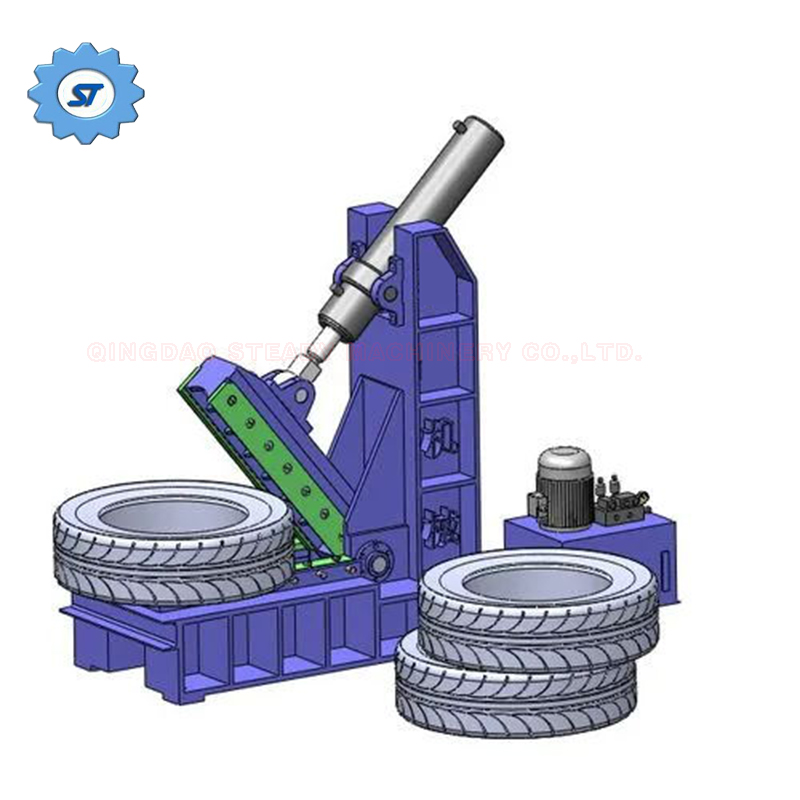

A waste tyre steel wire extractor machine, often work with tyre cutting machine. It is a critical component in the tire recycling process. Its primary function is to extract the steel wires from the bead area of waste tires,

which is the reinforced portion where the tire meets the wheel rim.

The process is essential because it separates the valuable steel wires from the rubber, allowing both materials to be recycled effectively. Here's an overview of how these machines operate and their importance:

### Operation Process:

1. **Loading**: Tires are initially loaded into the machine, either manually or via an automated feed system. They are positioned so that the bead area, where the steel wire is embedded, is aligned with the extractor mechanism.

2. **Cutting/Grabbing**: The machine employs powerful hydraulics or mechanical force to cut through the rubber and grab hold of the steel wires. Specialized cutting tools or strong gripping jaws are used to penetrate the

tough rubber compound and access the wires.

3. **Extracting**: Once the steel wires are securely gripped, the machine pulls them out of the tire, separating the wires completely from the rubber body. This action may involve a combination of pulling and rotating movements to

free the wires without damaging them.

4. **Discharge**: The extracted steel wires are then discharged from the machine, usually into a collection bin or conveyor for further sorting and recycling. The rubber part, now free of steel, moves on to the next stage of processing.

### Importance:

1. **Material Separation**: Efficient separation of steel wires is crucial for effective recycling. Steel can be melted down and reused in various industries, while clean rubber can be processed into crumb rubber or other products.

2. **Economic Value**: Steel wires have significant economic value and contribute to the profitability of tire recycling operations. Proper extraction ensures maximum recovery of this reusable resource.

3. **Environmental Impact**: Removing steel wires prevents contamination of rubber recycling streams, ensuring higher quality recycled products and reducing environmental pollution from mixed waste.

4. **Safety**: Handling large amounts of scrap tires can be hazardous. Automated steel wire extractors minimize manual handling, thereby improving workplace safety.

In summary, a waste tyre steel wire extractor machine is a fundamental piece of equipment in tire recycling plants, playing a vital role in efficient material separation, enhancing the overall sustainability and profitability of the

recycling process.

Common Models, if you have any special technical requirements, please just contact us.

TYRE DIAMETER | ≤1200mm |

PRODUCTION CAPACITY | 20-40 tires /hour |

EXTRACTION FORCE | 13T |

MOTOR POWER | 15KW |

MACHINE SIZE | 4200*900*1700(mm) |

MACHINE WEIGHT | 1690kg |

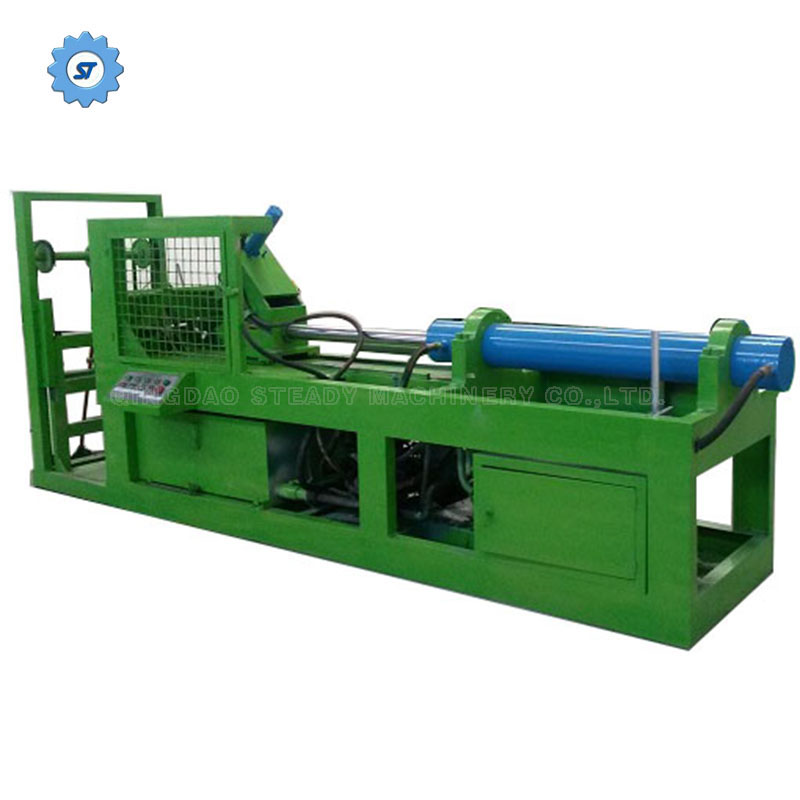

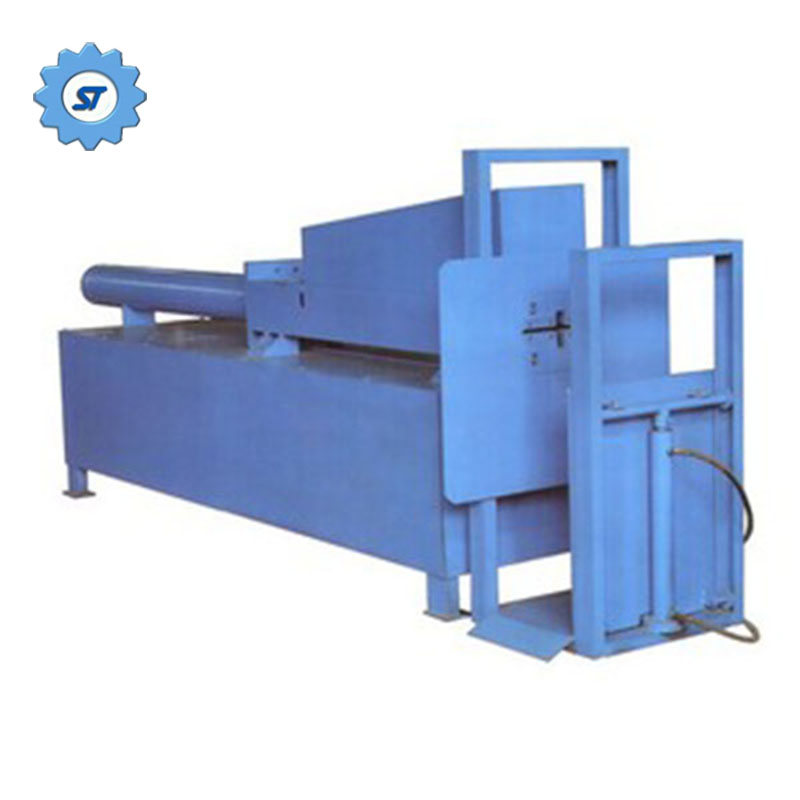

Images of waste tyre steel wire extractor machine and Other related machines:

waste tyre debeader( ring cutter), Strip cutter( cutting tyre into strips), Block cutte( cutting strips into small blocks)

and mouth steel wire separator.

Whole tyre cutter, it can cut whole tyre directly when the tyre size is not too big.

Just contact us

Comments: