A rubber belt connection machine, also known as a rubber belt joining machine or belt bonding machine, is a specialized tool used for connecting or bonding rubber belts together. It is commonly used in industries where rubber belts are employed for conveying materials, such as in mining, agriculture, packaging, and manufacturing.

The rubber belt connection machine allows for the seamless joining of two separate sections of rubber belts, creating a continuous and durable belt without the need for mechanical fasteners or splicing techniques. It is particularly useful when dealing with long or wide belts that require a strong and smooth connection.

The machine typically consists of a machine frame, heating elements, pressure plates, and controls. The specific design and features may vary depending on the manufacturer and model.

The connection process begins by preparing the belt ends to be joined. This may involve trimming, skiving, and cleaning the belt surfaces to ensure a proper bond. The prepared belt ends are then placed in the machine, which aligns and secures them in position.

The machine applies heat and pressure to the belt ends to facilitate the bonding process. The heating elements in the machine generate heat that softens the rubber material, allowing it to bond together. Simultaneously, pressure plates or clamps exert pressure on the heated belt ends, ensuring a uniform and strong connection.

The temperature, heating time, and pressure during the connection process are typically controlled using the machine's control system. This helps ensure optimal bonding conditions for a reliable connection.

Rubber belt connection machines are available in various sizes and configurations to accommodate different belt widths and thicknesses. They offer advantages such as efficient and seamless belt connection, improved belt strength and durability, and reduced downtime for belt replacements.

It's important to note that the specific operation and features of a rubber belt connection machine may vary depending on the manufacturer and model.

* * Application Scope of rubber conveyor belt hot vulcanizing press connection machine * *: Suitable for vulcanization operations of conveyor belt joints in various industrial environments including metallurgy, chemical industry, mines, power plants, ports, etc. It is particularly important for widened, ultra long distance, and high-strength conveyor belts, which can significantly improve the quality of joints, extend the service life and operating efficiency of conveyor belts.

Common Models, if you need other models or have other special technical requirements on size, pressure, working layer number, please just contact us.

|

Model |

Belt Width |

SplicingDimension(mm) |

HeatingPlate Size(mm) |

Power(kw) |

Overall Dimension(cm) |

Weight(kg) |

|

ST-650 |

650 |

650x830 |

810x830 |

10 |

140x83x63 |

440 |

|

650x1000 |

810x1000 |

12 |

140x100x63 |

530 |

||

|

ST-800 |

800 |

800x830 |

960x830 |

12 |

150x83x63 |

515 |

|

800x1000 |

960x1000 |

14 |

150x100x63 |

630 |

||

|

ST-1000 |

1000 |

1000x830 |

1160x830 |

15 |

170x83x63 |

600 |

|

1000x1000 |

1160x1000 |

17 |

180x100x63 |

715 |

||

|

ST-1200 |

1200 |

1200x830 |

1360x830 |

17 |

192x83x75 |

800 |

|

1200x1000 |

1360x1000 |

20 |

198x100x75 |

912 |

||

|

ST-1400 |

1400 |

1400x830 |

1560x830 |

20 |

215x83x75 |

885 |

|

1400x1000 |

1560x1000 |

23 |

220x100x75 |

1050 |

||

|

ST-1600 |

1600 |

1600x830 |

1760x830 |

22 |

240x83x80 |

1130 |

|

1600x1000 |

1760x1000 |

26 |

245x100x80 |

1325 |

||

|

ST-1800 |

1800 |

1800x830 |

1960x830 |

25 |

260x83x90 |

1420 |

|

1800x1000 |

1960x1000 |

29 |

265x100x90 |

1630 |

||

|

ST-2000 |

2000 |

2000x830 |

2160x830 |

27 |

280x83x90 |

1560 |

|

2000x1000 |

2160x1000 |

32 |

285x100x90 |

1824 |

||

|

ST-2200 |

2200 |

2200x830 |

2360x830 |

30 |

300x83x98 |

1720 |

|

2200x1000 |

2360x1000 |

35 |

305x100x98 |

2030 |

Detail Images of Conveyor Belt Splicing Joint Machine:

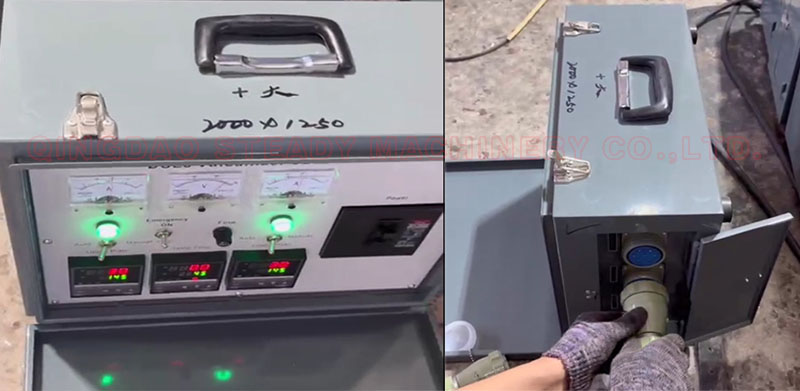

Control Box

CHNT Brand electronics are adoted, works accurate and stable.

* * Intelligent Control * *: Modern conveyor belt joint machines are usually equipped with precision digital automatic control boxes, which can achieve automation of temperature and pressure control, easy operation, and high reliability. The connection between the electrical control box and the host adopts integrated plugins and multi-core cables, which are easy to install and maintain.

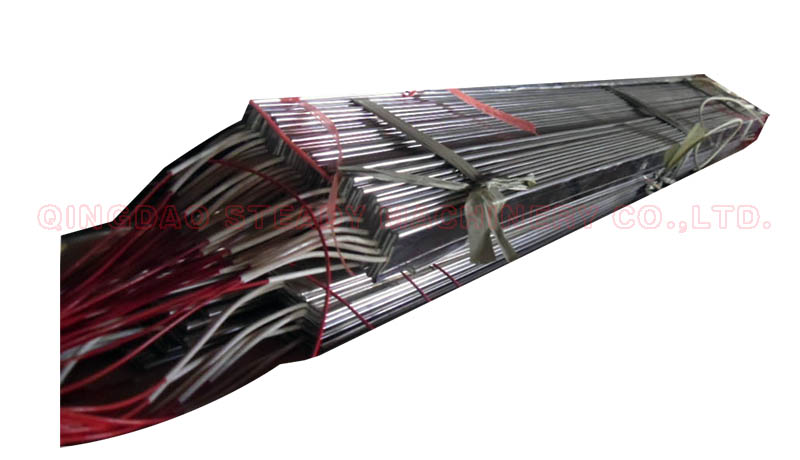

Heating Platen, the heating platen can be designed with or without the fast water cooling tunnel.

* * Temperature Control * *: Used in conjunction with aluminum alloy heating plates, the thermal couple(also called temperature sensor) one end inserted into the heating platen, another end connect with the control box, through the plug and socket, they connect each other to test, transfer and control the temperature. These heating plates are also made of high-purity and high thermal conductivity aluminum alloy materials, which can quickly and evenly heat, ensuring that the rubber in the joint area can be fully vulcanized, enhancing the firmness and durability of the joint.

Heating Element

High quality heating sheet/strip is adopted in our rubber conveyor belt joint machine, which ensures trouble free and long service life. And it's easy to replacement.

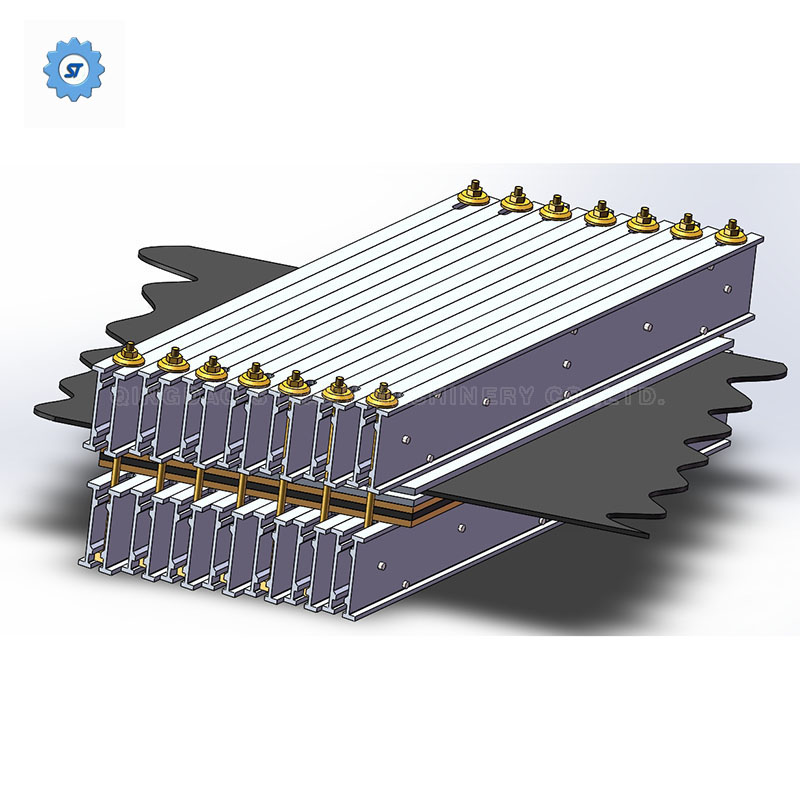

Pressure adding rubber water pressure bag/chamber :

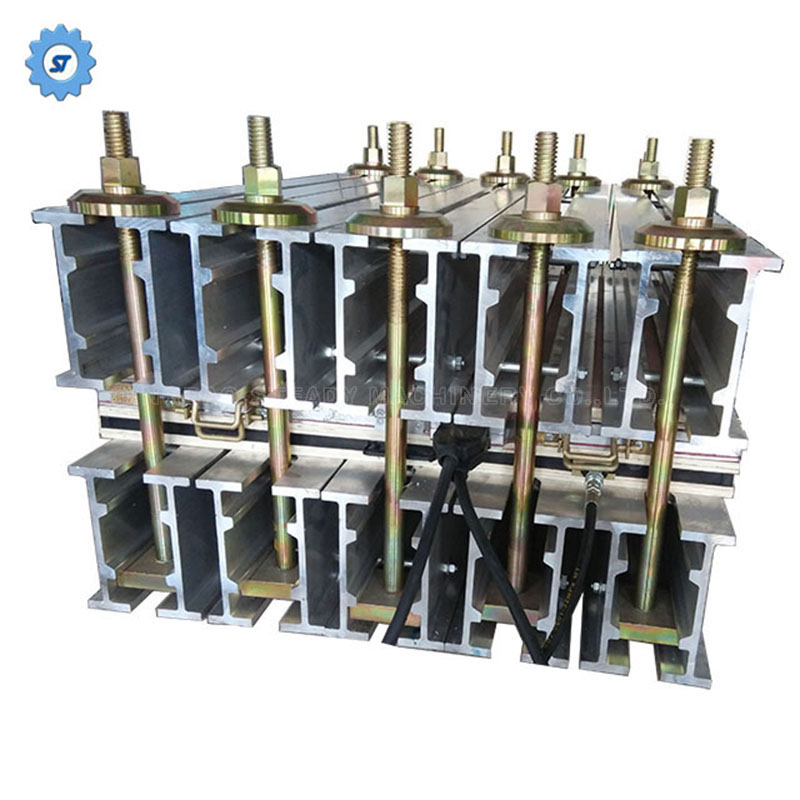

The aluminum alloy frame water pressure plate of the conveyor belt joint machine is a key component in the vulcanization equipment, mainly used to provide uniform and strong pressure during the vulcanization process of the conveyor belt joint, to ensure that the joint parts can be firmly bonded together. Below is a brief introduction to some of the main features and functions of this component:

1. * * Material * *: The frame is usually made of high-strength and highly plastic aluminum alloy materials. This material is not only lightweight, but also has good mechanical properties and thermal conductivity, which helps the overall lightweight and efficient operation of the machine.

2. * * Water pressure plate design * *: As a pressure application component, the water pressure plate applies uniform pressure to the conveyor belt joint through internal water injection and pressurization. It has the characteristics of large expansion amplitude, uniform pressure distribution, and strong pressure bearing capacity, which can ensure that every part of the joint area can receive the same and sufficient pressure during the vulcanization process, thereby forming high-quality joints.

3. * * Pressure Supply System * *: The pressure of the water pressure plate is usually supplied by an electric pump or a manual pump, which can be flexibly adjusted and maintain a stable water pressure, usually up to 1.0-3.0 MPa, to meet the vulcanization needs of conveyor belts with different thicknesses and strengths.

High quality water pump, easy to use, and not easy have problem

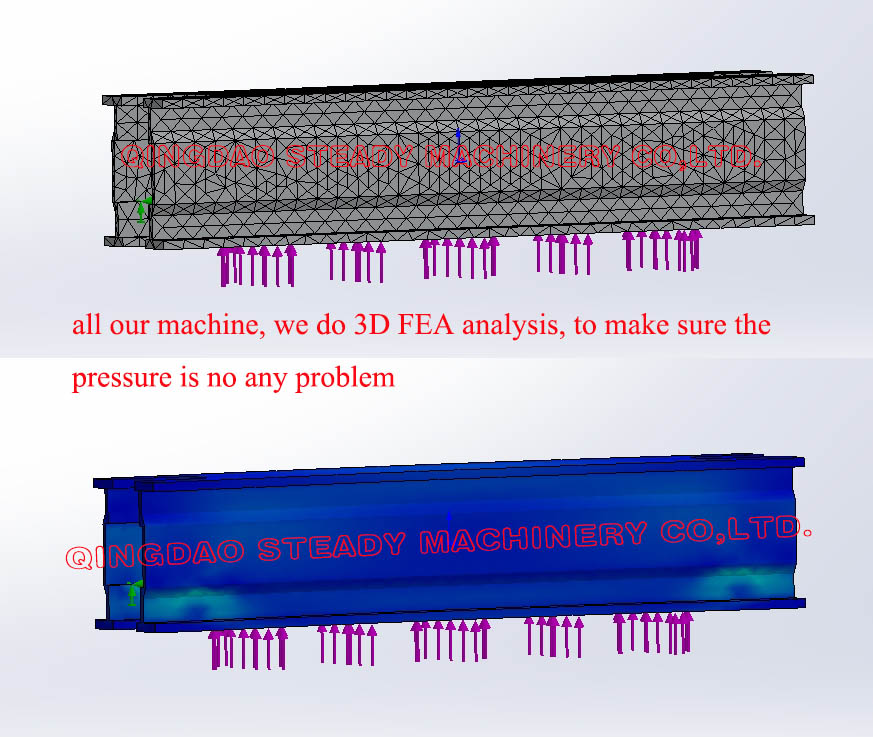

3D design and FEA( Finite Elements Analysis) , plus our 20+ really production experience in the field, ensure our machine is high precision and enough strength to meet work needs, long service life and trouble free.

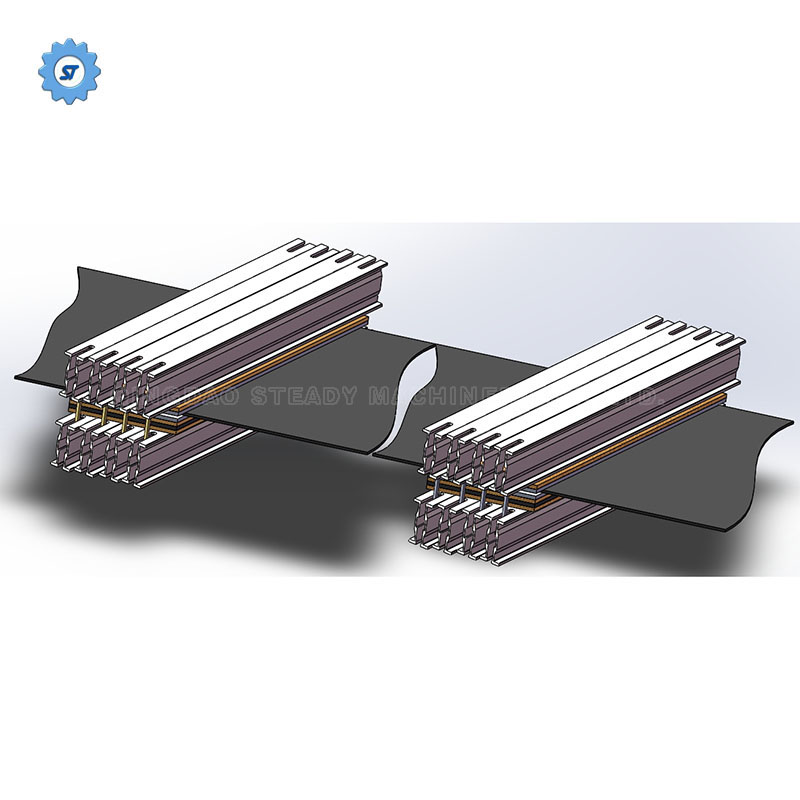

Below machine, can used as two sets seperate small machine, and when put close together, they can be use as a big set rubber conveyor belt splicing joint machine.

The use of the machine is very easy, just plug the the male plug into socket, switch on the power, then you can use the machine.

Rubber Belt Splicing Joint Machines Working in Various Spots

Just contact us

Comments: