A rubber hose extruding machine, also known as a rubber hose extruder or rubber extrusion machine, is a specialized machine used in the production of rubber hoses.

It is designed to extrude and shape rubber materials into continuous lengths of hoses with specific dimensions, shapes, and properties.

Here are the key features and components of a rubber hose extruding machine:

1. Extruder Barrel: The machine consists of an extruder barrel, which is a cylindrical chamber where the rubber material is fed and heated.

The barrel is typically equipped with heating elements or a heating system to melt and soften the rubber compound for extrusion.

2. Extruder Screw: Inside the extruder barrel, there is an extruder screw that rotates and pushes the rubber material forward.

The screw is designed with specific flighting patterns to create pressure and shear forces, facilitating the melting, mixing, and homogenization of the rubber compound.

3. Die Head: The die head is a critical component of the rubber hose extruding machine. It is located at the end of the extruder barrel and shapes the molten rubber into the desired cross-sectional shape of the hose.

The die head has an opening or multiple openings that define the final dimensions and shape of the extruded rubber hose.

4. Cooling System: After the rubber material passes through the die head and is extruded into the desired shape, it needs to be cooled and solidified.

The rubber hose extruding machine typically has a cooling system, which may include water baths, cooling fans, or other methods to rapidly cool down the extruded rubber hose.

5. Puller System: To ensure continuous extrusion and maintain proper tension on the extruded hose, the machine may have a puller system.

The puller consists of belts, rollers, or other devices that grip the extruded hose and pull it at a controlled speed.

6. Cutting and Winding System: Depending on the desired length of the rubber hose, the machine may include a cutting and winding system to cut the extruded hose into specific lengths

and wind it onto spools or reels for further processing or packaging.

Rubber hose extruding machines can be customized to produce hoses of various sizes, shapes, and materials.

They are widely used in industries such as automotive, construction, agriculture, and manufacturing, where rubber hoses are essential for fluid transfer, conveying, and other applications.

The extrusion process allows for the production of seamless and homogeneous rubber hoses with consistent dimensions and properties.

7. Constant Speed or Variable speed drive as per specific requirement.

Motor: frequency speed control motor or DC motor.

8. The advantages of the machine include better plastication result, higher extrusion capability, lower temperature of the outgoing rubber and smooth working, easy operationand maintenance.

9. Rubber hose extruding machine, not only just used in extruding rubber hose/tubes, but when change mold to it, the machine can be used to extrude rubber sheet, inner liner, seals, wire cable, sheath, tiretread, tire side wall, also be used to supply rubber for small size calender.

Cold feed rubber extruder is suitable for extrusion molding of rubber tubes, inner tubes, tire tread, sealing strips and various kinds of other rubber products.

The extruded products have the characteristics of good mixing quality and uniform plasticization.

Pin barrel cold feed rubber extruder has not only made significant improvements in screw structure, but also added pins to teh barrel. It has the characteristics of better plasticization performance, low rubber discharge temperature, and large extrusion volume, and has been increaslingly widely used in rubber industry production.

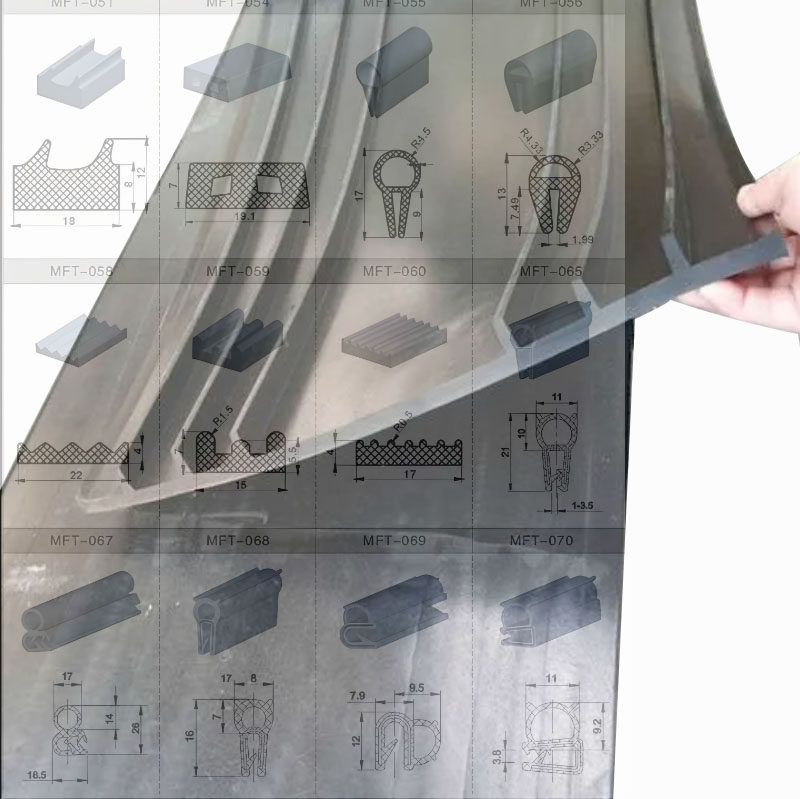

According to customers' requirements, different types machine head can also be customized. By changing machine head, different shape rubber products can be produced.

Cold Feed Pin Barrel type Rubber Extruder, machine head for reference (we can make various shape & size extruder head according to customers' work needs or requirements) :

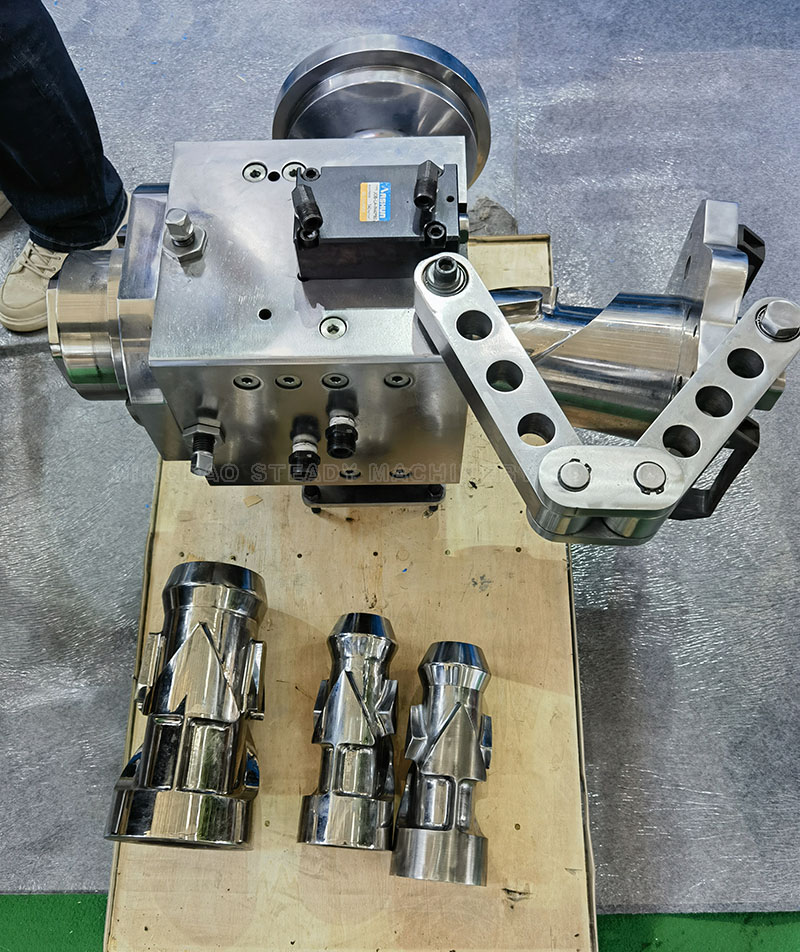

Mold of Rubber Extruding Machine

T-head of Rubber Extruding Machine:

Tire Tread Head of Rubber Extruding Machine:

Various type pins(hardness HRC50-55) of rubber extruding machine:

Advantage of Qingdao Steady Machine's rubber extruding machiner:

Our Screw & Barrel Advantage is as below, ensures our machine is 1.5 ~2 times more durable than other supplier's extruder machines:

The material is: 38CrMOALA

Temper Degree:HB240°~280°

Nitriding Hardness:HV850°~1000°

Nitriding Deepness:0.45~0.7mm

Nitriding Brittleness:≤Grade Ⅱ

Surface Roughness:Ra0.4

Screw Straightness:0.015mm

Hard Chrome Plating after Nitriding:≥900HV

Chrome Thickness:0.05~0.10mm

Two-phase Alloys:HRC56°~65°(nickel-base alloy)

Alloy Deepness:1.5~2.0mm

Control Panel, which is movable on extruder machine, so it's easy for worker to operate in any position around our extruder machine,

and we can put your language beside the buttons.

Control Box, our rubber extruding machine use high quality electronics, ensures the machine working sensitive and reliable.

The speed adjustment is very smooth and stepless.

Motor, according to machine model and work, there are AC motor and DC motor two kinds to our rubber extruding machine.

Our extruder machine adopts copper wire motor, which have good conductivity, low resistivity, and can achieve larger output power at smaller currents, thereby reducing electrical energy loss. Good corrosion resistance.

Copper wire motors are less prone to rusting and have a longer service life.

Excellent reliability. The connection points and joints of copper wire motors are easy to solder and connect, thus having higher reliability.

More durable.

The durability of copper wire motors is better than that of aluminum wire motors, because aluminum wire has a higher resistance than copper wire and generates higher heat during use, which can easily burn out the motor.

More energy-efficient, copper wire motors have a smaller resistance and lower heat generation, making them more energy-efficient.

More silent, copper wire motors used in our rubber vulcanizing press machine have less noise because aluminum wire motors have a noise level approximately 7 decibels higher than copper wire motors.

Mold, good parts makes good machine, but it also need a good design. We are just the maker which can provide you a perfect proposal according to your detail work needs.

Drawing just for Reference, if you want us make extruding mold for you, please send us your drawings or samples.

Normal Models (Pin Barrel Vacuum Cold Feed Rubber Extruder) for Choice:

| MODEL | XJP-45 | XJP-60 | XJP-75 | XJP-90 | XJP-120 | XJP-150 | XJP-200 | XJP-250 | |

| Screw Diameter(mm) | 45 | 60 | 75 | 90 | 120 | 150 | 200 | 250 | |

| L/D ratio | 8-12 | 8-12 | 8-14 | 12-16 | 12-16 | 12-16 | 12-16 | 12-18 | |

| Screw Rotation Speed(RPM) | ~70 | ~80 | 60 | ~60 (55) | ~50 | ~45 | ~33 | ~26 | |

| Production capacity(kg/h) | 30-50 | 80~160 | 100-200 | 250~450 | 600~1000 | 1000-2000 | 1600-2800 | 2800-3500 | |

| Main motor power(KW) | 12~22 | 18.5~22 | 37~45 | 45~75 | 75~110 | 160~250 | 220~355 | 355~450 | |

| Overall Dimension(mm) | L | 2,165 | 2,200 | 2,300 | 3,360 | 3,750 | 5,200 | 7,150 | 8,500 |

| W | 1,100 | 1,310 | 1,150 | 1,150 | 1,600 | 1,650 | 1,950 | 2,450 | |

| H | 1,600 | 1,400 | 1,600 | 1,450 | 1,550 | 1,600 | 2,300 | 2,600 | |

| Total Weight (kg) | 1,200 | 1,800 | 2,100 | 3,000 | 4,200 | 5,350 | 9,800 | 15,000 | |

The equipment models and production processes used in the production of different rubber products are also different. Some rubber products require vacuum pumping during production, while others require the use of pin type rubber extruders during production. In addition, some products belong to single extrusion products, while others require the use of composite rubber extruders for extrusion production. The molding equipment and auxiliary equipment used in the production of different rubber products need to be selected based on the actual needs of the products.

Extruded Rubber Products for reference, just contact and tell us your work needs, we can make a perfect proposal for you with a most reasonable price.

Attend Exhibition:

Loading Container:

Just contact and tell us your work needs, we'll provide you a suitable proposal, high quality rubber extruder with most reasonable price.

Comments: