensure that the waste tire cutter maintains high hardness while also having good resistance to wear and thermal cracking, thereby ensuring that it can maintain good cutting performance and a longer service life in long-term, high-strength working environments.

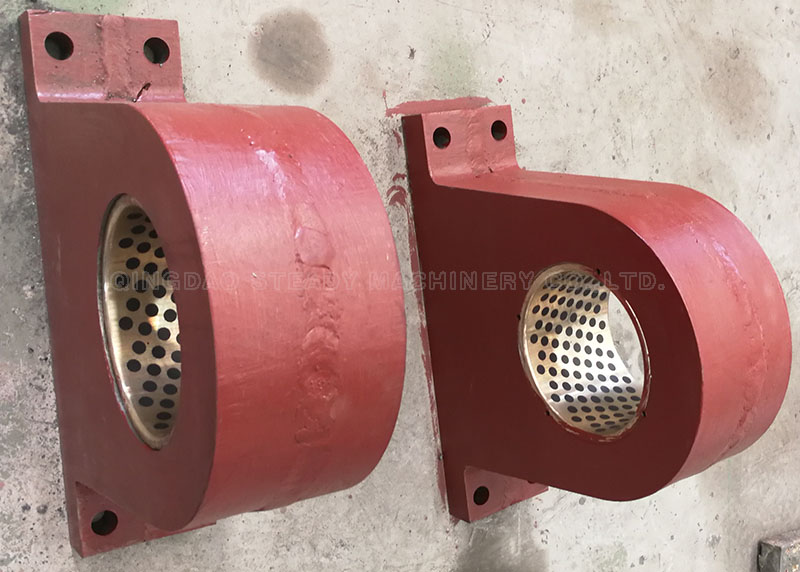

Wear resistant material adopted in shaft seat

Machine Installation

Loding Container Export

Just contact us

Comments: