A frame type rubber vulcanizer, also known as a frame type rubber curing press or rubber vulcanizing press, is a specialized machine used in the rubber industry for the curing or vulcanization of rubber products.

It applies heat and pressure to the rubber material, allowing it to undergo chemical reactions and transform into a durable, elastic, and stable rubber product.

Here are the key features and components of a frame type rubber vulcanizer:

1. Frame Structure: The machine consists of a sturdy frame that provides support and stability to the entire vulcanizer.

The frame is typically made of steel or other high-strength materials to withstand the high pressure and heat during the curing process.

2. Platens: The machine has two platens, an upper platen and a lower platen, which are mounted on the frame.

These platens are usually made of heat-resistant materials such as steel and are designed to provide uniform heating and pressure distribution across the rubber material during vulcanization.

3. Hydraulic System: The machine utilizes hydraulic power to generate and control the pressure applied to the rubber material during the curing process.

It includes hydraulic cylinders, pumps, valves, and pressure gauges to regulate and maintain the desired pressure levels.

The hydraulic system is responsible for controlling the pressing force and ensuring even distribution across the platens.

4. Heating System: The machine incorporates a heating system to raise the temperature of the platens and transfer heat to the rubber material.

The heating system may use electric heaters, steam, hot oil, or other heating mediums, depending on the specific design of the machine.

The heating system is responsible for achieving and maintaining the desired vulcanization temperature.

5. Temperature and Time Control: The machine is equipped with temperature and time control systems to ensure precise control over the vulcanization process.

These systems allow operators to set and monitor the desired curing temperature and duration, ensuring optimal curing conditions for different types of rubber compounds.

6. Safety Features: Frame type rubber vulcanizers are equipped with various safety features to protect operators and prevent accidents.

These features may include emergency stop buttons, safety guards, pressure relief valves, and interlock systems to ensure safe operation.

Frame type rubber vulcanizers come in different sizes and configurations to accommodate various production requirements and rubber product dimensions.

They are widely used in the manufacturing of rubber products such as tires, conveyor belts, rubber sheets, rubber seals, and other molded rubber components.

The vulcanization process performed by these machines enhances the physical and mechanical properties of the rubber, providing durability, elasticity, and resistance to various environmental factors.

Common Models, if you need other models or have other special technical requirements on size, pressure, working layer number, please just contact us.

| Model | 300*300*2 | 350*350*2 | 400*400*2 | 500*500*2 | 600*600*2 | 750*850*2 | 600*600*2 |

| Nominal Mold Clamping Force(MN) | 0.25 | 0.25 | 0.5 | 0.8 | 1 | 1.6 | 2 |

| Heating Platen Size(mm) | 300*300 | 350*350 | 400*400 | 500*500 | 600*600 | 750*850 | 600*600 |

| Working Layer | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Piston Diameter(mm) | ø150 | ø150 | ø200 | ø250 | ø300 | ø360 | ø400 |

| Piston Stroke(mm) | 250 | 250 | 250 | 250 | 250 | 500 | 300 |

| Daylight/ Platen Spacing(mm) | 125 | 125 | 125 | 125 | 125 | 250 | 150 |

| Unit Area Pressure(Mpa) | 2.78 | 2.1 | 3.1 | 3.2 | 2.78 | 2.5 | 5.6 |

| Main Motor Power(KW) | 2 | 2.2 | 2.2 | 2.2 | 2.2 | 3.0 | 3.0 |

| Dimension(L×W×H)mm | 1500*400*1350 | 1500*400*1350 | 1800*500*1600 | 1800*550*1700 | 2000*700*1700 | 2000*1000*1900 | 2550*960*2100 |

| Weight(KG) | 950 | 1000 | 1500 | 2000 | 2600 | 4300 | 5000 |

| Mold Closing Speed(mm/s) | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 |

| Mold Opening Speed(mm/s) | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 |

Detail Images of frame type rubber vulcanizer machine:

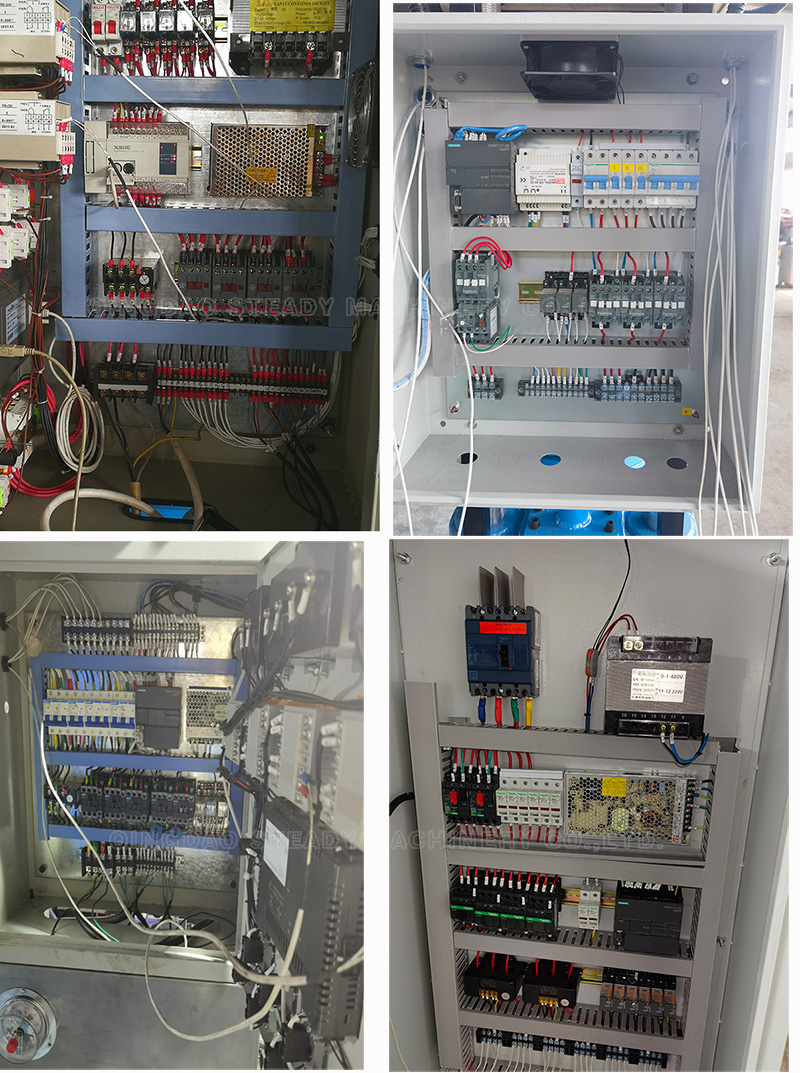

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put a few for your reference.

Control Box

Mainly there are two kinds of electronics for choice. 1. China domestic made: CHNT or Delixi

2. imported international famous brand: Siemens, Schneider, Omron, Abb, etc.

Oil Cylinder and Piston of my company's rubber vulcanizing press machine:

Oil cylinder adopts QT500-7 ductile iron, called FCD50 in Japan, and for some huge size machines, we adopt cast steel oil cylinder;

piston adopts chilled hard alloy cast iron; seal adopt imported international quality sealing ring and dustproof ring, to ensure long working life.

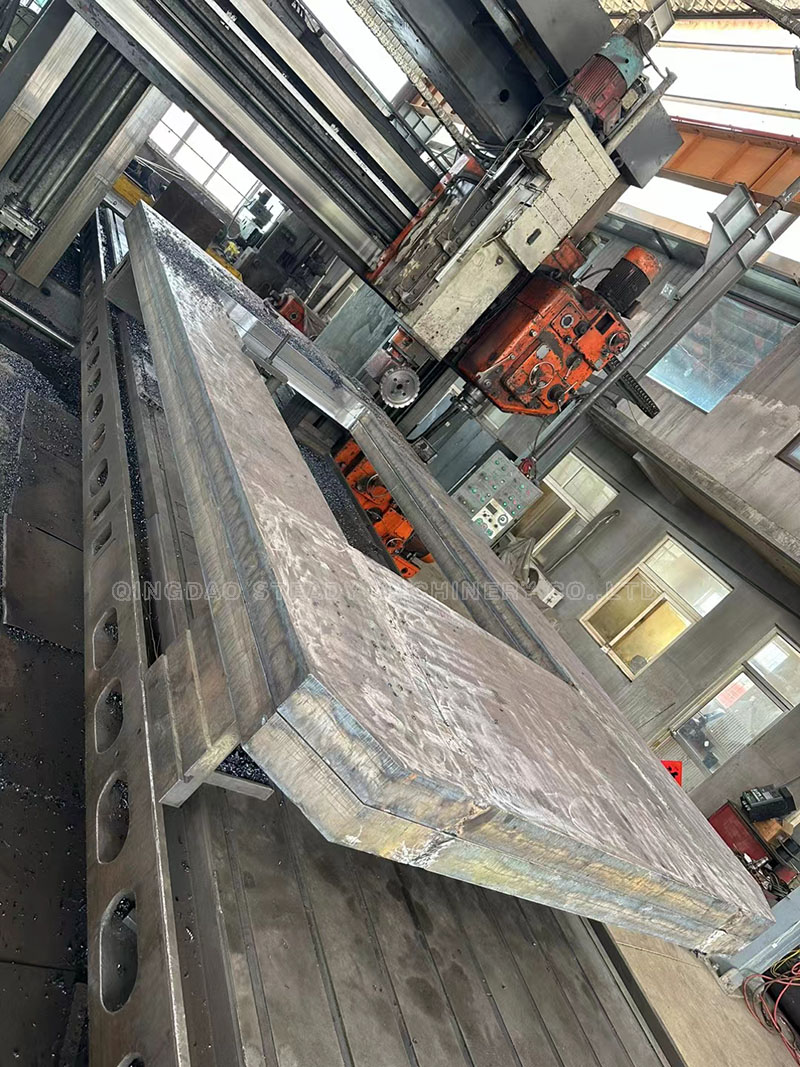

The up seat and middle platform, we normally adopts weld structure to easily meet customer's size requirement.

But after the welding, we did do heat treatment to remove stress, thus ensures our machine parts can keep it's shape, won't deformation.

Heat treatment after welding

Frame milling work,

Frame

Huge Size Maching Machine, which ensures we can make huge size rubber vulcanizer machine

The piston of our rubber vulcanizing press machine adopts cold/chilled hard cast iron

1、Basic knowledge of cold hard cast iron

Cold hard cast iron is a casting alloy material that is based on elements such as iron, carbon, and silicon. By adding alloying elements such as chromium, molybdenum, and vanadium, and through casting and heat treatment processes, it achieves excellent hardness and wear resistance. Its hardness and wear resistance far exceed those of ordinary cast iron and gray iron, and it also has high strength and toughness, which has been widely used in the industrial field.

2、 The Hardness Characteristics of Cold Hardened Cast Iron

The hardness of cold hard cast iron is mainly achieved through heat treatment and chemical composition control. Compared to other casting materials, its hardness is extremely high, usually between 60-65 HRC, while the hardness of steel is only between 50-55 HRC.

3、 The manufacturing process of cold hard cast iron

The manufacturing process of cold hard cast iron mainly includes two processes: casting and heat treatment. During the casting process, control the chemical composition ratio in the as cast state to ensure the ratio of ferrite and pearlite; During the heat treatment process, magnesium spheroidization is subjected to high-temperature treatment, followed by quenching and tempering to obtain excellent hardness and toughness.

4、 The Application Prospects of Cold Hardened Cast Iron

Due to its excellent properties such as hardness and wear resistance, cold cast iron is widely used in manufacturing mechanical parts and tools under high load and high wear working environments. In the field of engineering machinery, some key components have also begun to use cold cast iron materials to improve the service life and safety performance of machinery.

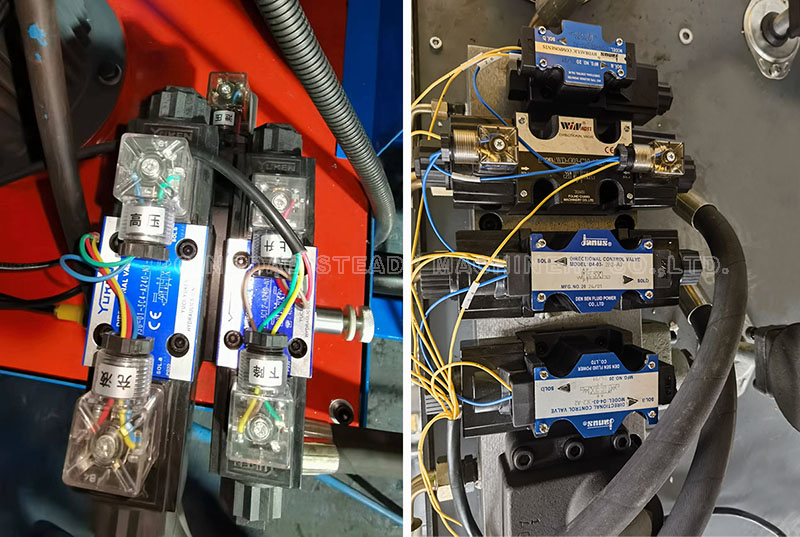

Valves

Qingdao Steady Machinery Co.,Ltd. adopts international famous brand solenoid valves for it's rubber vulcanizing press machine.

Which works accurately and has a long service life.

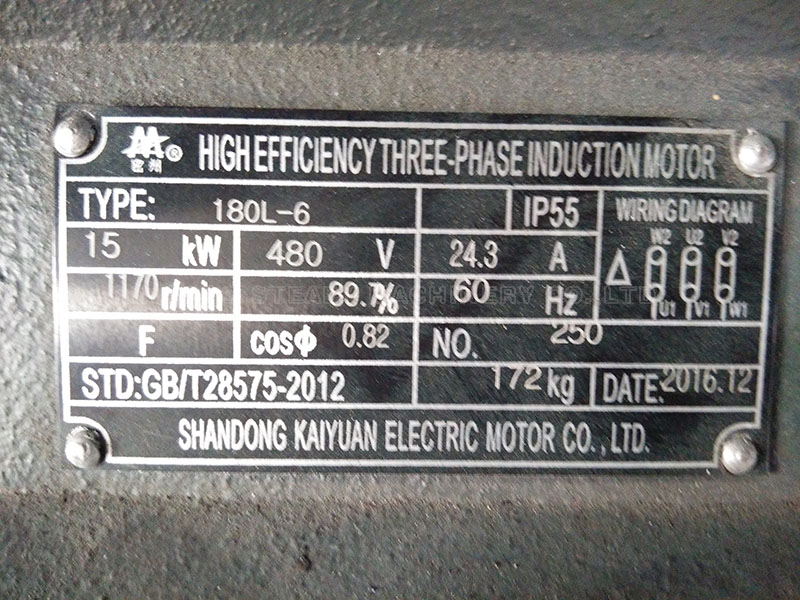

Motor

We adopts China famous brand motor or imported brand motor if customers' have special demand.

The brand of motor we choose uses high-quality copper wire for coils and wiring, which has excellent conductivity.

Copper wire motors have good conductivity, low resistivity, and can achieve larger output power at smaller currents, thereby reducing electrical energy loss. Good corrosion resistance.

Copper wire motors are less prone to rusting and have a longer service life.

Excellent reliability. The connection points and joints of copper wire motors are easy to solder and connect, thus having higher reliability.

More durable.

The durability of copper wire motors is better than that of aluminum wire motors, because aluminum wire has a higher resistance than copper wire and generates higher heat during use, which can easily burn out the motor.

More energy-efficient, copper wire motors have a smaller resistance and lower heat generation, making them more energy-efficient.

More silent, copper wire motors used in our rubber vulcanizing press machine have less noise because aluminum wire motors have a noise level approximately 7 decibels higher than copper wire motors.

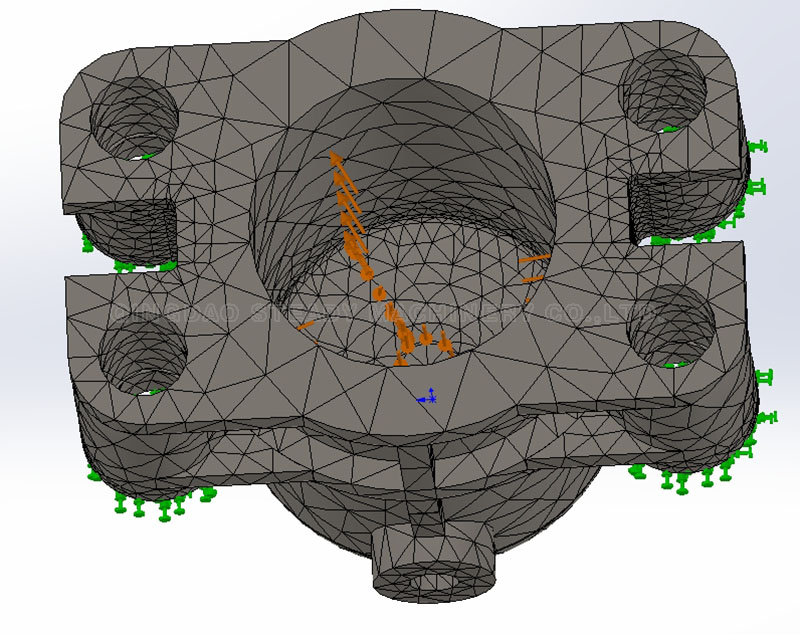

Good parts ensures good machine quality, but it need plus a good design.

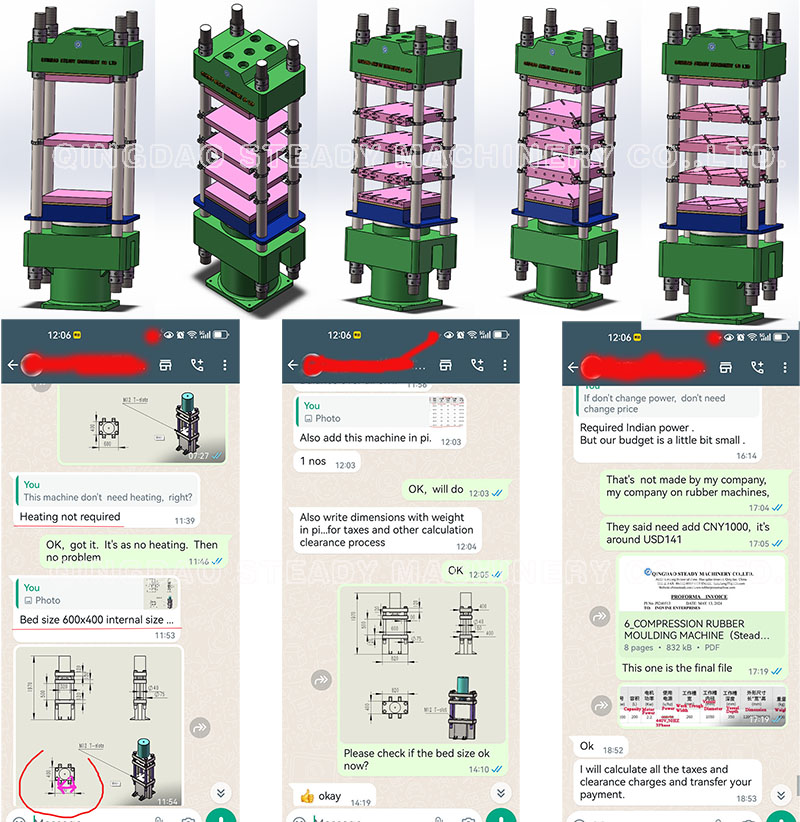

Our engineer service team provide in time design according to customers work needs or special requirements:

FEA( Finite Element Analysis), to ensure our machine parts is strong enough.

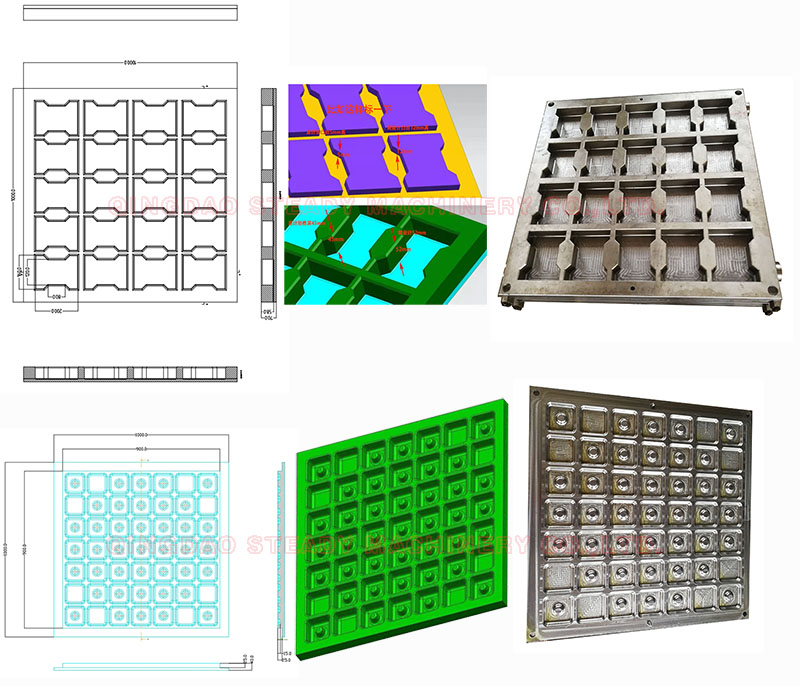

Various kinds rubber products can be made by rubber vulcanizing press machine

Rubber Molds

We can also make molds according to clients' samples or drawings:

Just contact us

Comments: