An electric pipe heating rubber vulcanization tank is a specialized piece of equipment used in the rubber industry for vulcanizing rubber products such as hoses, seals, gaskets, and other rubber components.

The tank is designed to provide a controlled environment for the vulcanization process, which involves applying heat and pressure to rubber materials to improve their strength, elasticity, and durability.

In the context of the electric pipe heating rubber vulcanizing tank:

- "Electric" indicates that the tank utilizes electric heating elements to generate the necessary heat for the vulcanization process. Electric heating offers precise temperature control and uniform heating distribution,

which are crucial for achieving consistent vulcanization results.

- "Pipe heating" suggests that there may be a system of pipes within the tank that circulate a heat transfer fluid (such as oil or water) to transfer heat efficiently to the rubber materials being processed.

This helps maintain a stable and uniform temperature throughout the tank.

- "Rubber vulcanizing" refers to the process of curing or hardening rubber through the application of heat and pressure. Vulcanization involves cross-linking the polymer chains in rubber to improve its mechanical properties.

- A "tank" in this context likely refers to a large, enclosed vessel where the vulcanization process takes place. The tank provides a controlled environment where temperature, pressure, and other parameters can be monitored

and adjusted to meet the specific requirements of the rubber being processed.

Overall, an electric pipe heating rubber vulcanizing tank plays a critical role in the rubber industry by enabling the production of high-quality rubber products with enhanced properties through the vulcanization process.

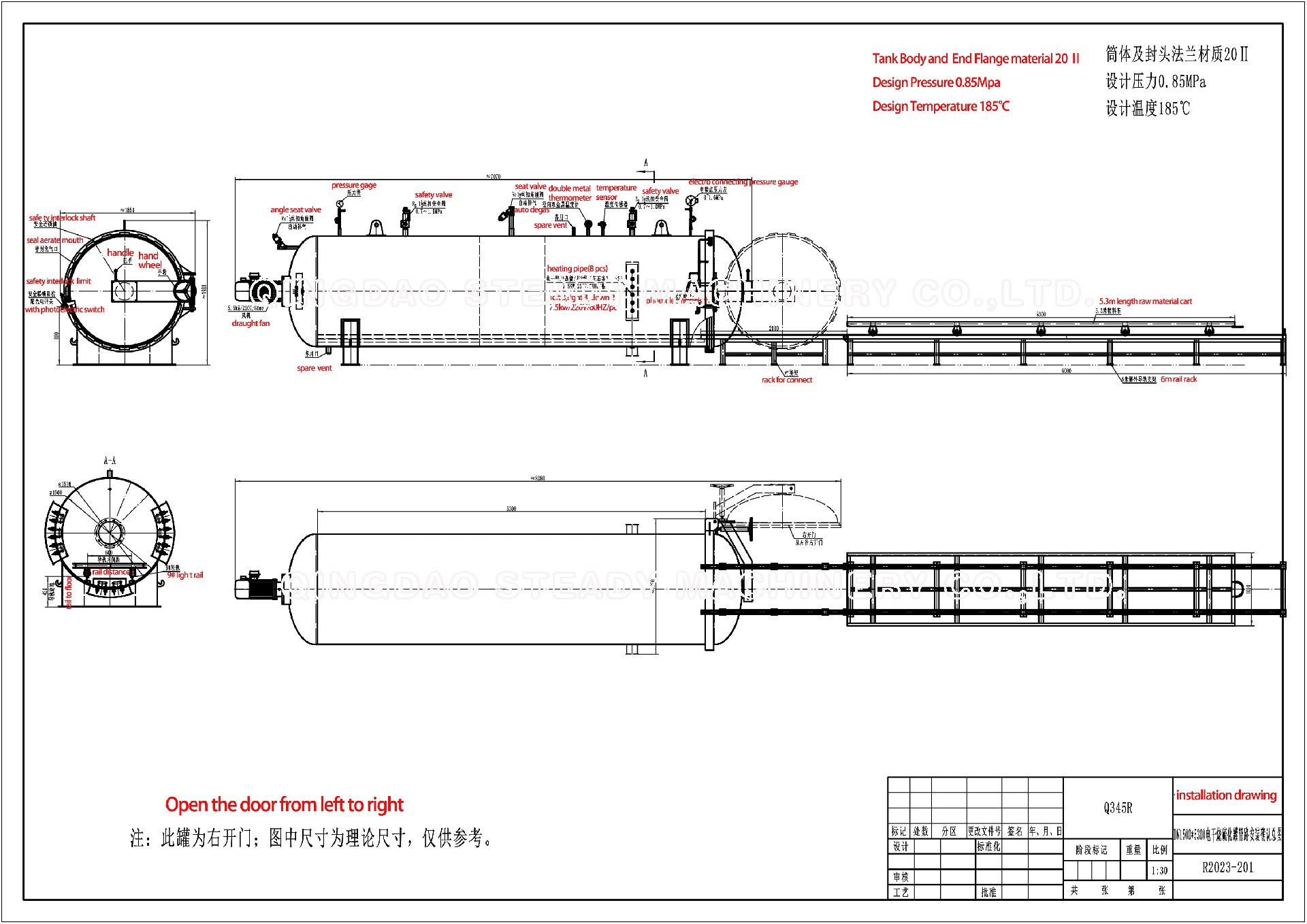

Below is a common model RV-1530(which diameter is 1.5m, working length 3m) for your reference, if you need other models, just feel free to ask us.

Safety Standard: As per China Pressure Vessel National Standard GB150-1998 and TSG R0004-2009 《 Fix Pressure Vessel Safety Technology Supervision Regulations》,

JB/T4731-2005《Steel Made Horizontal Vessel》 and GB150.1-4-2011 National Standard design.

And our tank with thermal keeping layer, which saves energy consumption.

The Advantage is safety, reliable, energy saving, compact structure.

The Advantage is safety, reliable, energy saving, compact structure.

(1) Tank Size(inner diameter/effective length/Total volume):

Φ1500mm/5300mm/8.8m³

(2) Design Pressure: 0.85Mpa

(3) Max. Working Pressure: 0.8Mpa

(4) Pressure Test: 1.09Mpa

(5) Design Maximum Operating Temperature: 180℃

(6) Normal Working Temperature: room temperature~170℃

(7) Power Supply: 220V, 60HZ,3phase or as customer’s require

(8) Heating Method: just Electric pipe heating, without water or steam

(9) Heating Medium: air

(10) Total Power: 64KW

(11) Can Body Material: Q345R/8mm thickness

(12) Door Open Method: Manual(fast) Open

(13) Safety Method: Tank door double safety interlock

(14) Alarm method: setting time run out alarm, super high pressure alarm, sound and light alarm same time.

(15) Sealing Method: Inflate silicone ring(life 1-2 year) with a spare ring.

(16) Temperature error: ±1-2℃

(17) Rail Type: GB12

(18) Floor Space: Floor Space: 6750(L) x 2100(W) x 2050(H) mm

(18) Weight: about 3500kg

All above parameters are subject to change by technology improvement without prior notice.

Above parameters can be customized, we can tailor make machines according to customers' work needs or their main parameters,

and we can adjust other releated parameters to a most reasonable valume.

Detail Images:

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put one for a reference.

Control Box

CHNT brand, it's best brand of China made, works accurate and stable. When customers have different power voltage supply, we put a transformer into the control box, as you can see it from below picture.

Tank body, we use Q345R as raw material

Steel Q345-R, as a widely used low alloy high-strength structural steel, represents the yield strength with "Q" in its grade, while "345" indicates that the yield strength (in megapascals, MPa) of this steel under

standard test conditions reaches 345MPa. The subsequent "R" symbol specifically indicates that the steel is suitable for container manufacturing,

that is, it has good welding performance and certain high-temperature resistance characteristics, and is suitable for the production of pressure vessels, storage tanks and other equipment.

The characteristics of Q345-R steel include:

1. Mechanical properties: In addition to having a yield strength of no less than 345MPa, it also has good tensile strength, generally up to 470-630MPa, as well as good toughness, plasticity, and weldability, ensuring

the safety of components under complex stress states.

2. Chemical composition: As a low alloy steel, Q345-R contains small amounts of alloying elements such as manganese (Mn), silicon (Si), titanium (Ti), niobium (Nb), etc. The addition of these elements can significantly

improve the comprehensive mechanical properties of the steel without significantly increasing its weight, ensuring strength while reducing the structural weight.

3. Corrosion resistance and high temperature resistance: Although Q345 series steel is mainly designed for room temperature environments, Q345-R has certain corrosion resistance and resistance to medium and

low temperatures (usually from room temperature to about 400 ℃) through specific composition adjustments and heat treatment, making it suitable for manufacturing containers that can withstand certain temperature and pressure.

4. Processing performance: Good cold forming and welding performance make Q345-R easy to process into various complex shaped components, meeting different engineering needs, especially in the fields of chemical, petroleum,

energy, etc. It has a wide range of applications.

In practical applications, Q345-R steel needs to undergo strict quality control and testing to ensure that its various performance indicators comply with relevant national standards (such as GB/T 713), in order to ensure its safety

and reliability under design and usage conditions. Whether it's building large oil storage tanks, high-pressure vessels, or industrial boilers, Q345-R is a trusted choice for engineers.

Ends cover of the tank body, aslo Q345R steel:

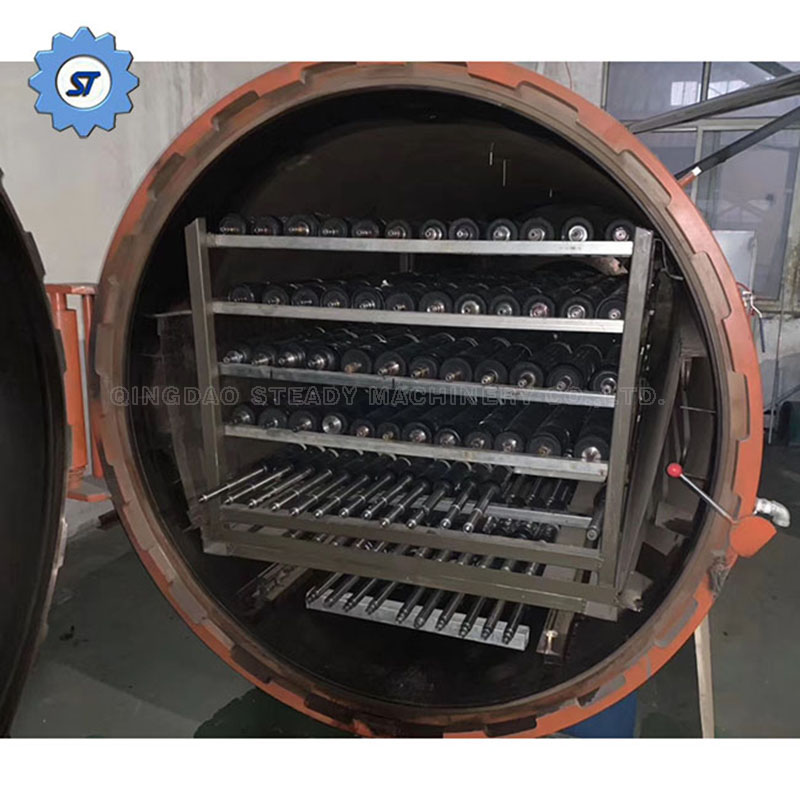

Inside view of steam heating rubber autoclave:

autoclave tank loading container export

work in user's factory

steam heating rubber vulcanizing autoclave drawing for reference

Just contact us

Comments: