A numerical control (NC) rubber strip cutting machine is an advanced, automated equipment used in the manufacturing industry to precisely cut rubber strips into desired lengths or shapes based on pre-programmed specifications. This type of machinery combines the precision of computer-controlled systems with the versatility needed for processing rubber materials, which can vary in thickness, hardness, and composition. Here's a more detailed look at its features and operation:

### Key Features:

1. **Numerical Control System**: The heart of the machine is its CNC (Computer Numerical Control) system, which allows for precise control over the cutting process. Operators input cutting parameters such as length, width, angle, and shape into the system using a computer interface. The machine then follows these instructions to make accurate cuts.

2. **Automatic Feeding & Alignment**: To ensure consistent and efficient processing, these machines often have automatic feeding mechanisms that align the rubber strip correctly before the cutting process begins. This minimizes material waste and enhances productivity.

3. **High Precision Cutting Tools**: Depending on the type and hardness of the rubber being cut, the machine may use various types of cutting tools such as rotary knives, bandsaws, or lasers. These tools are designed to maintain sharpness and deliver clean, burr-free cuts.

4. **Versatility**: NC rubber strip cutting machines can be programmed to handle different types of cuts, from straight lines to complex contours. They can also process a wide range of rubber materials, including natural rubber, silicone, neoprene, EPDM, and others.

5. **Safety Features**: Given the high-speed and potentially hazardous nature of the cutting operation, these machines are equipped with safety interlocks and barriers to protect operators from injury.

6. **Efficiency and Productivity**: By automating the cutting process, these machines significantly increase production speed and reduce labor costs compared to manual cutting methods. They also offer consistent quality and minimal material waste.

### Operation Process:

1. **Programming**: The operator inputs the required dimensions and cutting pattern into the CNC controller using CAD/CAM software.

2. **Material Loading**: The rubber strip is loaded onto the machine's feeding mechanism, which automatically aligns it for cutting.

3. **Cutting**: The machine's cutting tool, guided by the CNC program, moves along the predetermined path to cut

Common Models, if you have any special technical requirements, please just contact us.

Model | RC-600 | RC-700 | |

Max. Cutting Width(mm) | 600 | 700 | |

Max. Cutting Material Thickness(mm) | 20 | 20 | |

Cutter Material | High carbon rapid steel(W6Mo5Cr4V2) | High carbon rapid steel(W6Mo5Cr4V2) | |

Feeding Length(m) | 0-9999 | 0-9999 | |

Motor Power(kw) | 3.0kw(380V,50HZ, 3phase) | 3.0kw(380V,50HZ, 3phase) | |

Adjust Method | Touch Screen with PLC | Touch Screen with PLC | |

PLC Brand and Model | XINJE xc2-14t-e | XINJE xc2-14t-e | |

Touch Screen Brand | MCGS TPC7062TD | MCGS TPC7062TD | |

Step Motor Model | 110byg-20n.m | 110byg-20n.m | |

Machine Size(mm) | 1100*1350*1200 | 1100*1350*1200 | |

Weight(kg) | 330 | 330 | |

Color | White or require | White or require |

Detail Images of Rubber Sheet Cutting Machine:

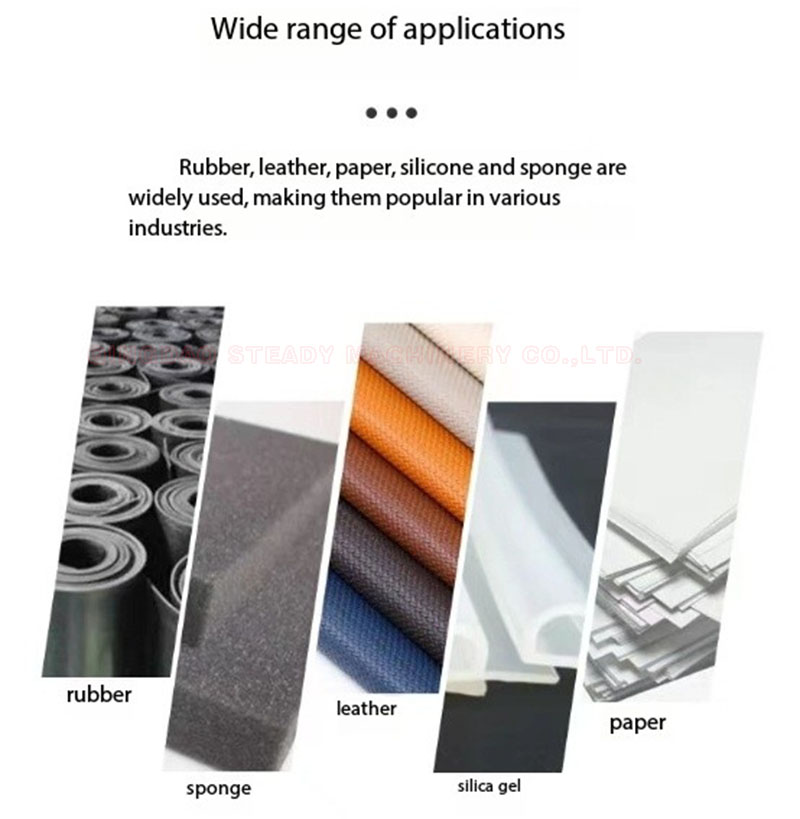

The machine's alpllication range is very wide, it can be used to cut rubber, leather, paper, silicone and sponge.

Just contact us

Comments: