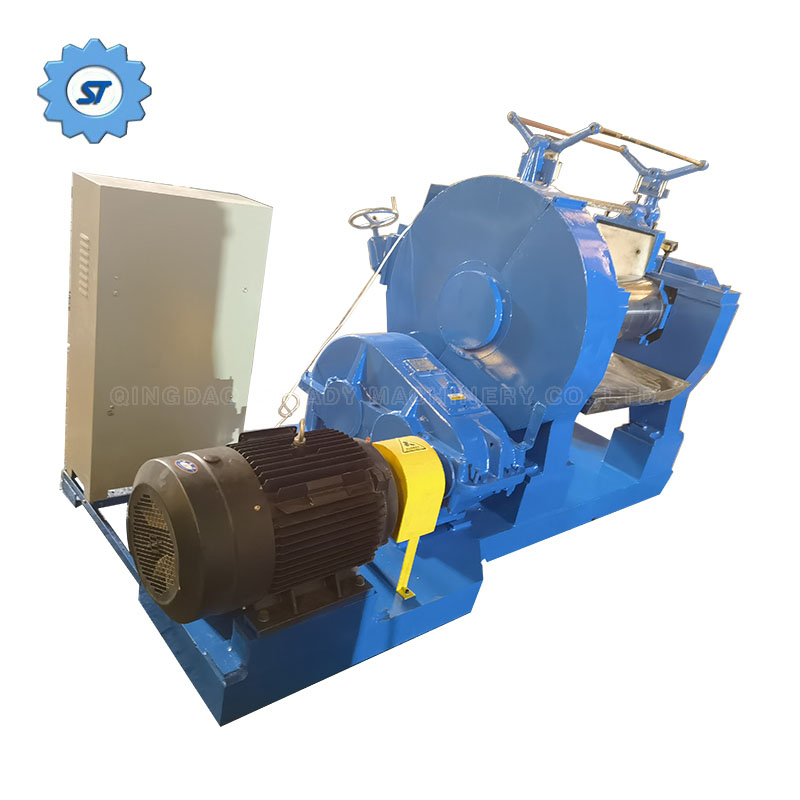

Rubber two-roll open mixing mill, also known as an open mill, is a common piece of equipment used in the rubber industry for the mixing and processing of rubber compounds. It is widely used in the production of rubber sheets, rubber strips, and various rubber products.

The main purpose of a rubber two-roll open mixing mill is to blend and homogenize rubber materials and additives to create a uniform compound. The mixing process involves combining raw rubber, fillers, plasticizers, accelerators, and other ingredients on the open mill to achieve the desired properties and characteristics of the rubber compound.

The construction of a rubber two-roll open mixing mill consists of two horizontally arranged, counter-rotating rolls made of high-quality, heat-treated steel. The rolls have different speeds and friction ratios, allowing for efficient mixing and dispersion of the rubber materials.

The rubber compounds are introduced into the nip between the two rolls, and as the rolls rotate, the material is sheared, stretched, and folded. This mechanical action results in the breakdown of rubber lumps, dispersion of additives, and uniform distribution of the ingredients throughout the compound.

The open mill is equipped with adjustable roll gaps to control the thickness of the rubber sheet being produced. Cooling systems, such as water or air circulation, may be incorporated to maintain the temperature of the rolls and prevent overheating during the mixing process.

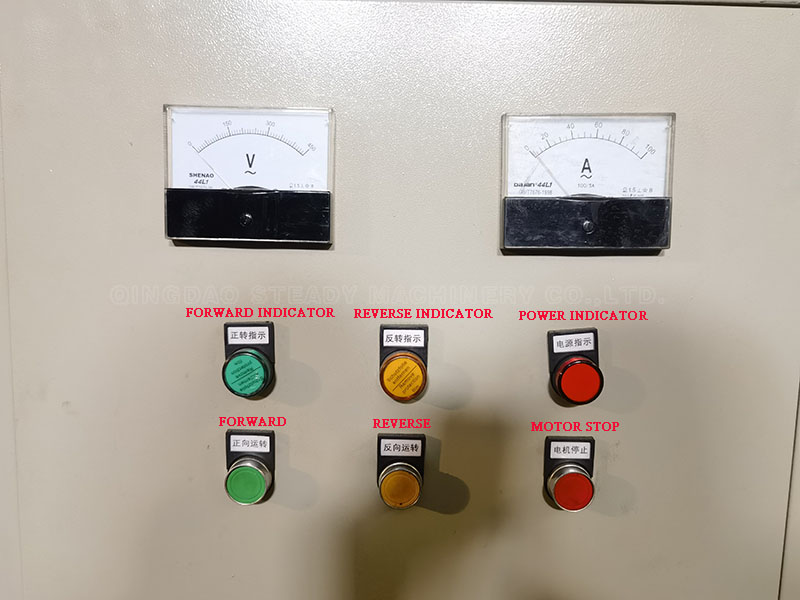

The control panel of the open mill allows for adjustments of the roll speeds, roll gaps, and other parameters to achieve the desired mixing conditions and optimize the mixing efficiency.

Throughout the mixing process, the rubber compound is continuously removed from the mill rolls using a cutting device or mill knife. The compound can then be further processed or shaped into the desired form, such as sheets or strips, or fed into downstream equipment for further manufacturing.

The rubber two-roll open mixing mill is an essential machine in rubber processing, as it provides thorough mixing, dispersion, and blending of rubber compounds. It helps to improve the consistency, quality, and performance of rubber materials, ensuring the production of high-quality rubber products.

I hope this provides a clear understanding of the rubber two-roll open mixing mill. If you have any further questions, feel free to ask.

Common Models, if you need other models or have other special technical requirements on size, pressure, working layer number, please just contact us.

| Model | XK-150 | XK-250 | XK-300 | XK-360 | X(S)K-400 | X(S)K-450 | X(S)K-560 | X(S)K-710 |

| Roll Diameter(mm) | ø150 | ø250 | ø300 | ø360 | ø400 | ø450 | ø560 | ø710 |

| Roller Working Length(mm) | 280 | 620 | 750 | 900 | 1000 | 1200 | 1530 | 2300 |

| Front Roll Linear Speed(m/min) | 8 | 15.1 | 15.1 | 16.25 | 18.65 | 24.5 | 27.7 | 26.6 |

| Speed Ratio | 1:1.4 | 1:1.17 | 1:1.27 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.12 | 1:1.09 |

| Max. Nip(mm) | 10 | 10 | 10 | 10 | 15 | 15 | 15 | 15 |

| One Batch Capacity(kg) | 1-2 | 10-15 | 15-20 | 20-25 | 18-35 | 25-50 | 50-65 | 350 |

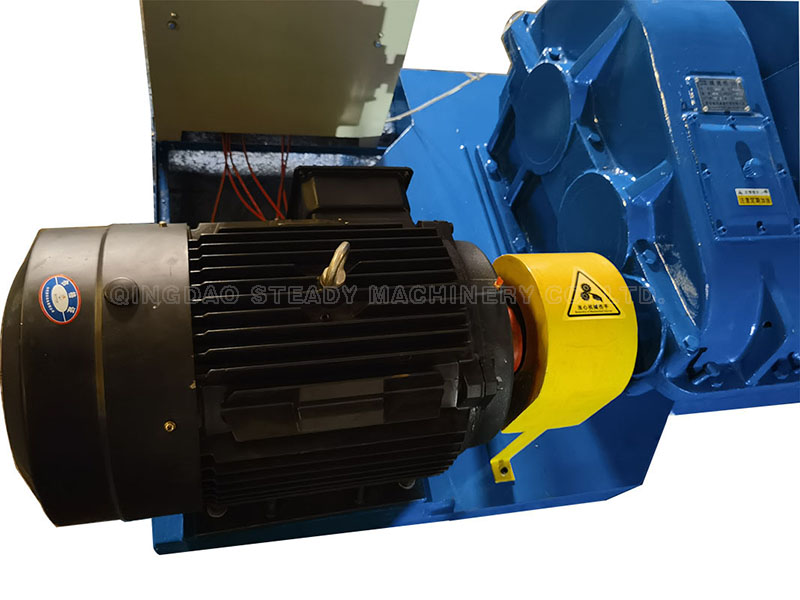

| Driving Motor Power(KW) | 7.5 | 18.5 | 22 | 30 | 37 | 55 | 95 | 280 |

| Dimension[L×W×H](mm) | 1080*796* 1450 | 3400*1350* 1500 | 3580*1550* 1695 | 3490*1780* 1740 | 4250*1850* 1870 | 5200*2280* 1770 | 6120*2380* 2000 | 7000*2500* 2300 |

| Weight(kg) | 1100 | 3500 | 5205 | 5670 | 7600 | 13000 | 22000 | 35000 |

Detail Images of Rubber two roll open mixing mill:

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put a few for your reference.

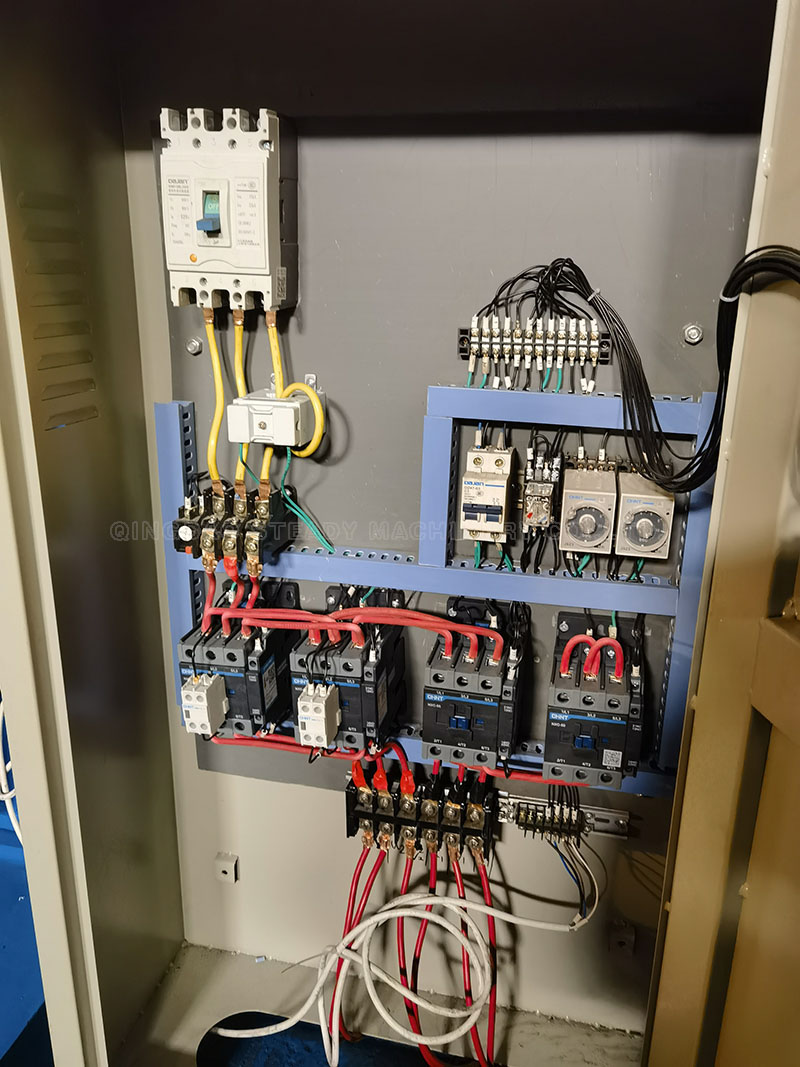

Control Box

Normally it's CHNT brand. If customers want other band, just tell us.

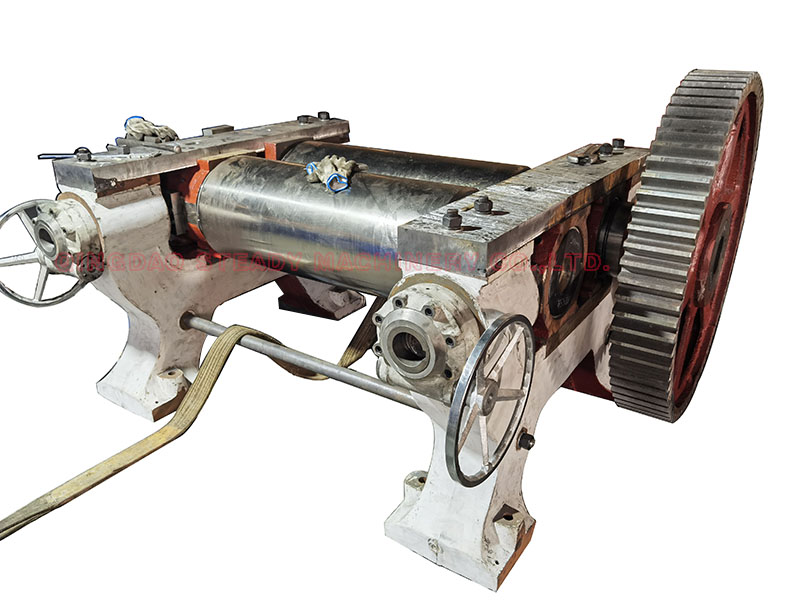

Rollers, our rubber open mixing mill machine adopts chilled hard cast iron raw material:

Rubber mixer is one of the important equipment used in the rubber processing industry for mixing, plasticization, dispersion and other processes. It mainly consists of two relatively rotating drums, which achieve the purpose

of mixing by squeezing and shearing the rubber material through these two drums.

So the roller is a very important component of the rubber mixer:

1. * * Cold hard cast iron * *: This is a material description that refers to cast iron materials that have undergone special treatment. Cold hard cast iron (also known as cold hard iron or wear-resistant cast iron) has high hardness

and good wear resistance, making it an ideal material for manufacturing open mill drums. Because during the refining process, the drum needs to withstand continuous wear and compression of rubber materials, the use of

cold hard cast iron can effectively extend the service life of the drum and reduce maintenance costs.

2. Mirror roller: This is a description of the surface condition of the roller. Mirror surface means that the surface of the drum has been finely processed and polished, achieving a very smooth surface effect similar to a mirror.

This approach has the following benefits:

-* * Reduce adhesion * *: The mirror smooth surface of the drum can effectively reduce the adhesion of rubber materials during the mixing process, which helps to improve production efficiency and product quality.

-* * Uniform mixing * *: A smoother surface can make the rubber material more evenly distributed between the rollers, which is conducive to material dispersion and mixing during the mixing process, and improves the mixing

effect.

-Easy to clean: The mirror roller is easier to clean after use, maintaining the hygiene conditions of the equipment, which is particularly important for the production of certain rubber products that have strict requirements for

cleanliness.

In summary, a rubber open mill equipped with a cold hard cast iron mirror roller combines the high wear resistance of the material and the high smoothness of the surface, aiming to improve production efficiency, ensure mixing

quality, and extend the service life of the equipment. It is one of the high-end configurations in the rubber processing industry.

Reduce: We adopt cylindrical gear reducer for bull/big gear type rubber open mixing mill machine

The cylindrical gear reducer has the following main advantages:

1. * * Simple structure * *: The design of cylindrical gear reducers is relatively direct, easy to understand and maintain, making it the foundation for widespread application.

2. * * Cost effectiveness * *: Due to the relatively simple design and manufacturing process, the production cost of cylindrical gear reducers is lower, making them cost-effective for users.

3. * * High transmission efficiency * *: The transmission efficiency of this type of reducer can reach over 95%, which means that most of the input power can be effectively converted into output torque, reducing energy loss.

4. Smooth torque transmission: The contact area of cylindrical gears is large, making power transmission more uniform and stable, suitable for situations that require stable torque output.

5. * * Wide applicability * *: Suitable for various industrial environments, including machine tools, conveying equipment, mixing equipment, packaging machinery, as well as mining, metallurgy and other industries, and can

adapt to different speed and torque requirements.

6. * * Modular and Flexible * *: Many cylindrical gear reducers offer diverse installation options (such as horizontal and vertical), multiple assembly types, and a variety of standardized accessories for easy design and customization.

7. * * High reliability and failure safety * *: Using high-quality materials and strict manufacturing standards to ensure long-term stable operation and high safety.

8. * * Easy to install and maintain * *: Standard interfaces and components simplify the installation process, while reducing maintenance requirements, downtime, and maintenance costs.

These advantages make cylindrical gear reducers an indispensable power transmission solution in many industrial applications.

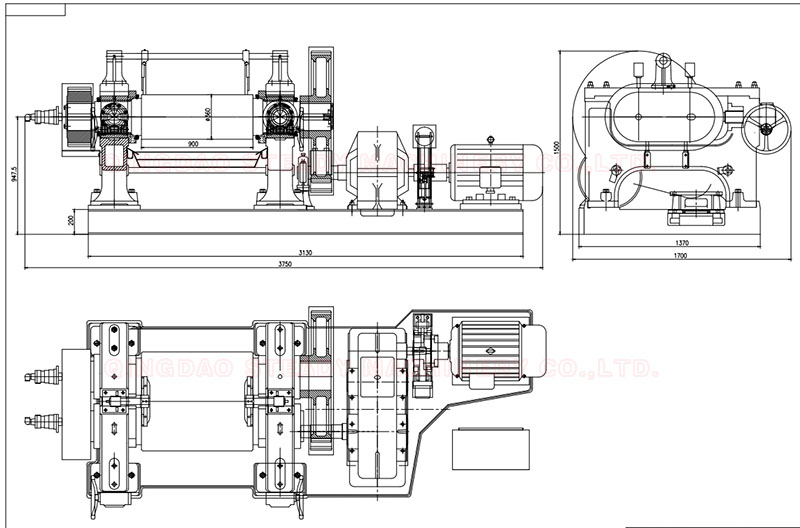

One of the drawings just for reference

Machine in Building

In rubber sheet press working.

NOTE: the machine has auto reverse rotation function, when emergency condition happen( suppose some thing or operator's hand roll in the gap of the two rollers, just pull or push the overhead bar,

the machine will immediately rotate reversely, for protection purpose.

Loding Container Export of various model/type rubber open mixing mill

Just contact us

Comments: