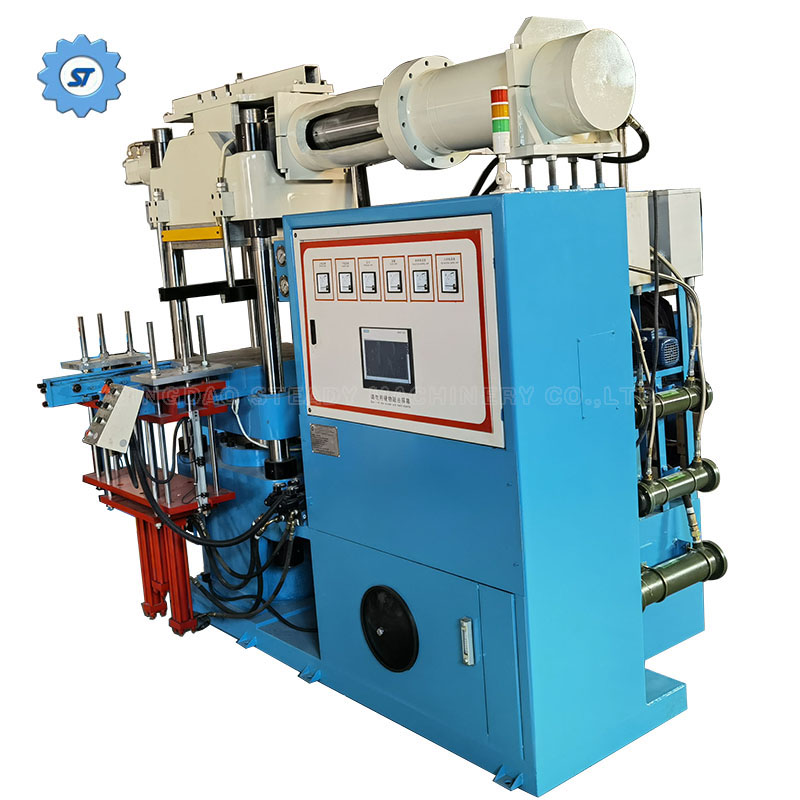

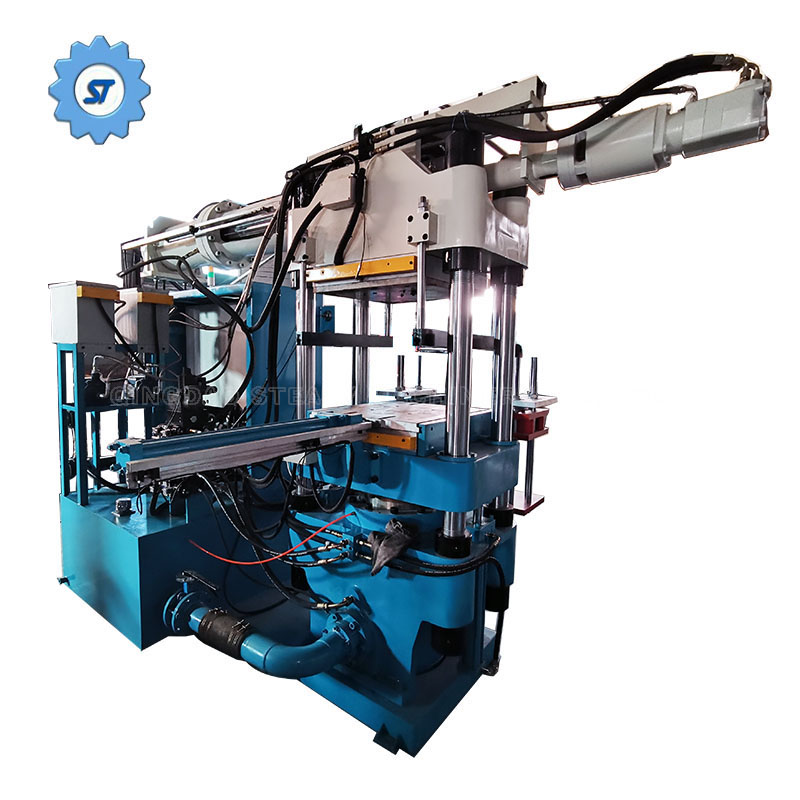

A rubber injection molding machine is a specialized machine used in the rubber industry for manufacturing rubber products through the process of injection molding.

It is commonly used for the production of various rubber components, such as seals, gaskets, O-rings, and automotive parts.

The rubber injection molding machine operates using the principle of injecting molten rubber material into a mold cavity under high pressure.

The machine typically consists of a screw or plunger mechanism that feeds the rubber material into the injection unit, where it is heated and melted.

The molten rubber is then injected into a closed mold cavity through a nozzle or sprue system.

Once the mold cavity is filled with the molten rubber, it is held under high pressure to ensure proper filling and curing of the rubber material.

The pressure is maintained until the rubber has solidified and achieved the desired shape and properties. The mold is then opened, and the finished rubber product is ejected from the machine.

Rubber injection molding machines offer advantages such as precise control over the injection process, high production efficiency, and the ability to produce complex shapes and intricate details.

They are widely used in industries such as automotive, electronics, medical, and consumer goods.

It is important to operate the rubber injection molding machine in accordance with safety guidelines to prevent accidents and injuries.

Regular maintenance and cleaning of the machine, as well as inspection of the mold, are necessary to ensure optimal performance and product quality.

Common Models, if you need other models or have other special technical requirements on size, pressure, working layer number, please just contact us.

| Model | RIM-100T | RIM-200T | RIM-300T | RIM-400T | RIM-800T |

| Screw Dia.(φmm) | 30 | 40 | 50 | 55 | 75 |

| Plasticizing capacity(cm3/min) | 500 | 800 | 1000 | 1500 | 2000 |

| Injection pressure (MPa) | 175 | 173 | 180 | 195 | 174 |

| Piston Dia. (φmm) | 70 | 80 | 95 | 95 | 95 |

| Injection Volume (cm3) | 1000 | 2000 | 3000 | 4000 | 10000 |

| Mode locking force (KN) | 1000 | 2000 | 3000 | 4000 | 8000 |

| Piston Stroke (mm) | 400 | 500 | 600 | 600 | 1000 |

| Hot plate spacing (mm) | 450 | 570 | 750 | 750 | 1400 |

| Min. mould thickness(mm) | 60 | 80 | 160 | 160 | 400 |

| Heating platen size(mm) | 450×450 | 540×580 | 700×600 | 800×700 | 1000×1000 |

| Electronic power(kW) | 12 | 12 | 18 | 18 | 48 |

| Working Pressure (MPa) | 20 | 20 | 20 | 20 | 17.7 |

| Motor Power(kW) | 7.5 | 11 | 15 | 15 | 37 |

| Installed power (KW) | 26 | 30 | 40 | 40 | 40 |

| Dimension (L×W×H)(m) | 3×1.9×3 | 3×2.3×4 | 3.4×2.3×4.4 | 3.6×2.8×4.8 | 5.8×2×6.7 |

| Total Weight(T) | 4 | 6 | 10 | 13 | 40 |

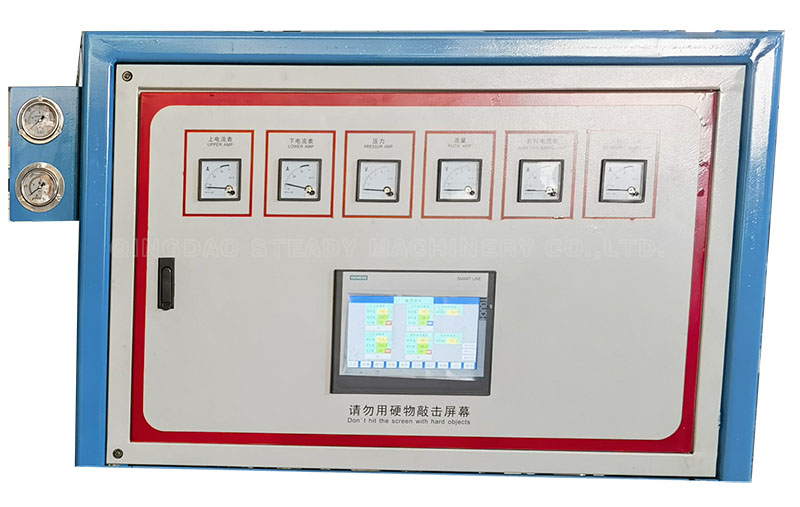

Detail Images of PLC control rubber vulcanizing press machine:

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put a few for your reference.

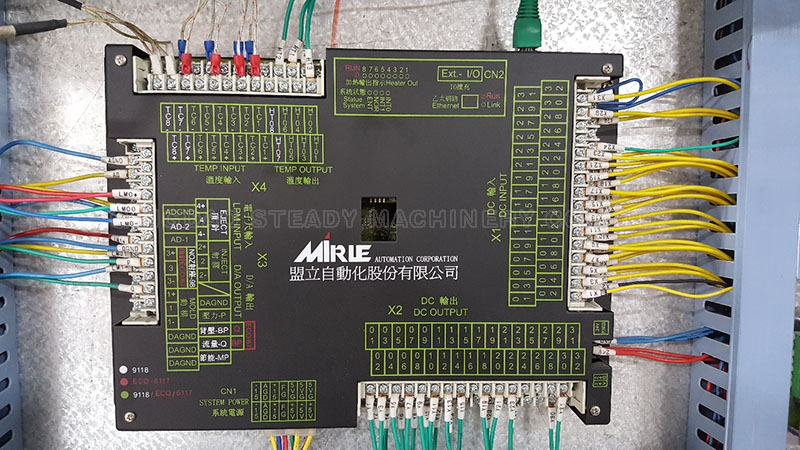

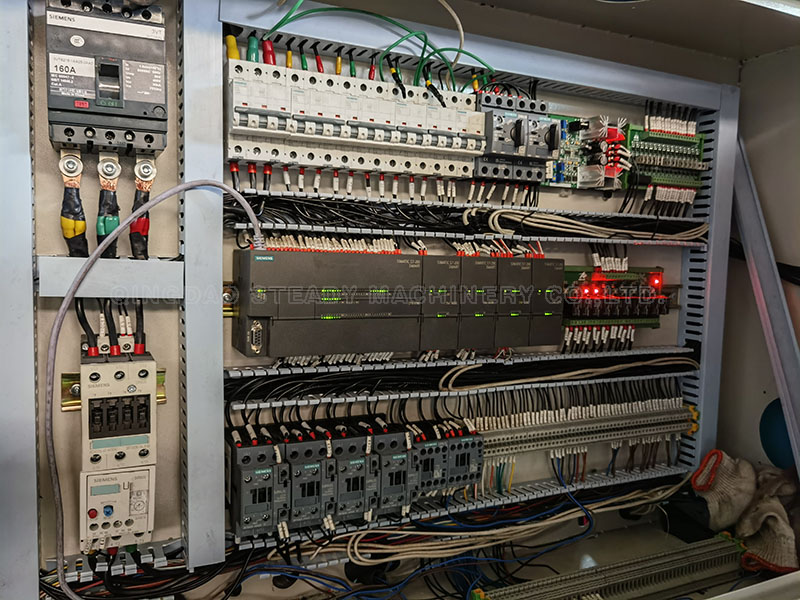

Control Box

Mainly there are two kinds of electronics for choice. 1. Taiwan brand Mirle

2. Siemens brand

Oil Cylinder and Piston of my company's rubber vulcanizing press machine:

Oil cylinder adopts QT500-7 ductile iron, called FCD50 in Japan, and for some huge size machines, we adopt cast steel oil cylinder;

piston adopts chilled hard alloy cast iron; seal adopt imported international quality sealing ring and dustproof ring, to ensure long working life.

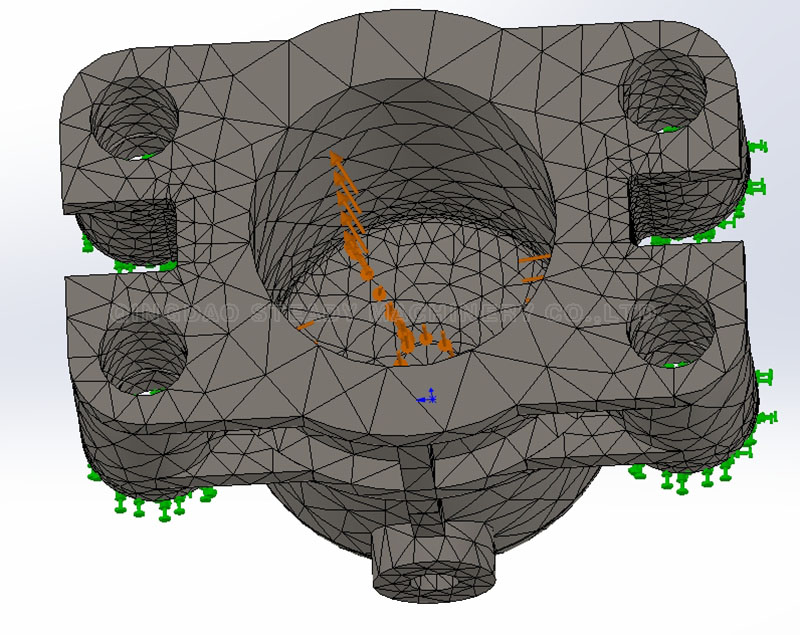

FEA(Finite Elements Analysis) anylysis of parts strength:

Main parts of our rubber vulcanizing press machine, all adopts casted ductile iron or cast steel, which has good stability, don't deformation.

The piston of our rubber vulcanizing press machine adopts cold/chilled hard cast iron

1、Basic knowledge of cold hard cast iron

Cold hard cast iron is a casting alloy material that is based on elements such as iron, carbon, and silicon. By adding alloying elements such as chromium, molybdenum, and vanadium, and through casting and heat treatment processes, it achieves excellent hardness and wear resistance. Its hardness and wear resistance far exceed those of ordinary cast iron and gray iron, and it also has high strength and toughness, which has been widely used in the industrial field.

2、 The Hardness Characteristics of Cold Hardened Cast Iron

The hardness of cold hard cast iron is mainly achieved through heat treatment and chemical composition control. Compared to other casting materials, its hardness is extremely high, usually between 60-65 HRC, while the hardness of steel is only between 50-55 HRC.

3、 The manufacturing process of cold hard cast iron

The manufacturing process of cold hard cast iron mainly includes two processes: casting and heat treatment. During the casting process, control the chemical composition ratio in the as cast state to ensure the ratio of ferrite and pearlite; During the heat treatment process, magnesium spheroidization is subjected to high-temperature treatment, followed by quenching and tempering to obtain excellent hardness and toughness.

4、 The Application Prospects of Cold Hardened Cast Iron

Due to its excellent properties such as hardness and wear resistance, cold cast iron is widely used in manufacturing mechanical parts and tools under high load and high wear working environments. In the field of engineering machinery, some key components have also begun to use cold cast iron materials to improve the service life and safety performance of machinery.

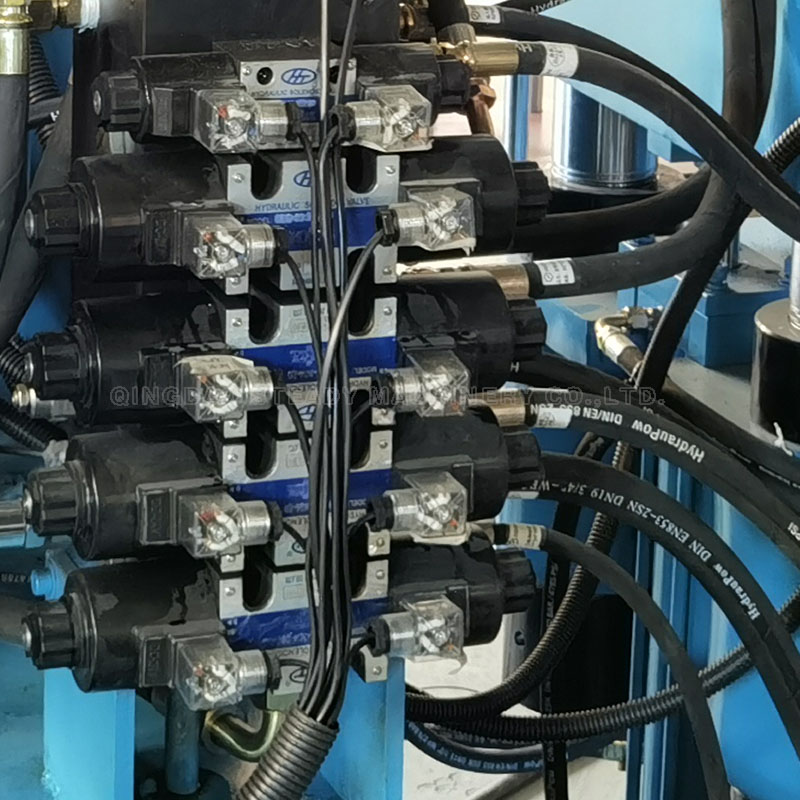

Valves

Qingdao Steady Machinery Co.,Ltd. adopts international famous brand solenoid valves for it's rubber vulcanizing press machine.

Which works accurately and has a long service life.

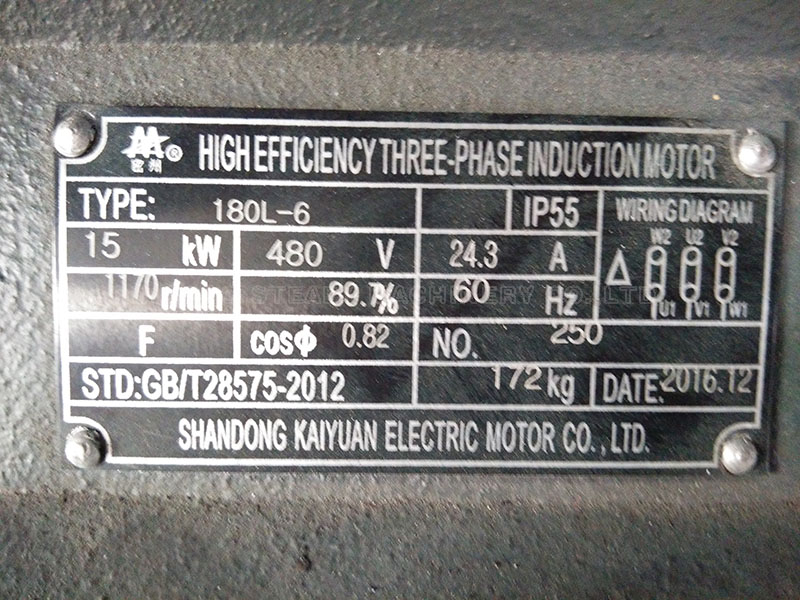

Motor

We adopts China famous brand motor or imported brand motor if customers' have special demand.

The brand of motor we choose uses high-quality copper wire for coils and wiring, which has excellent conductivity.

Copper wire motors have good conductivity, low resistivity, and can achieve larger output power at smaller currents, thereby reducing electrical energy loss. Good corrosion resistance.

Copper wire motors are less prone to rusting and have a longer service life.

Excellent reliability. The connection points and joints of copper wire motors are easy to solder and connect, thus having higher reliability.

More durable.

The durability of copper wire motors is better than that of aluminum wire motors, because aluminum wire has a higher resistance than copper wire and generates higher heat during use, which can easily burn out the motor.

More energy-efficient, copper wire motors have a smaller resistance and lower heat generation, making them more energy-efficient.

More silent, copper wire motors used in our rubber vulcanizing press machine have less noise because aluminum wire motors have a noise level approximately 7 decibels higher than copper wire motors.

Good parts ensures good machine quality, but it need plus a good design.

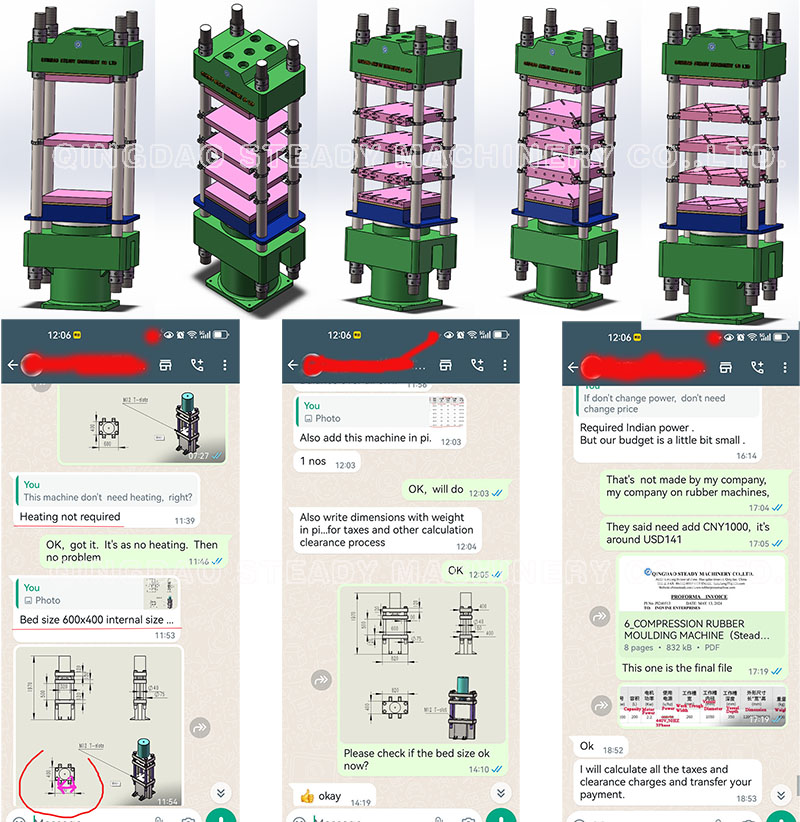

Our engineer service team provide in time design according to customers work needs or special requirements:

Various kinds rubber products can be made by rubber vulcanizing press machine

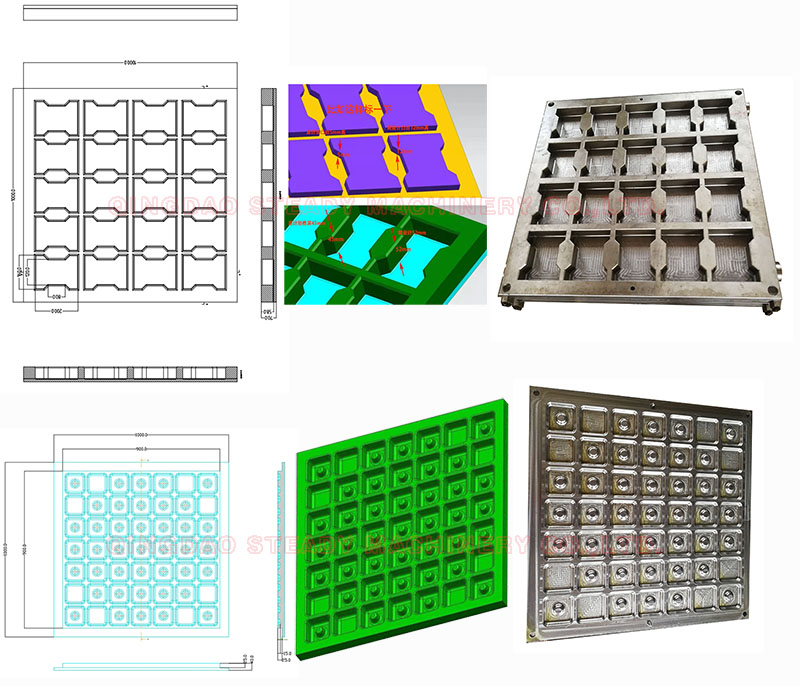

Rubber Molds

We can also make molds according to clients' samples or drawings:

Just contact us

Comments: