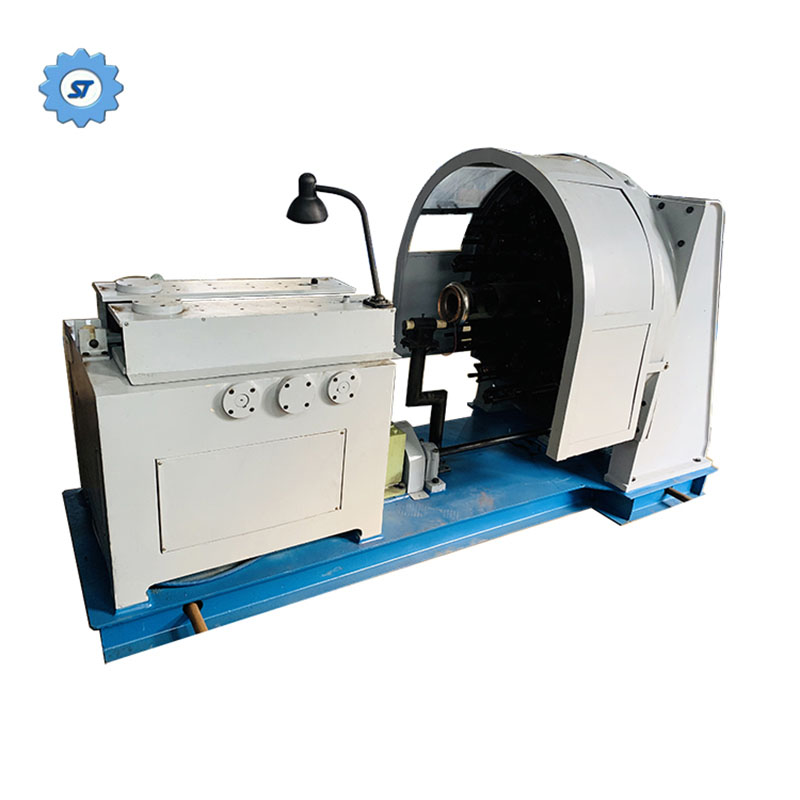

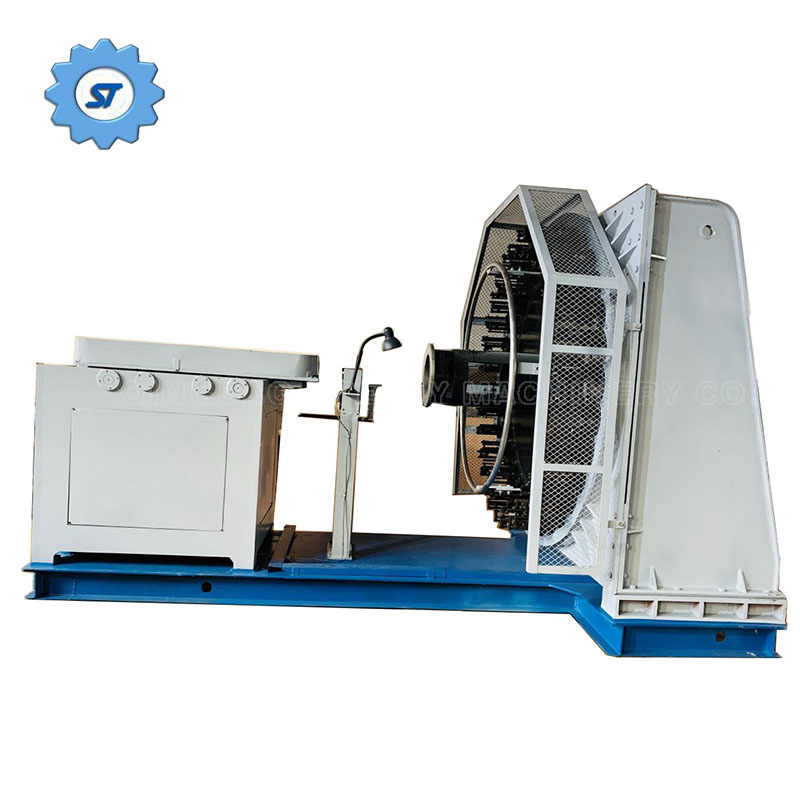

A steel wire hose braiding machine, also known as a steel wire braider or wire braiding machine, is a specialized machine used in the production of steel wire reinforced hoses. These hoses are commonly used in industries

such as automotive, aerospace, and hydraulic systems, where high-pressure applications require additional strength and durability.

Here are the key features and components of a steel wire hose braiding machine:

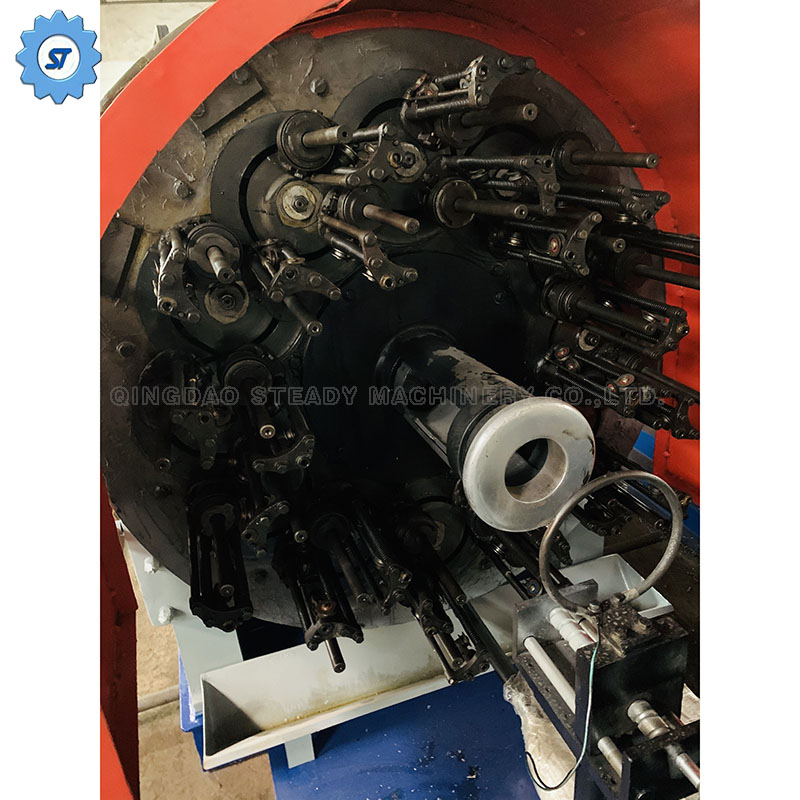

1. Braiding Head: The machine consists of a braiding head that holds and guides the steel wires during the braiding process. The braiding head typically has multiple spools or bobbins to feed individual steel wires.

2. Steel Wire Feeding System: The machine includes a steel wire feeding system that feeds the wires from the spools or bobbins into the braiding head. The feeding system ensures the proper tension and alignment of the wires during the braiding process.

3. Braiding Carrier: The braiding carrier is a rotating component in the braiding head that holds and moves the steel wires to create the braided pattern. It typically consists of multiple carriers that move in a circular motion, interlacing the steel wires to form the braided reinforcement layer of the hose.

4. Wire Tensioning System: To maintain proper tension on the steel wires during braiding, the machine may have a wire tensioning system. This system ensures that the wires are evenly tensioned and tightly braided, providing optimal strength and stability to the hose.

5. Speed Control: The machine allows for the adjustment of braiding speed to accommodate different production requirements or specific hose designs. This can be achieved through variable speed drives or other speed control mechanisms.

6. Cutting System: Once the braiding is complete, the machine may include a cutting system to cut the braided wire-reinforced hose into specific lengths. This can be achieved through cutting blades or other cutting mechanisms.

Steel wire hose braiding machines can be customized to produce hoses of various sizes, reinforcement patterns, and wire configurations. The braiding process enhances the strength, flexibility, and resistance to pressure and external forces of the hoses. These machines play a crucial role in the manufacturing of high-quality steel wire reinforced hoses used in a wide range of industrial applications.

We have different model and size for choice of steel wire reinforce high press hose braiding machine.

Below take 24 spindle as a sample, just contact and tell us your work needs, we can recommend a most appropriate machine for you.

Model | HWB-24 |

Spindle Number | 24 |

Station Number | Single |

Wire Diameter | Steel wire 0.16mm-0.50mm Stainless steel wire 0.20mm-0.50mm |

Shaft Size | Flange diameter:83mm |

Spindle body diameter:31mm | |

Inner diameter:19.5mm | |

Surface movement width:200mm | |

Total length:208mm | |

Spindle Rotation Speed | 16rpm |

Tension | 3.5——13kg |

Single Strand Wire Number | 4——12pcs |

Hose Diameter | 10——30mm |

Braiding Pitch/step | 22——69mm |

Braiding Angle/tight angle | 54°44′ |

Motor Power | 4KW |

Traction Speed | 21——66m/h |

Traction Motor Power | 4KW |

Complete with pulling crawler | |

Machine Size | 2700*1200*1600mm |

Machine Weight | About 3.1T |

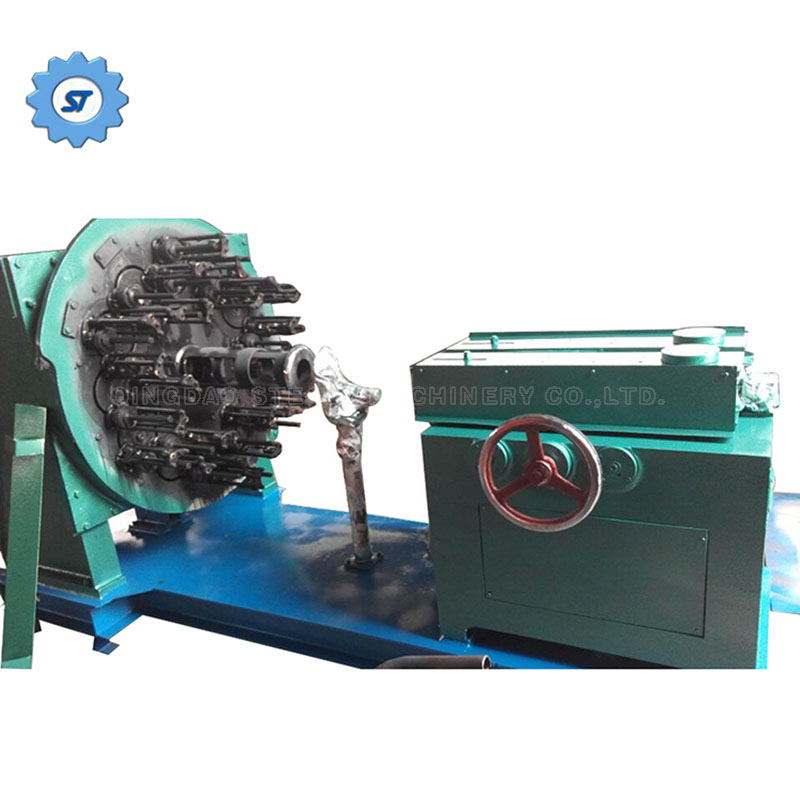

Below is steel wire stranding bunching machine:

Steel wire bunching is a process in which individual steel wires are twisted or braided together to form a bundle or strand. This process is commonly used in the manufacturing of steel wire ropes, cables, and other wire-based products that require increased strength and flexibility.

During the bunching process, multiple individual steel wires are typically fed into a machine that twists or braids them together. The level of twisting or braiding determines the final characteristics of the wire bundle,

including its strength, flexibility, and resistance to fatigue.

Bunching steel wires provides several benefits. It increases the overall strength of the wire bundle, allowing it to withstand higher loads and tensions. Bunching also enhances the flexibility of the wire, making it easier to bend

and maneuver without compromising its structural integrity.

Steel wire bunching is commonly used in various industries, including construction, automotive, aerospace, and marine. Steel wire ropes, for example, are extensively used for lifting, towing, and securing heavy loads.

Just contact and tell us your work needs, we'll provide you a suitable proposal, high quality steel wire braiding machine and auxiliary machines with most reasonable price.

Comments: