A food sterilization autoclave, also known as a food sterilizer or retort, is a specialized piece of equipment used in the food industry for the sterilization of packaged food products. It employs heat, pressure,

and steam to eliminate harmful microorganisms, including bacteria, viruses, and fungi, thereby extending the shelf life and ensuring the safety of the food.

Here are the key features and components of a food sterilization autoclave:

1. Autoclave Chamber: The autoclave chamber is a sealed, pressure-resistant vessel where the food packages are placed for sterilization. It is typically made of stainless steel or other materials that can withstand high pressure

and temperature.

2. Steam Generation System: Autoclaves are equipped with a steam generation system that produces high-pressure steam. The steam is generated by heating water using electrical heating elements or steam boilers.

The high-pressure steam is then injected into the autoclave chamber.

3. Temperature and Pressure Control: The autoclave is equipped with temperature and pressure control systems to ensure precise control over the sterilization process. These systems monitor and regulate the temperature and

pressure levels inside the chamber to achieve the desired sterilization conditions.

4. Cooling System: After the sterilization process is completed, the autoclave may have a cooling system to rapidly cool down the food packages. This helps to prevent overcooking and maintains the quality of the food.

5. Safety Features: Food sterilization autoclaves are equipped with various safety features to protect operators and prevent accidents. These features may include pressure relief valves, emergency stop buttons, interlock systems,

and alarms to ensure safe operation.

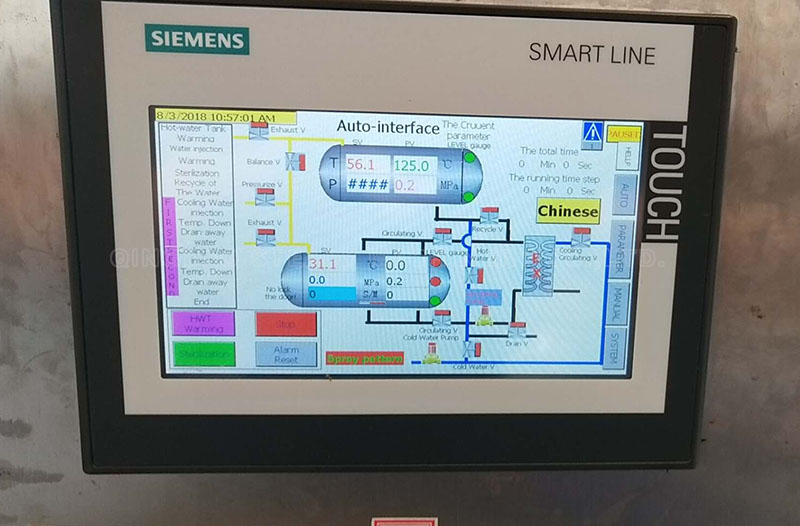

6. Control and Monitoring System: Autoclaves have control and monitoring systems that allow operators to set and monitor the sterilization parameters, such as temperature, pressure, and time. These systems provide real-time

feedback and ensure consistent and accurate sterilization.

Food sterilization autoclaves are used in the food industry to sterilize a wide range of packaged food products, including canned foods, glass jars, pouches, and cartons. The sterilization process eliminates harmful microorganisms,

such as bacteria and spores, that can cause spoilage or foodborne illnesses. This extends the shelf life of the food, preserves its nutritional value, and ensures its safety for consumption.

Food sterilization autoclaves play a crucial role in maintaining food quality and safety standards in the food processing industry.

Safety Standard: As per China Pressure Vessel National Standard GB150-1998 and TSG R0004-2009 《 Fix Pressure Vessel Safety Technology Supervision Regulations》,

JB/T4731-2005《Steel Made Horizontal Vessel》 and GB150.1-4-2011 National Standard design.

And our tank with thermal keeping layer, which saves energy consumption.

Our machine Advantage is safety, reliable, energy saving, compact structure.

Below is a common model for your reference, if you need other models, just feel free to ask us.

Model | RT-700X1200 | RT-1200X3000 |

Diameter | 700mm | 1500mm |

Length | 1200mm | 4000mm |

Electric Heating Power | 40KW | 50KW |

Total Installation Power | 42.2KW | 55KW |

Power Supply | 380V 50HZ 3 phase or as require | 380V 50HZ 3 phase or as require |

Full Volume | 0.46m³ | 3.34m³ |

Effective Volume | 0.24m³ | 1.56m³ |

Main Body Material | S304 | S304 |

Design Temperature | 147℃ | 147℃ |

Working Temperature | 143℃ | 143℃ |

Design Pressure | 0.35Mpa | 0.35Mpa |

Working Pressure | 0.3Mpa | 0.3Mpa |

Test Pressure | 0.44Mpa | 0.44Mpa |

Outside Dimension | 1750*1000*2400mm | 5750x5000x4100 |

Total Weight | About 630kg | About 3700kg |

Above parameters can be customized, we can tailor make machines according to customers' work needs or their main parameters,

and we can adjust other releated parameters to a most reasonable valume.

Detail Images:

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put one for a reference.

Control Box

CHNT brand, it's best brand of China made, works accurate and stable. When customers have different power voltage supply, we put a transformer into the control box.

Tank body, we use SUS304 as raw material

Food-grade stainless steel 304, also known as 18/8 stainless steel, is a type of stainless steel that is commonly used in food processing, storage, and handling applications. It is known for its excellent corrosion resistance, durability,

and hygienic properties, making it suitable for contact with food and beverages.

Here are some key characteristics and properties of food-grade stainless steel 304:

1. Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion and oxidation, even in harsh environments. It resists the attack of acids, alkalis, and many organic compounds, making it suitable for use in food processing

and storage facilities.

2. Hygienic Properties: Stainless steel 304 has smooth, non-porous surfaces that are easy to clean and sanitize, reducing the risk of bacterial growth and contamination. It is commonly used for food preparation surfaces, equipment,

and utensils.

3. Strength and Durability: Stainless steel 304 has excellent mechanical properties, including high tensile strength and good impact resistance. It can withstand high temperatures and heavy usage without deformation or deterioration.

4. Heat Resistance: Stainless steel 304 has good heat resistance, making it suitable for food processing applications that involve exposure to high temperatures, such as cooking, pasteurization, and sterilization.

5. Food Compatibility: Stainless steel 304 is considered safe for use with food and beverages. It does not react with or leach harmful substances into the food, ensuring that the taste, aroma, and quality of the food are preserved.

6. Wide Range of Applications: Food-grade stainless steel 304 is used in various food processing and storage equipment, including tanks, piping, conveyors, mixers, cutting surfaces, and utensils. It is also used in the production of

kitchen appliances, cookware, and food packaging materials.

It's important to note that while stainless steel 304 is generally considered safe for food contact, proper cleaning and maintenance practices are still necessary to ensure food safety. Regular cleaning,

sanitization, and avoidance of harsh chemicals or abrasive cleaners are recommended to maintain the integrity and hygiene of food-grade stainless steel 304 surfaces.

Two ends cover of the tank body, aslo SUS304 steel:

Inside view of food retort autoclave:

autoclave tank loading container export

installation in user's factory

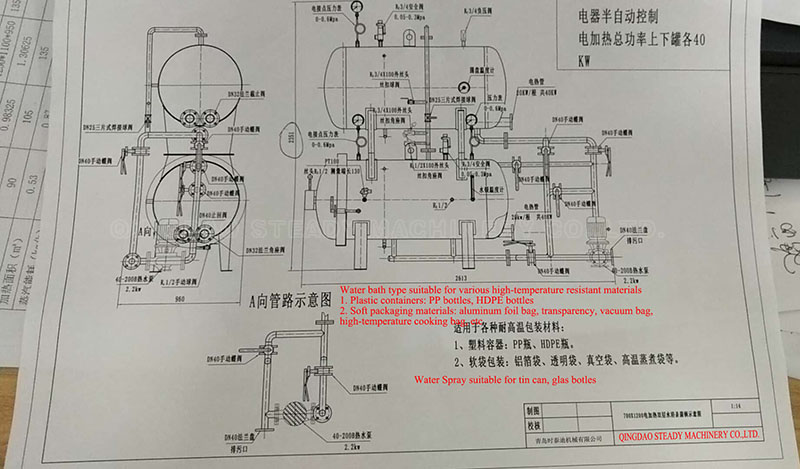

A double layer full automatic food retort sterilization machine's drawing for reference

Just contact us

Comments: