The combination conveyor belt hot vulcanization docking joint machine is a specialized equipment for vulcanizing conveyor belt joints. It can reliably connect the two ends of the conveyor belt through the hot vulcanization

process to ensure joint strength and overall continuity and stability of the conveyor belt. The design of such machines typically includes the following key features and components:

1. * * Combination design * *: means that the machine can be flexibly combined and installed according to the width and joint length of the conveyor belt, adapting to the vulcanization needs of different specifications of

conveyor belt joints, and facilitating on-site operation and transportation.

2. Electric heating: Using electric heating elements to uniformly heat the joint area of the conveyor belt, ensuring that the vulcanized rubber material can be fully melted and effectively bonded, forming a high-strength

vulcanized joint. This heating method is fast and controllable, which helps to improve the quality of vulcanization.

3. * * Pressure System * *: Provides uniform pressure (such as 0-2MPa) to ensure that the joint can tightly adhere during the vulcanization process, eliminate bubbles, and enhance the physical properties and durability of the joint.

4. Lightweight materials: Many models use lightweight aluminum alloy materials to make the main structure, which not only reduces the weight of the equipment, facilitates handling and installation, but also ensures

the durability and good thermal conductivity of the equipment.

5. * * Easy to operate * *: Equipped with a simple or fully automatic electronic control box, the operation process is simpler and faster, even non professionals can easily operate after training.

6. Widely used: Widely used in industries such as mining, metallurgy, cement, electricity, ports, and logistics, it is particularly important for vulcanizing long-distance and high-strength conveyor belt joints.

Common Models, if you need other models or have other special technical requirements on size, pressure, working layer number, please just contact us.

Model | Belt Width | SplicingDimension(mm) | HeatingPlate Size(mm) | Power(kw) | Overall Dimension(cm) | Weight(kg) |

ST-650 | 650 | 650x830 | 810x830 | 10 | 140x83x63 | 440 |

650x1000 | 810x1000 | 12 | 140x100x63 | 530 | ||

ST-800 | 800 | 800x830 | 960x830 | 12 | 150x83x63 | 515 |

800x1000 | 960x1000 | 14 | 150x100x63 | 630 | ||

ST-1000 | 1000 | 1000x830 | 1160x830 | 15 | 170x83x63 | 600 |

1000x1000 | 1160x1000 | 17 | 180x100x63 | 715 | ||

ST-1200 | 1200 | 1200x830 | 1360x830 | 17 | 192x83x75 | 800 |

1200x1000 | 1360x1000 | 20 | 198x100x75 | 912 | ||

ST-1400 | 1400 | 1400x830 | 1560x830 | 20 | 215x83x75 | 885 |

1400x1000 | 1560x1000 | 23 | 220x100x75 | 1050 | ||

ST-1600 | 1600 | 1600x830 | 1760x830 | 22 | 240x83x80 | 1130 |

1600x1000 | 1760x1000 | 26 | 245x100x80 | 1325 | ||

ST-1800 | 1800 | 1800x830 | 1960x830 | 25 | 260x83x90 | 1420 |

1800x1000 | 1960x1000 | 29 | 265x100x90 | 1630 | ||

ST-2000 | 2000 | 2000x830 | 2160x830 | 27 | 280x83x90 | 1560 |

2000x1000 | 2160x1000 | 32 | 285x100x90 | 1824 | ||

ST-2200 | 2200 | 2200x830 | 2360x830 | 30 | 300x83x98 | 1720 |

2200x1000 | 2360x1000 | 35 | 305x100x98 | 2030 |

Detail Images of Conveyor Belt Splicing Joint Machine:

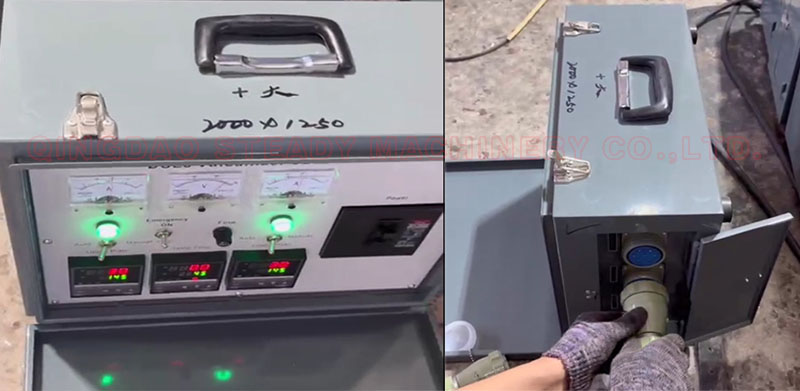

Control Box

CHNT Brand electronics are adoted, works accurate and stable.

* * Intelligent Control * *: Modern conveyor belt joint machines are usually equipped with precision digital automatic control boxes, which can achieve automation of temperature and pressure control, easy operation, and high reliability. The connection between the electrical control box and the host adopts integrated plugins and multi-core cables, which are easy to install and maintain.

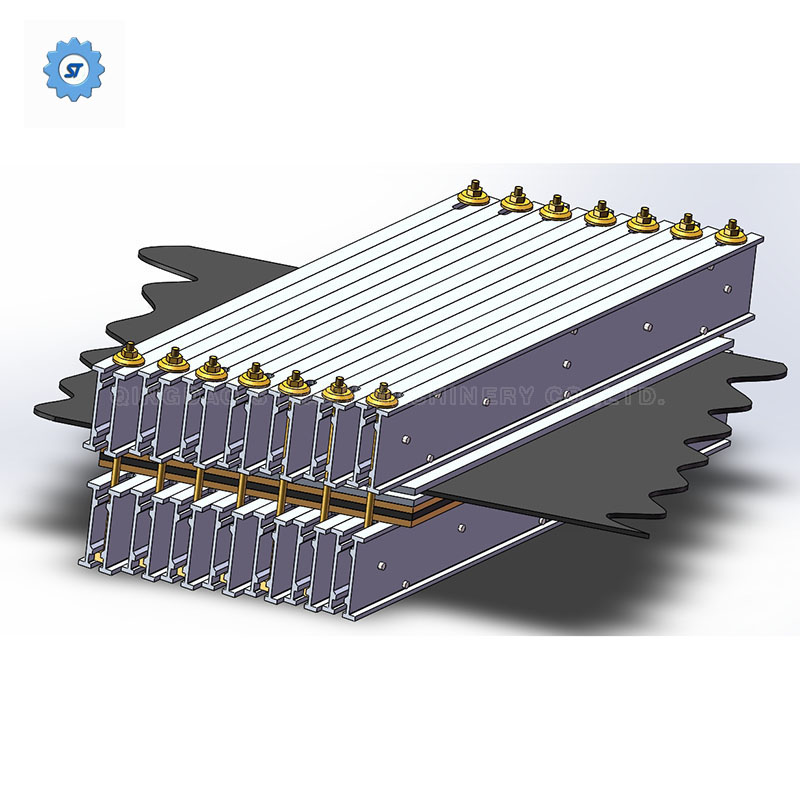

Heating Platen, the heating platen can be designed with or without the fast water cooling tunnel.

* * Temperature Control * *: Used in conjunction with aluminum alloy heating plates, the thermal couple(also called temperature sensor) one end inserted into the heating platen, another end connect with the control box, through the plug and socket, they connect each other to test, transfer and control the temperature. These heating plates are also made of high-purity and high thermal conductivity aluminum alloy materials, which can quickly and evenly heat, ensuring that the rubber in the joint area can be fully vulcanized, enhancing the firmness and durability of the joint.

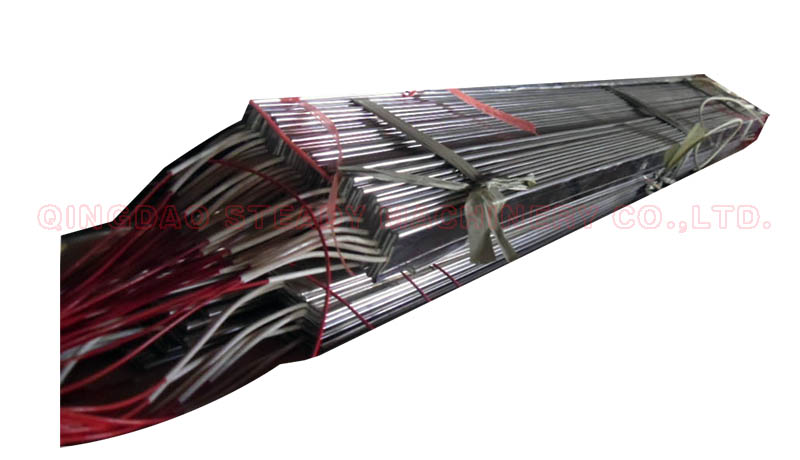

Heating Element

High quality heating sheet/strip is adopted in our rubber conveyor belt joint machine, which ensures trouble free and long service life. And it's easy to replacement.

Pressure adding rubber water pressure bag/chamber :

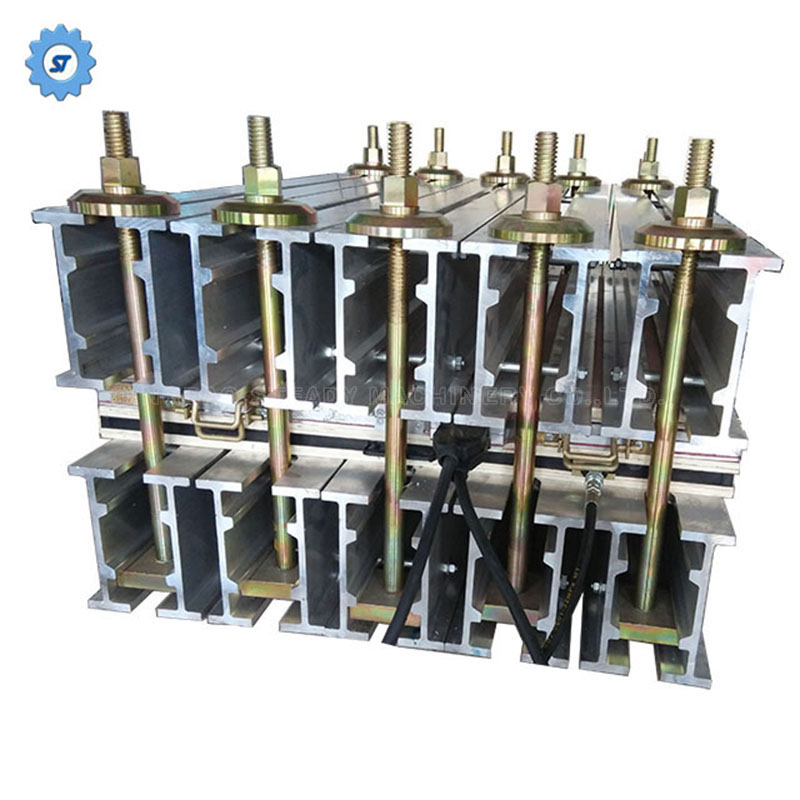

The aluminum alloy frame water pressure plate of the conveyor belt joint machine is a key component in the vulcanization equipment, mainly used to provide uniform and strong pressure during the vulcanization process of the conveyor belt joint, to ensure that the joint parts can be firmly bonded together. Below is a brief introduction to some of the main features and functions of this component:

1. * * Material * *: The frame is usually made of high-strength and highly plastic aluminum alloy materials. This material is not only lightweight, but also has good mechanical properties and thermal conductivity, which helps the overall lightweight and efficient operation of the machine.

2. * * Water pressure plate design * *: As a pressure application component, the water pressure plate applies uniform pressure to the conveyor belt joint through internal water injection and pressurization. It has the characteristics of large expansion amplitude, uniform pressure distribution, and strong pressure bearing capacity, which can ensure that every part of the joint area can receive the same and sufficient pressure during the vulcanization process, thereby forming high-quality joints.

3. * * Pressure Supply System * *: The pressure of the water pressure plate is usually supplied by an electric pump or a manual pump, which can be flexibly adjusted and maintain a stable water pressure, usually up to 1.0-3.0 MPa, to meet the vulcanization needs of conveyor belts with different thicknesses and strengths.

High quality water pump, easy to use, and not easy have problem

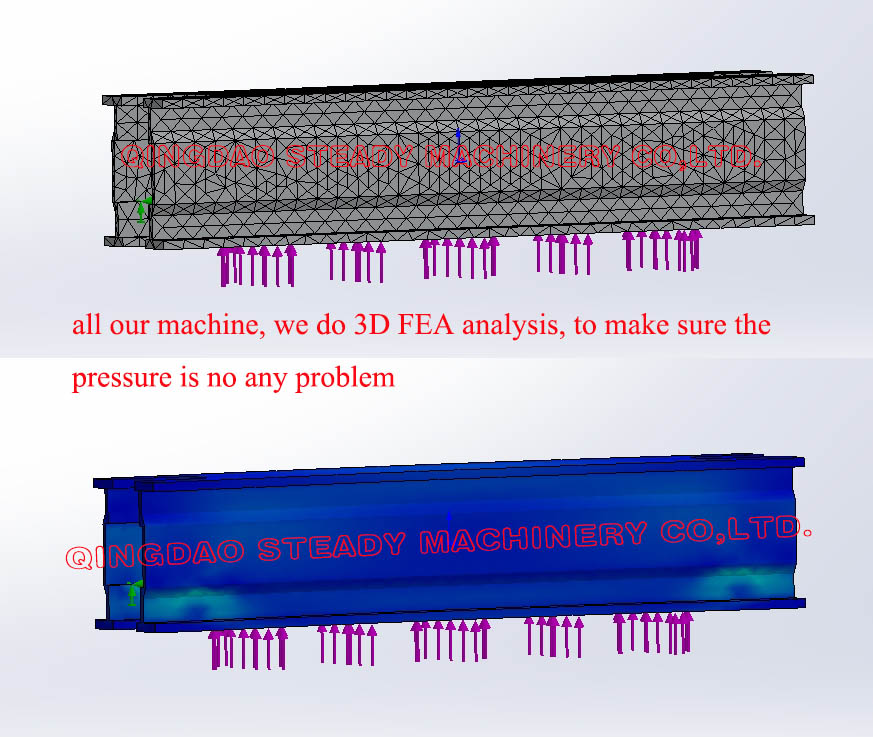

3D design and FEA( Finite Elements Analysis) , plus our 20+ really production experience in the field, ensure our machine is high precision and enough strength to meet work needs, long service life and trouble free.

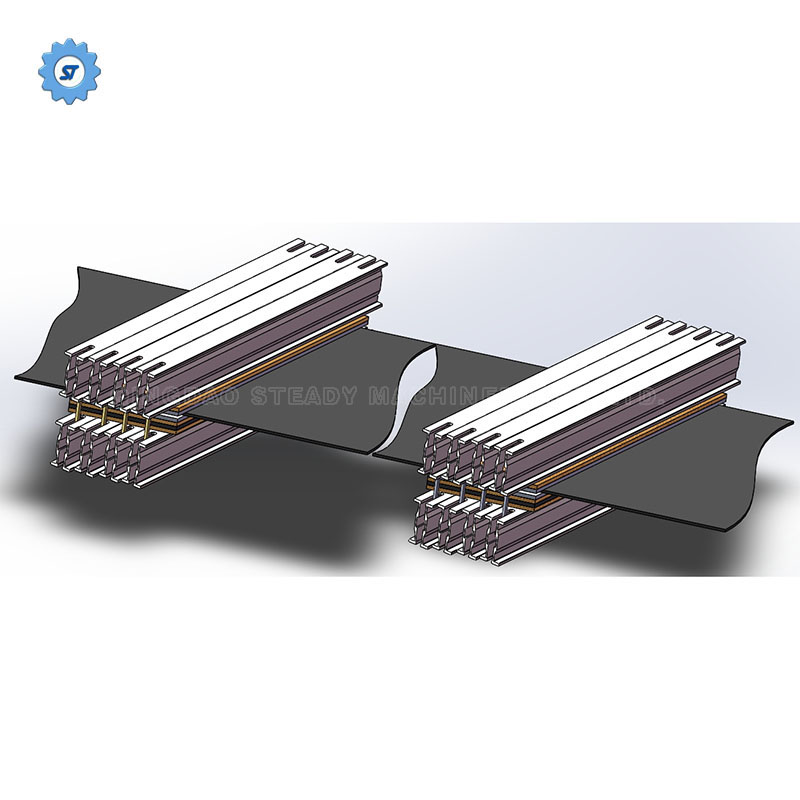

Below machine, can used as two sets seperate small machine, and when put close together, they can be use as a big set rubber conveyor belt splicing joint machine.

The use of the machine is very easy, just plug the the male plug into socket, switch on the power, then you can use the machine.

Rubber Belt Splicing Joint Machines Working in Various Spots

Just contact us

Comments: