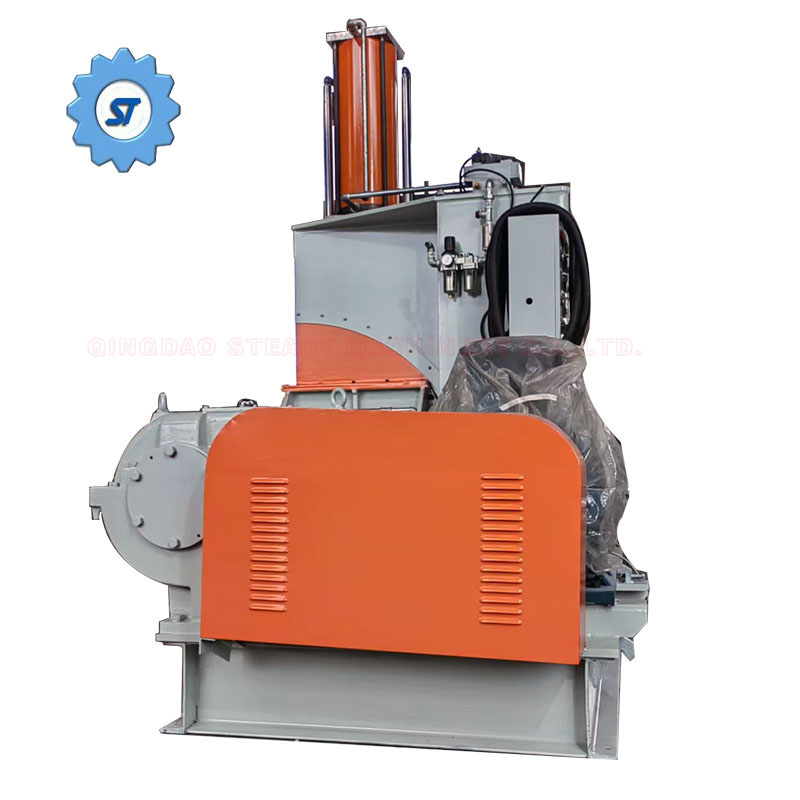

A rubber kneader is a machine used in the rubber industry to knead and mix rubber compounds. It is designed to efficiently blend and homogenize various ingredients, such as rubber, fillers, chemicals, and additives, to produce a uniform and consistent rubber compound. The kneader typically consists of a mixing chamber equipped with rotating blades that continuously knead and mix the rubber materials. This process helps to improve the dispersion of fillers and other additives, ensuring the desired properties of the final rubber product. Rubber kneaders are widely used in the production of various rubber products, including tires, rubber sheets, and rubber components.

rubber banbury kneading machine

A rubber Banbury kneading machine, also known as a Banbury mixer, is a type of industrial machine used in the rubber and plastic industries for mixing and kneading rubber compounds. It is named after the town of Banbury in England, where it was first invented.

The Banbury mixer consists of a large, rectangular mixing chamber that houses two counter-rotating blades. The blades are shaped like a figure-eight and have intermeshing teeth. The rubber material, along with other additives and fillers, is fed into the mixing chamber, and the blades continuously mix, shear, and knead the materials together.

The mixing action of the Banbury mixer helps to break down the rubber compounds and achieve a uniform and homogenous mixture. It also facilitates the dispersion of fillers, additives, and other ingredients, ensuring that they are evenly distributed throughout the rubber compound.

Banbury kneading machines are known for their high mixing efficiency and the ability to process a wide range of rubber compounds. They are widely used in the rubber industry for the production of tires, conveyor belts, rubber sheets, footwear, and various rubber products.

Common Models, if you need other models or have other special requirements, please just contact us.

Model | X(S)N-1×12~58 | X(S)N-3×32(6~60) | X(S)N-10×32 | X(S)N-20×30 | X(S)N-35×30 | X(S)N-55×30 | X(S)N-75×30 | X(S)N-110×30 | X(S)N-150×30 | X(S)N-200×30 | X(S)N-300×30 |

Total volume of kneading chamber(L) | 3 | 8 | 25 | 45 | 75 | 125 | 180 | 250 | 325 | 440 | 700 |

Working volume of mixing chamber (L) | 1 | 3 | 10 | 20 | 35 | 55 | 75 | 110 | 150 | 200 | 300 |

Driving motor power(KW) | 4 | 5.5 | 15 | 30 | 55 | 75 | 110 | 185 | 220 | 280 | 280/400 |

Overturn motor power(KW) | manual | 0.55 | 1.1 | 1.5 | 2.2 | 3.0 | 4.0 | 5.5 | 5.5 | 7.5 | 7.5 |

Overturn angle(°) | ≤140 | 135 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

Rotation speed of rotor(front/back)r/min | 12~58 | 6-60 32/24.5 | 32/23.5 | 30/25 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 |

Pressure of compressed air(Mpa) | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

Flow rate of compressed air(m³/min) | ≥0.3 | ≥0.3 | ≥0.5 | ≥0.7 | ≥0.9 | ≥1.0 | ≥1.0 | ≥1.5 | ≥2.0 | ≥2.0 | ≥2.0 |

Pressure of cooing water(Mpa) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

Pressure of heated steam(Mpa) | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 |

Overall dimension(L*W*H)(mm) | 1400*760*1914 | 1660*960*1750 | 2580*1300*2280 | 2630*1520*2550 | 3200*1900*2495 | 3360*1950*3050 | 3760*2143*3135 | 4075*2712*3580 | 4200*3300*4000 | 4520*3400*4215 | 5070*3500*4600 |

Weight(KG) | 800 | 2000 | 3300 | 4500 | 6500 | 7800 | 10500 | 14500 | 19500 | 22500 | 27500 |

Detail Images of rubber kneader machine:

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put a few for your reference.

Control Box

Mainly use CHNT brand electronics

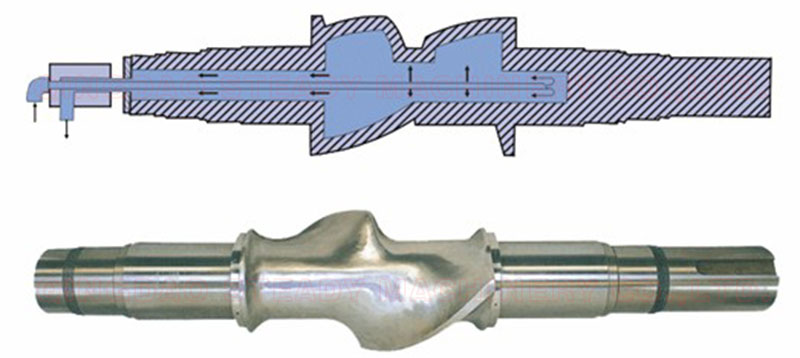

rotors of my company's rubber vulcanizing press machine:

1. The banbury mixer is an internal mixer with intermeshing rotors. The wings and the working surfaces of the rolls, the internal surfaces of the mixing chamber, and the working surfaces of the pressing ram device and the discharge device are all put on with wearable hard alloy by built-up welding method, which are durable and corrosion proof and have a longer life of service.

2. The shape of the rotors is cylindrical. As it has big wings with large cooling area, it can improve the quality of the mixing rubber and thus increase the productive efficiency. It may shorten two mixing periods into one.

Mixing Chamber

Jacket construction is adopted in parts that surfaces contact with materials to achieve excellent water-cooling or steam heating effect and fit in with the needs of plastics and rubber processing technology.

Ruducer, famous brand hard tooth reducer adopted

The hard tooth reducer has the following significant advantages:

1. * * High hardness and high precision * *: The gears of the hard tooth surface reducer undergo heat treatment processes such as carburization and quenching, resulting in a tooth surface hardness of HRC45 or above, some

of which can reach 54-62HRC. This not only improves the wear resistance of the gears, but also ensures high transmission accuracy.

2. * * Enhanced bearing capacity * *: Due to the high hardness of the tooth surface, the hard tooth surface reducer can withstand greater loads and torques, making it suitable for heavy-duty and harsh working conditions,

such as cranes, mining equipment, large cement mixers, etc.

3. * * Improve transmission efficiency * *: The transmission efficiency of hard tooth surface reducers is usually higher than that of soft tooth surface reducers, with a maximum of over 95%, which helps to save energy and

reduce consumption.

4. Compact and Lightweight Design: The optimized design makes the gearbox smaller in size and lighter in weight, while maintaining high load-bearing capacity, which is beneficial for the overall design and layout of the

equipment.

5. Low noise and smooth operation: The excellent machining and high-precision assembly of hard tooth surface gears ensure low noise and stability during the transmission process, improving the working environment.

6. * * Long lifespan and high reliability * *: The wear resistance and high toughness of the hard tooth surface extend the service life of the reducer, reduce maintenance needs, and improve the overall operational reliability of

the equipment.

7. * * Wide applicability * *: The hard tooth reducer is suitable for various industries, including metallurgy, mining, lifting, transportation, cement, construction, chemical, textile, printing and dyeing, medicine, etc., demonstrating

its wide applicability and universality.

8. * * Low maintenance cost * *: Due to its durability and long lifespan, the hard tooth reducer reduces the maintenance and replacement costs for users.

9. * * Efficient heat dissipation * *: Most hard toothed reducers are designed with effective natural cooling or auxiliary cooling systems to ensure normal operating temperatures are maintained even during high load operations.

These advantages make the hard tooth reducer an ideal choice for situations that require high efficiency, high torque transmission, and long-term stable operation.

End seal, brass sealing ring

The brass sealing ring in the rubber mixer is one of the key components, mainly used to ensure that the mixer maintains good sealing performance during operation, prevent material leakage, and maintain the working pressure

and temperature inside the equipment.

The brass sealing ring has the following advantages due to its material characteristics:

1. * * Material Uniformity * *: The brass sealing ring is made of a single material, which means that its performance in all parts is uniform and consistent. Compared to the combination sealing ring, it reduces the possibility

of leakage

and separation.

2. * * No electrochemical corrosion * *: Due to the same material of the entire sealing ring, there is no electrochemical corrosion problem caused by different metal contacts, which enhances its durability and service life.

3. * * Wear resistance * *: Especially the brass sealing ring made of tin bronze has excellent wear resistance and is suitable for use in high wear working environments such as rubber mixers.

4. * * High precision machining * *: Through CNC lathe precision machining, the brass sealing ring can achieve high manufacturing accuracy, ensuring good sealing effect and stable equipment operation.

5. * * Complete specifications * *: Manufacturers such as Dalian Chengfeng Rubber Machinery Co., Ltd. provide various specifications of brass sealing rings, suitable for different models of internal mixers, to meet the diverse

needs

of customers.

6. * * Design Optimization * *: The sealing system of modern mixers is constantly evolving, such as using advanced technologies such as hydraulic sealing and spring loaded rotor sealing. These designs require high-performance

sealing rings to achieve better sealing effects.

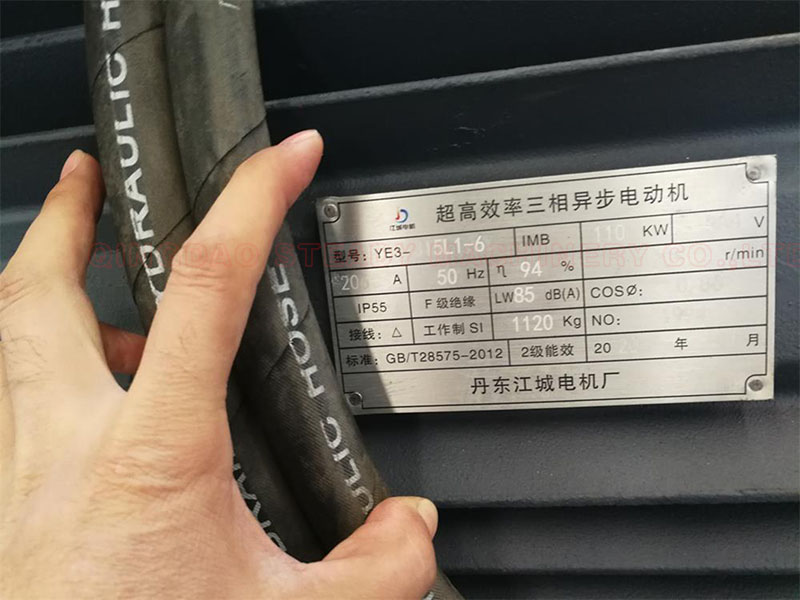

Motor

We adopts China famous brand pure copper wire motor adopted.

The brand of motor we choose uses high-quality copper wire for coils and wiring, which has excellent conductivity.

Copper wire motors have good conductivity, low resistivity, and can achieve larger output power at smaller currents, thereby reducing electrical energy loss. Good corrosion resistance.

Copper wire motors are less prone to rusting and have a longer service life.

Excellent reliability. The connection points and joints of copper wire motors are easy to solder and connect, thus having higher reliability.

More durable.

The durability of copper wire motors is better than that of aluminum wire motors, because aluminum wire has a higher resistance than copper wire and generates higher heat during use, which can easily burn out the motor.

More energy-efficient, copper wire motors have a smaller resistance and lower heat generation, making them more energy-efficient.

More silent, copper wire motors used in our rubber vulcanizing press machine have less noise because aluminum wire motors have a noise level approximately 7 decibels higher than copper wire motors.

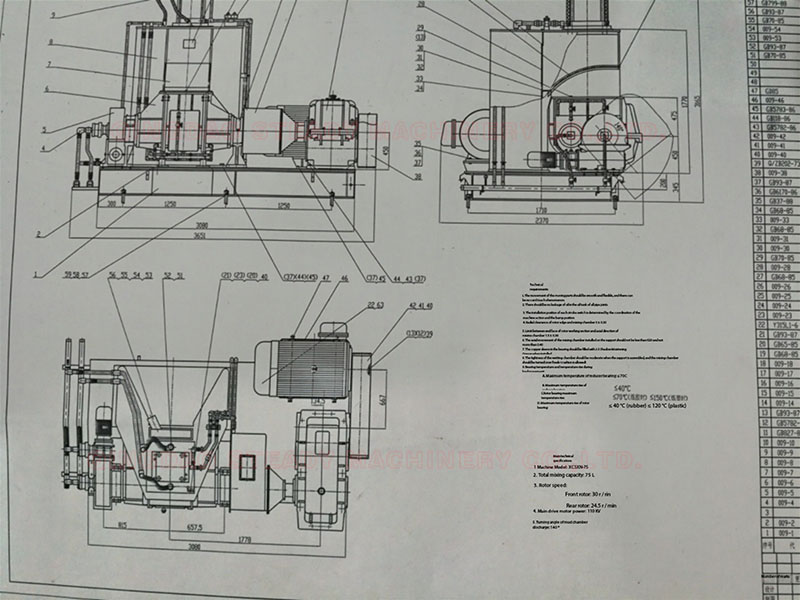

One of the drawings for just reference

Rubber kneader installation

Loading Container Export

Work in user's factory

Just contact us

Comments: