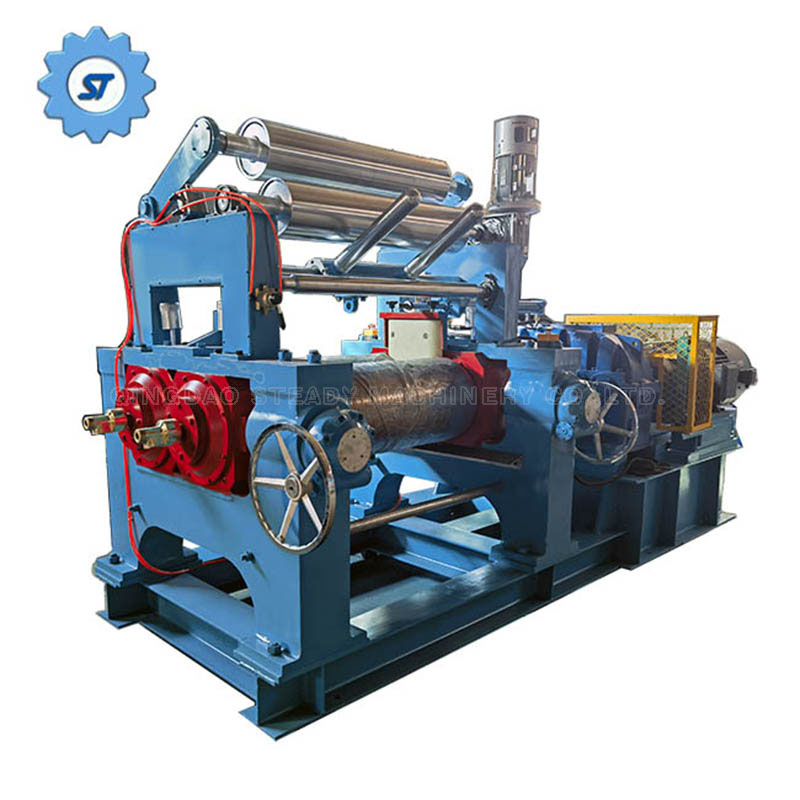

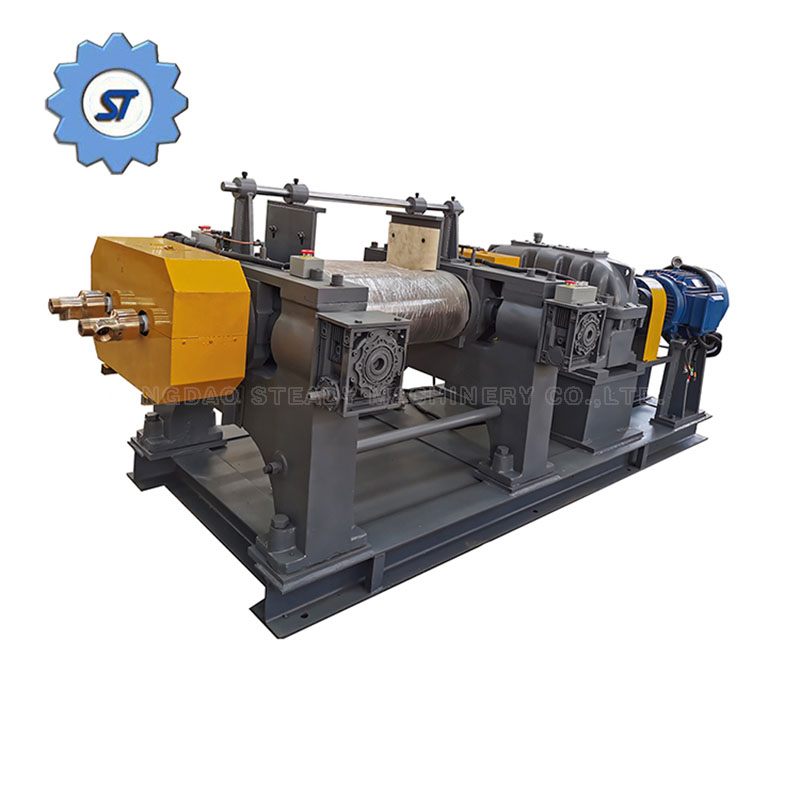

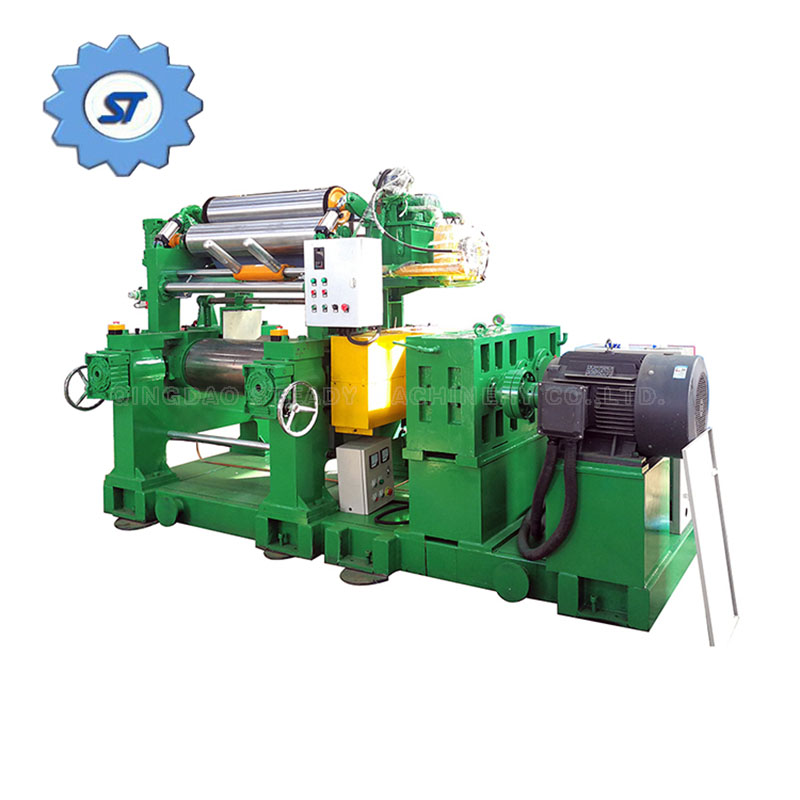

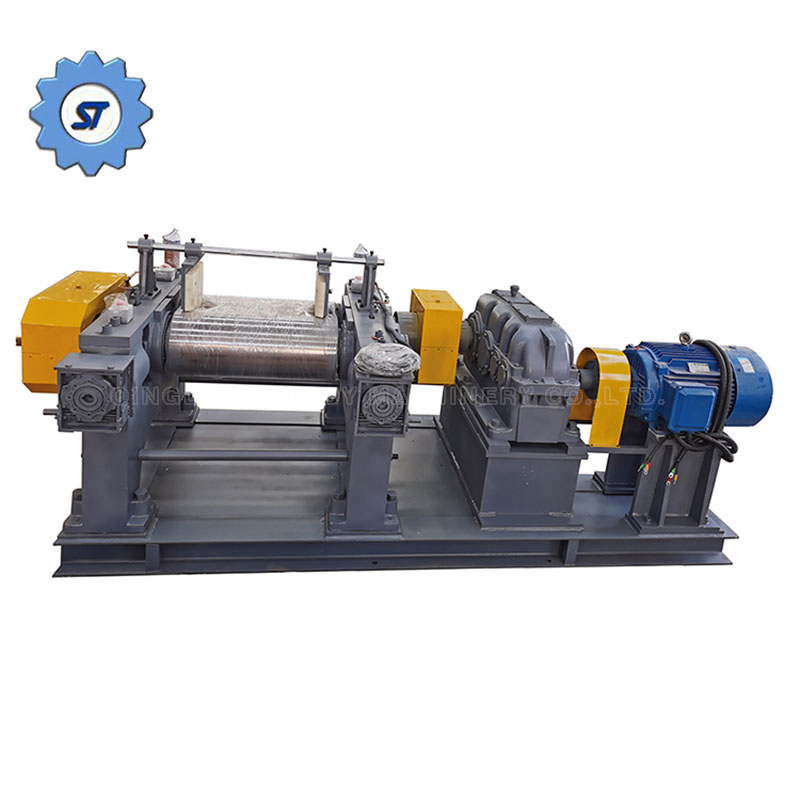

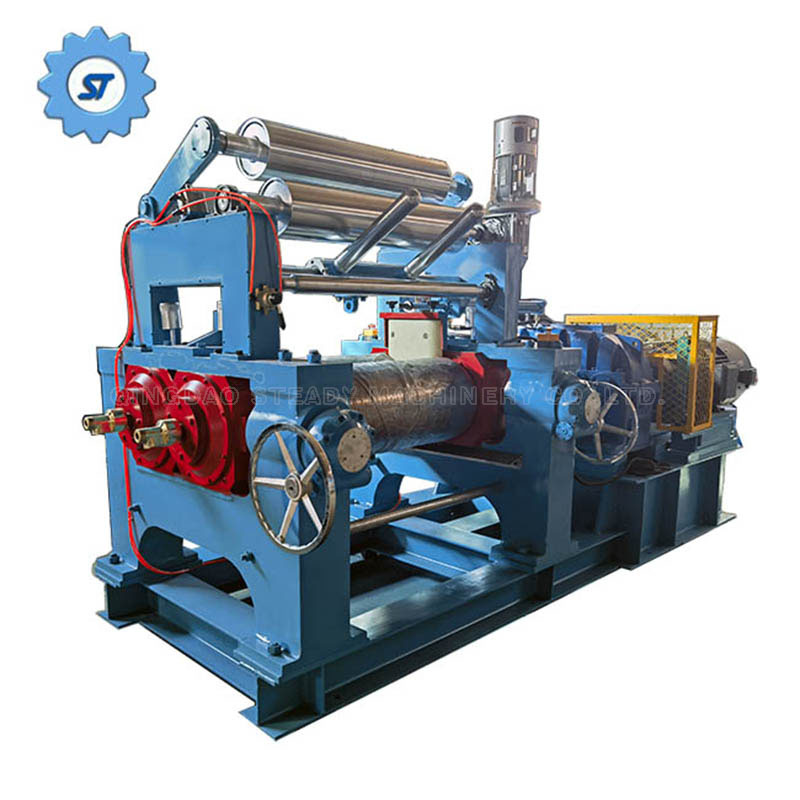

Hard toothed rubber mixer is a mechanical equipment specifically designed for mixing, coloring, and plasticizing materials such as rubber and silicone, widely used in rubber product factories. Its main characteristics include:

1. * * Hard tooth surface design * *: The gear surface has undergone hardening treatment, which improves wear resistance and fatigue strength, can withstand large torque loads, and extends the service life of the equipment.

2. Roller structure: It is usually made of cold hard cast iron or other wear-resistant materials, which have good thermal conductivity. The working temperature can be controlled through an internal water cooling system to

prevent rubber overheating and ensure mixing quality.

3. * * Capacity and Efficiency * *: For example, the XK-250 hard toothed rubber open mill has a roller length of 620mm and a one-time feeding amount of 10-15 kilograms, suitable for small to medium batch production needs.

It has the characteristics of strong mixing ability and low noise, and can efficiently complete the rubber processing task.

4. * * Structure and Maintenance * *: This type of equipment is usually compact in structure, aesthetically pleasing in appearance, and easy to operate and maintain. If a malfunction occurs, minor issues can be resolved by the

user themselves, while major issues require contacting the manufacturer for professional repairs.

5. * * Application scope * *: Suitable for the preparation of raw materials for various rubber and plastic products, including the plasticization of natural rubber, the mixing of raw rubber and compounding agents, as well as the heat

refining and tablet pressing processes of rubber materials.

6. Lubrication and Cooling System: Some models such as XK-400 may be equipped with an open nylon tile dry oil lubrication system to ensure lubrication and reduce wear during machine operation.

7. * * Customization and Service * *: Different manufacturers in the market, such as Qingdao Xincheng Yiming Rubber Machinery Co., Ltd. and Wuxi Latin Machinery Manufacturing Co., Ltd., provide a variety of specifications of

hard tooth surface open mills, and can customize according to customer needs, while providing after-sales service and technical support.

In summary, the hard toothed rubber open mill is an important and efficient equipment in the rubber processing field. It combines durability, high performance, and flexibility to meet the needs of modern rubber product production.

Common Models, if you have any special technical requirements, please just contact us.

| Model | XK-150 | XK-250 | XK-300 | XK-360 | X(S)K-400 | X(S)K-450 | X(S)K-560 | X(S)K-710 |

| Roll Diameter(mm) | ø150 | ø250 | ø300 | ø360 | ø400 | ø450 | ø560 | ø710 |

| Roller Working Length(mm) | 280 | 620 | 750 | 900 | 1000 | 1200 | 1530 | 2300 |

| Front Roll Linear Speed(m/min) | 8 | 15.1 | 15.1 | 16.25 | 18.65 | 24.5 | 27.7 | 26.6 |

| Speed Ratio | 1:1.4 | 1:1.17 | 1:1.27 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.12 | 1:1.09 |

| Max. Nip(mm) | 10 | 10 | 10 | 10 | 15 | 15 | 15 | 15 |

| One Batch Capacity(kg) | 1-2 | 10-15 | 15-20 | 20-25 | 18-35 | 25-50 | 50-65 | 350 |

| Driving Motor Power(KW) | 7.5 | 18.5 | 22 | 30 | 37 | 55 | 95 | 280 |

| Dimension[L×W×H](mm) | 1080*796* 1450 | 3400*1350* 1500 | 3580*1550* 1695 | 3490*1780* 1740 | 4250*1850* 1870 | 5200*2280* 1770 | 6120*2380* 2000 | 7000*2500* 2300 |

| Weight(kg) | 1100 | 3500 | 5205 | 5670 | 7600 | 13000 | 22000 | 35000 |

Detail Images of Rubber Open Mixer:

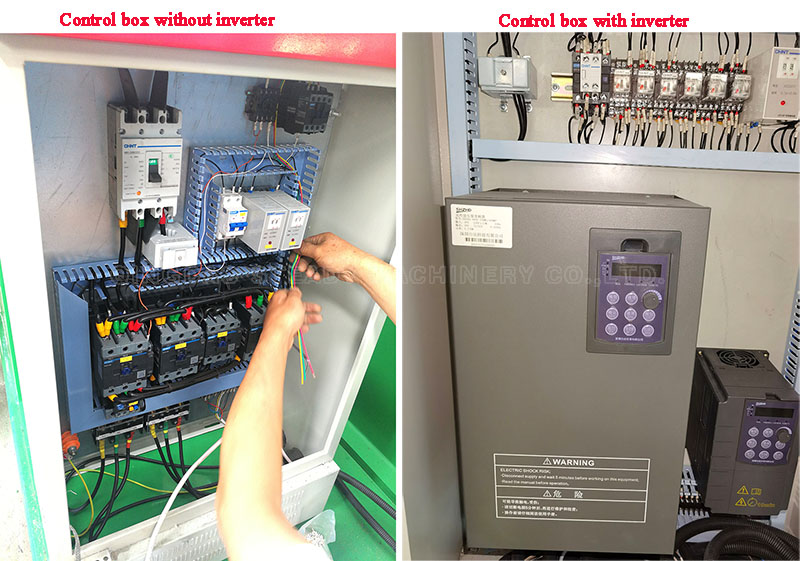

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put a few for your reference.

Control Box

Normally it's CHNT brand. If customers want other band, just tell us. And if customers want to change speed, there are frequency speed control machine for choice, the machine has inverter in control box.

Rollers, our rubber open mixing mill machine adopts chilled hard cast iron raw material:

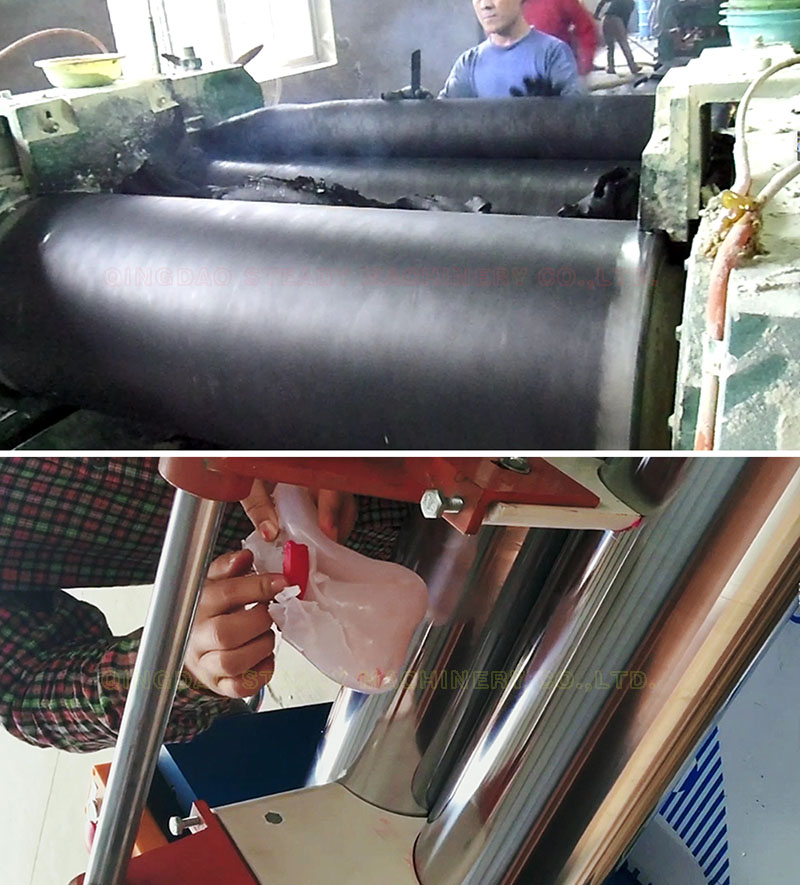

Rubber mixer is one of the important equipment used in the rubber processing industry for mixing, plasticization, dispersion and other processes. It mainly consists of two relatively rotating drums, which achieve the purpose

of mixing by squeezing and shearing the rubber material through these two drums.

So the roller is a very important component of the rubber mixer:

1. * * Cold hard cast iron * *: This is a material description that refers to cast iron materials that have undergone special treatment. Cold hard cast iron (also known as cold hard iron or wear-resistant cast iron) has high hardness

and good wear resistance, making it an ideal material for manufacturing open mill drums. Because during the refining process, the drum needs to withstand continuous wear and compression of rubber materials, the use of

cold hard cast iron can effectively extend the service life of the drum and reduce maintenance costs.

2. Mirror roller: This is a description of the surface condition of the roller. Mirror surface means that the surface of the drum has been finely processed and polished, achieving a very smooth surface effect similar to a mirror.

This approach has the following benefits:

-* * Reduce adhesion * *: The mirror smooth surface of the drum can effectively reduce the adhesion of rubber materials during the mixing process, which helps to improve production efficiency and product quality.

-* * Uniform mixing * *: A smoother surface can make the rubber material more evenly distributed between the rollers, which is conducive to material dispersion and mixing during the mixing process, and improves the mixing

effect.

-Easy to clean: The mirror roller is easier to clean after use, maintaining the hygiene conditions of the equipment, which is particularly important for the production of certain rubber products that have strict requirements for

cleanliness.

In summary, a rubber open mill equipped with a cold hard cast iron mirror roller combines the high wear resistance of the material and the high smoothness of the surface, aiming to improve production efficiency, ensure mixing

quality, and extend the service life of the equipment. It is one of the high-end configurations in the rubber processing industry.

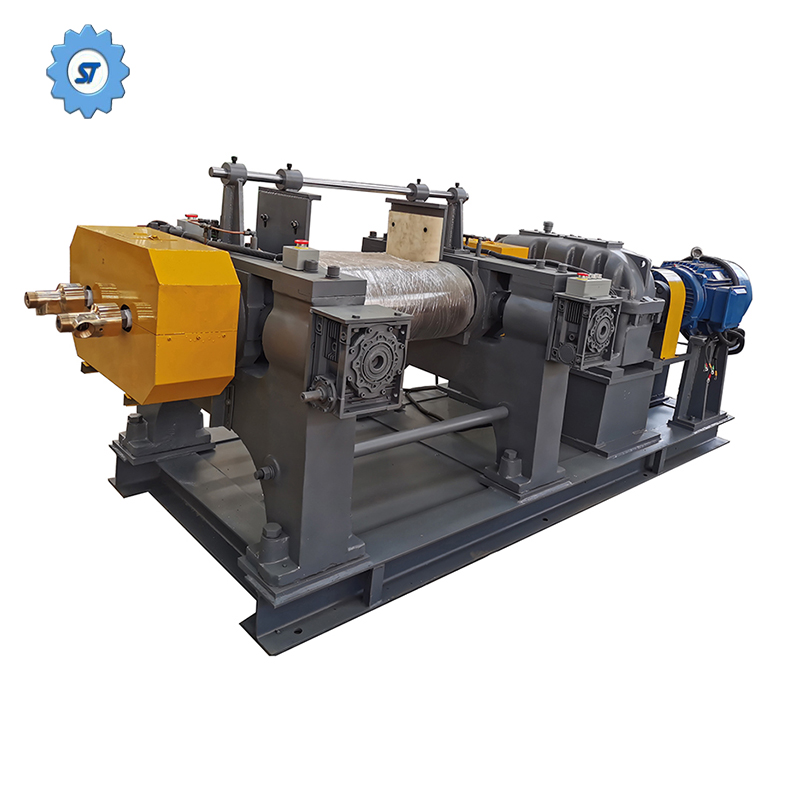

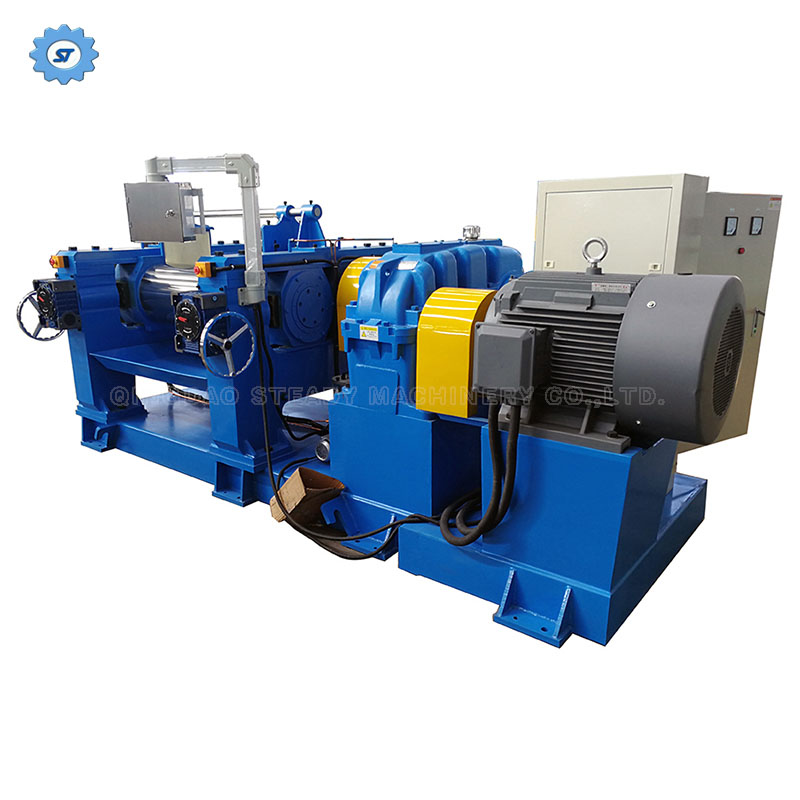

pictures of rubber open mixer

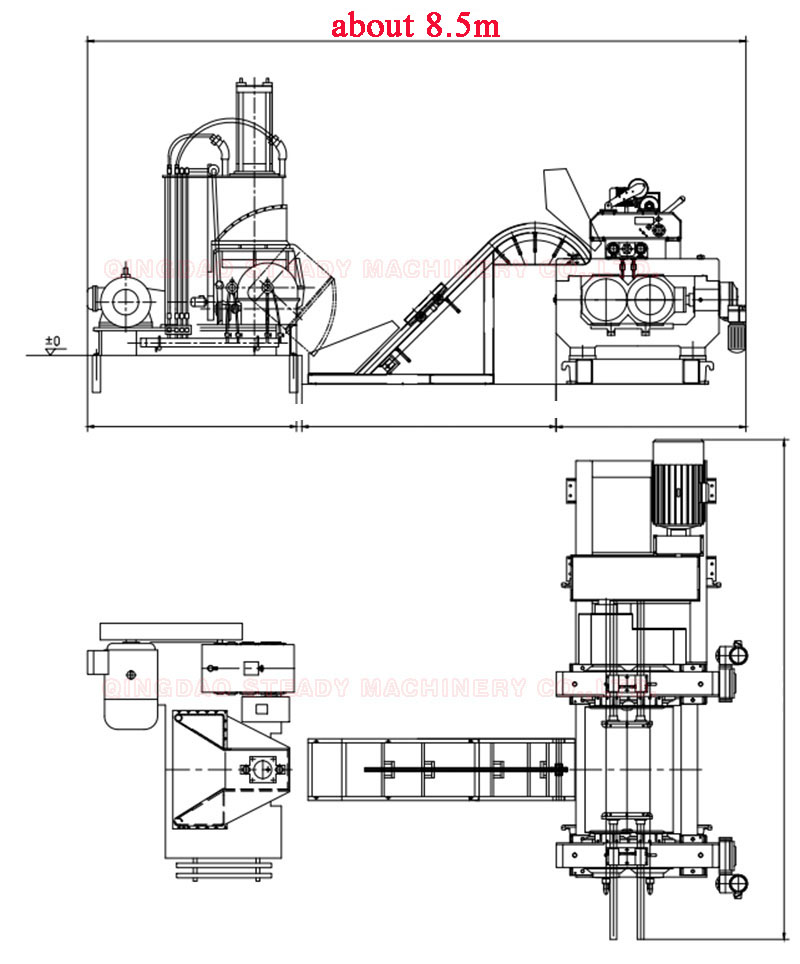

Sketch drawing for reference

Various Type, Size machine pictures for reference

Press rubber sheet

Loding Container Export of various model/type rubber open mixing mill

Just contact us

Comments: