A rubber cracker, also known as a rubber cracking mill or rubber crusher, is a machine used in the rubber industry to break down rubber scrap or waste into smaller pieces. It is a crucial component in the process of rubber recycling and is commonly used in tire recycling plants.

The primary function of a rubber cracker is to crush and reduce the size of rubber waste, such as used tires, rubber sheets, or rubber products, into smaller particles or granules. This process prepares the rubber material for

further processing, such as grinding, refining, or mixing. The machine typically consists of a pair of counter-rotating rolls with specially designed teeth or blades on their surfaces that crush and shear the rubber as it passes through the cracker.

Rubber crackers are typically designed to handle large volumes of rubber waste and can process various types of rubber materials. The resulting crushed rubber can be further processed or reused in various applications, such as the production of new rubber products, as fuel in industrial processes, or as a component in construction materials.

Proper maintenance and regular inspections of the rubber cracker are essential to ensure safe and efficient operation. Operators should follow safety guidelines and wear appropriate protective equipment when operating the machine. Regular cleaning and lubrication of the machine's components are also necessary to maintain optimal performance and extend its lifespan.

Common Models, if you have any special technical requirements, please just contact us.

Models | XKP-400 | XKP-450 | XKP-560 |

Working diameter of front roll(mm) | Φ400 |

Φ450 |

560 |

Working diameter of back roll(mm) | 400(fluted roll) | 450(fluted roll) | 560(fluted roll) |

Working length of roll(mm) | 600 | 650 | 800 |

Linear speed of front roll(m/min) | 18.6 | 24.5 | 25.6 |

Speed ratio of front and back rolls | 1:1.38 | 1:1.38 | 1:1.30 |

Max. roll distance(mm) | 8 | 8 | 15 |

Motor power(KW) | 45 | 55 | 75 |

Producing capacity (kg/h) | 200-300 | 600-800 | 1500 |

Overall dimension(L×W×H)(mm) | 3850×1800×1550 | 4650x2000x1550 | 4750x2300x2000 |

Weight(kg) | 7500 | 11000 | 18500 |

Detail Images of Rubber Open Mixer:

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put a few for your reference.

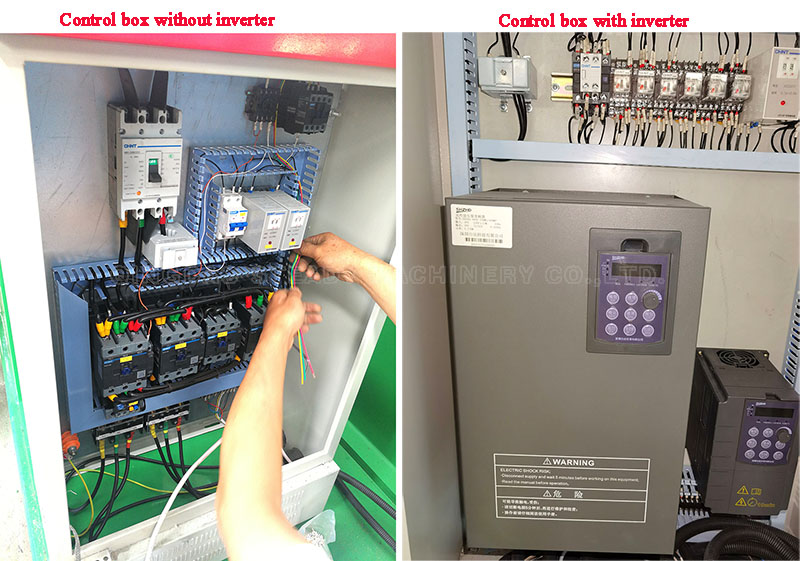

Control Box

Normally it's CHNT brand. If customers want other band, just tell us. And if customers want to change speed, there are frequency speed control machine for choice, the machine has inverter in control box.

Rollers, our rubber open mixing mill machine adopts chilled hard cast iron raw material:

Rubber mixer is one of the important equipment used in the rubber processing industry for mixing, plasticization, dispersion and other processes. It mainly consists of two relatively rotating drums, which achieve the purpose

of mixing by squeezing and shearing the rubber material through these two drums.

So the roller is a very important component of the rubber mixer:

1. * * Cold hard cast iron * *: This is a material description that refers to cast iron materials that have undergone special treatment. Cold hard cast iron (also known as cold hard iron or wear-resistant cast iron) has high hardness

and good wear resistance, making it an ideal material for manufacturing open mill drums. Because during the refining process, the drum needs to withstand continuous wear and compression of rubber materials, the use of

cold hard cast iron can effectively extend the service life of the drum and reduce maintenance costs.

2. Mirror roller: This is a description of the surface condition of the roller. Mirror surface means that the surface of the drum has been finely processed and polished, achieving a very smooth surface effect similar to a mirror.

This approach has the following benefits:

-* * Reduce adhesion * *: The mirror smooth surface of the drum can effectively reduce the adhesion of rubber materials during the mixing process, which helps to improve production efficiency and product quality.

-* * Uniform mixing * *: A smoother surface can make the rubber material more evenly distributed between the rollers, which is conducive to material dispersion and mixing during the mixing process, and improves the mixing

effect.

-Easy to clean: The mirror roller is easier to clean after use, maintaining the hygiene conditions of the equipment, which is particularly important for the production of certain rubber products that have strict requirements for

cleanliness.

In summary, a rubber open mill equipped with a cold hard cast iron mirror roller combines the high wear resistance of the material and the high smoothness of the surface, aiming to improve production efficiency, ensure mixing

quality, and extend the service life of the equipment. It is one of the high-end configurations in the rubber processing industry.

pictures of rubber open mixer

Machining work of the groove rollers

Machine Installation

Press crushing work of rubber cracker/shredder machine

Press crushing work of rubber cracker/shredder machine

Loding Container Export of various model/type rubber open mixing mill

Just contact us

Comments: