Rubber batch off plant, also known as a rubber cooling line or rubber sheet cooling line, is a specialized machine used in the rubber industry for cooling and drying rubber sheets or slabs after the rubber compounding and processing stages.

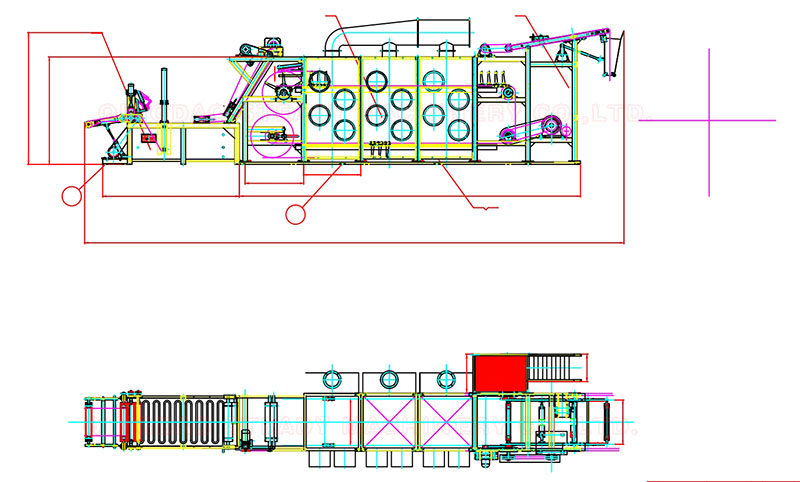

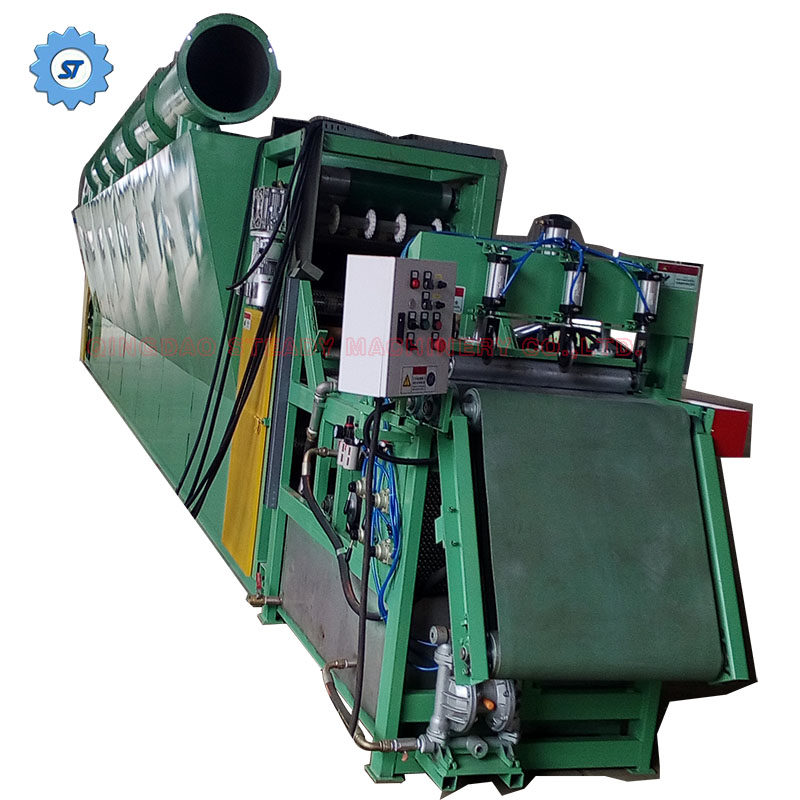

The rubber batch off plant consists of several major components, including a cooling unit, a conveyor system, and a cutting system.

The cooling unit is responsible for cooling the rubber sheets or slabs after they have been processed or molded. It typically consists of a series of cooling drums or cooling belts. The rubber sheets are fed onto the cooling unit, and they pass through the cooling drums or belts, where chilled water or air is applied to rapidly cool and solidify the rubber.

The conveyor system transports the rubber sheets through the cooling unit. It is designed to handle the weight and dimensions of the rubber sheets and ensure a smooth and continuous flow. The conveyor system may have adjustable speed controls to regulate the cooling time and allow for different thicknesses of rubber sheets.

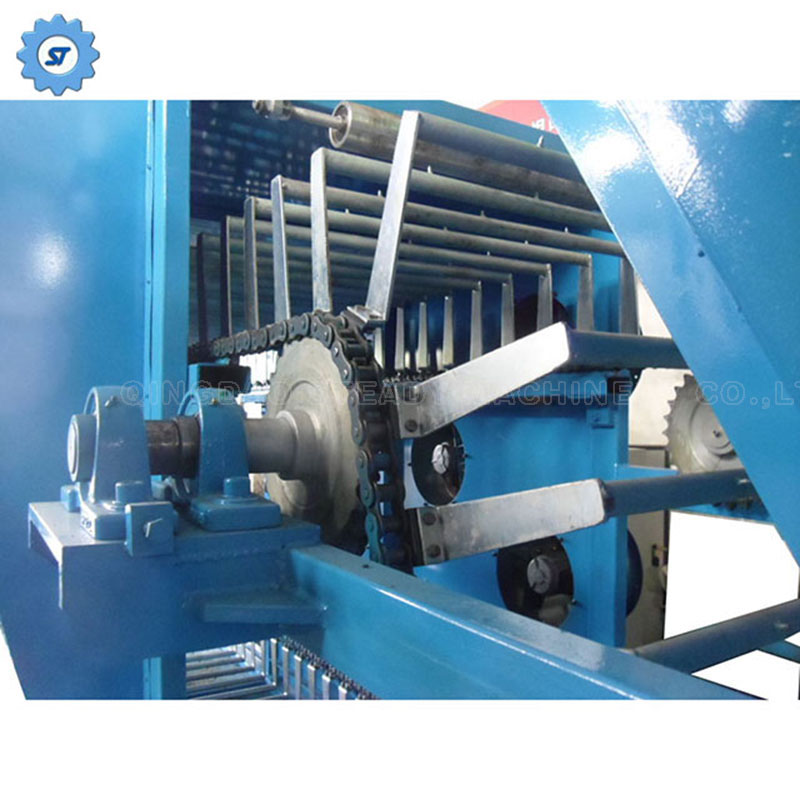

The cutting system is used to cut the cooled rubber sheets into desired lengths or widths. It typically consists of rotating blades or cutting mechanisms that can be adjusted to achieve the desired dimensions.

The cut rubber sheets are then stacked or packaged for further processing or storage.

Rubber batch off plants are essential in the rubber industry as they allow for efficient cooling and drying of rubber sheets, preventing them from sticking together or deforming during the curing process.

They are commonly used in the production of various rubber products, such as rubber flooring, conveyor belts, automotive components, and industrial rubber sheets.

Proper operation, regular maintenance, and adherence to safety guidelines are essential when using a rubber batch off plant to ensure safe and efficient operation, as well as consistent product quality. This includes regular cleaning and inspection of the cooling unit and conveyor system, as well as routine maintenance of the cutting system.

Common Models, if you have any special technical requirements, please just contact us.

Model | XPG-600 | XPG-800 | XPG-900 | ||

Max. rubber sheet width | 600 | 800 | 900 | ||

The thickness of the rubber sheet | 4-10 | 4-10 | 6-12 | ||

Rubber sheeting temperature over room temperature after cooling | 10 | 15 | 5 | ||

Linear speed of taking-in conveyer | m/min | 3-24 | 3-35 | 4-40 | |

Linear speed of sheet hanging bar | m/min | 0.82 | 0.117-1.17 | 4-40 | |

Hanging height of the sheet hanging bar | m | 1000-1500 | 1000-1500 | 1400 | |

Number of cooling fans | Set | 12 | 20 | 18-26 | |

Total power | KW | 13.7 | 28.8 | 18-34 | |

Dimensions | L | 1425 | 16800 | 26630 | |

W | 4500 | 4700 | 3500 | ||

H | 3405 | 3520 | 5630 | ||

Gross weight | T | 11 | 22 | 34 | |

Detail Images of Rubber Open Mixer:

Control Panel

we design different type control panel according to machine needs or customers' requirements, here put one just for your reference. Multi-language.

Control Box

Normally it's CHNT brand. If customers want other band, just tell us. And if customers want to change speed, there are frequency speed control machine for choice, the machine has inverter in control box.

Festoon, or call rubber sheet hanging bar

Sketch drawing for reference

Some pictures for customers reference, if you have any idea in your mind about rubber sheet cooling, just contact us.

Press rubber sheet

Loding Container Export of various model/type rubber open mixing mill

Just contact us

Comments: