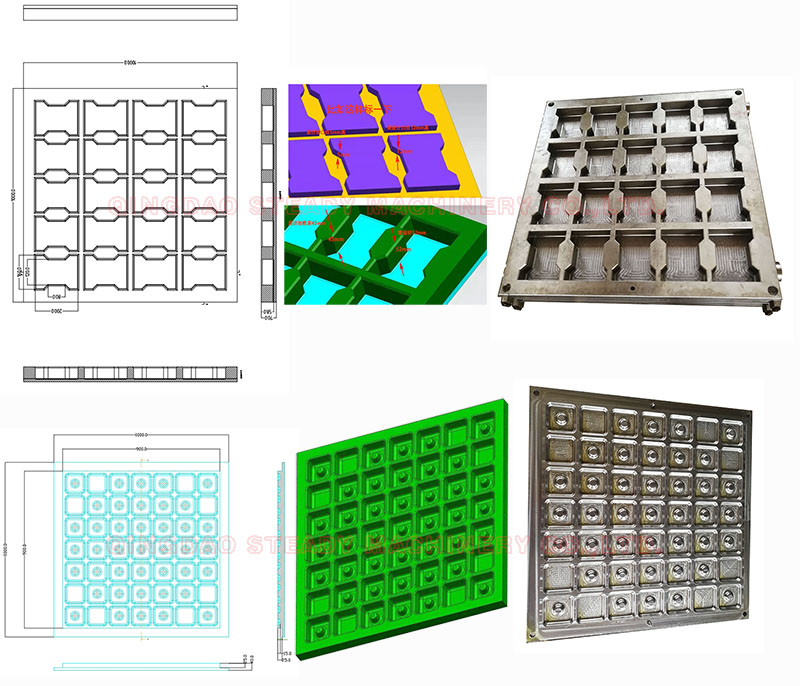

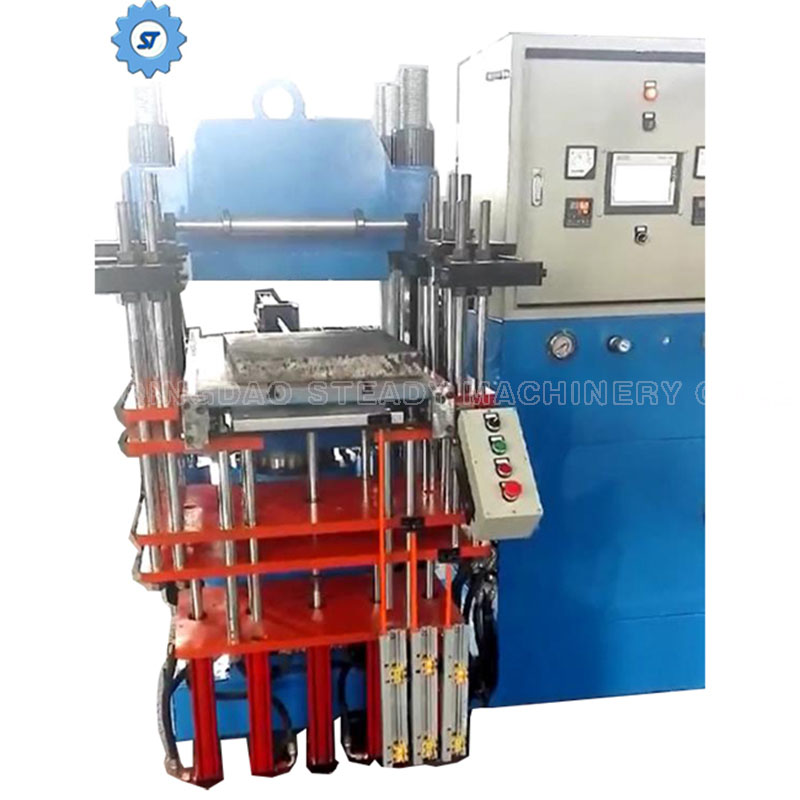

Our hydraulic vulcanizing compression molding press machine is a high-performance rubber vulcanization equipment designed for precision manufacturing and

some type of it is used in industrial belt splicing applications.

This advanced machine combines hydraulic pressure with accurate temperature control to ensure uniform heat distribution and strong, durable bonding during the vulcanization process.

It is widely used in the production of rubber sheets, conveyor belt joints, rubber components, and molded parts across industries such as mining, transportation, and heavy machinery.

Built with a robust steel frame and equipped with a digital temperature controller, this vulcanizing press machine ensures stable operation even under high-pressure conditions.

Its efficient heating system and adjustable pressure settings make it ideal for processing various rubber thicknesses and sizes.

Whether you're producing rubber products or repairing conveyor belts on-site, this machine offers reliable performance, easy operation, and long service life.

Comments: