Wood vacuum drying equipment, also known as vacuum kilns or vacuum wood dryers, is specialized equipment used for the drying of wood in a controlled environment.

It is commonly used in the woodworking industry to reduce the moisture content of wood, resulting in improved stability, reduced drying time, and minimized defects.

Here are the key features and components of wood vacuum drying equipment:

1. Vacuum Chamber: The vacuum chamber is a sealed enclosure where the wood is placed for the drying process. It is typically made of sturdy materials such as stainless steel and is designed to

withstand the pressure differentials created during the vacuum and drying cycles.

2. Vacuum Pump: The equipment is equipped with a vacuum pump that creates a negative pressure inside the chamber. This causes moisture within the wood to evaporate at lower temperatures compared to

traditional drying methods, reducing the risk of wood degradation and improving drying efficiency.

3. Heating System: Wood vacuum drying equipment often includes a heating system to provide heat energy to the wood during the drying process. The heating system can use electric heaters,

hot water, or hot oil circulation to raise the temperature inside the chamber.

4. Moisture Control System: The equipment may have a moisture control system that monitors and controls the humidity levels within the chamber during the drying process. This helps to ensure precise and consistent

drying conditions, leading to improved drying quality.

5. Monitoring and Control System: Wood vacuum drying equipment usually includes a monitoring and control system that allows operators to set and monitor various drying parameters such as temperature, vacuum level,

and drying time. This system provides real-time feedback and allows for precise control over the drying process.

6. Safety Features: Wood vacuum drying equipment incorporates safety features to protect operators and prevent accidents. These features can include pressure sensors, emergency stop buttons, and safety interlocks to

ensure safe operation during the drying process.

Wood vacuum drying equipment offers several advantages over traditional wood drying methods. It allows for faster drying times, reduced energy consumption, improved wood quality, and better preservation of the wood's

natural color and properties. Vacuum drying also minimizes the risk of wood defects such as warping, cracking, and checking, resulting in high-quality dried wood for various woodworking applications.

The wood tank equipment machine has multipurposes--wood vacuum drying, wood carbonization, flame retardant, wood dying, wood, anti-corrosion, wood optimization etc,

So just tell us your work needs, we can make you a most appropriate proposal with most reasonable price.

Main manufacturing basis TSG 21-2016 HB5342.2012 | TSG21-2016 HB5342.2012 AMS2750、BAC5621、QCACPS、CPS、D6-49327、D6-56273 |

Technical Production Standard | GB/T150-2011《pressure vessel》 |

Welding Technical Standards | NB/T47015-2011 |

Pressure Plate Standard | GB/T713-2014;NB/T47008-2017;GB/T8163-2018 |

Welding Inspection Standard | NB/T47013.2-2015 |

Water Pressure Test Standard | pure water quality; No leakage, no abnormal sound or vibration |

Appearance Treatment Standard | cylinder appearance, internal metal polishing, polishing treatment, spraying high-temperature resistant coating and rust proof primer |

And our tank with thermal keeping layer, which saves energy consumption.

The Advantage is safety, reliable, energy saving, compact structure.

Below is model file for your reference, if you need other models or sizes, just feel free to ask us.

Item | Parameters | |

Size | Volume | 3、6、9、12CBM |

Pressure | Max. Working Pressure | 0.45mpa |

Pressurizing Rate | 0-0.06mpa/min,continuous adjustable | |

Lowering Pressure Rate | 0-0.06mpa/min,continuous adjustable | |

Pressure Control Precision | ±0.002mpa | |

Temperature | Max. Working Temperature | 185℃ |

Temperature Rising Rate(Zero Load) | 1-5℃/min,continuous adjustable | |

Temperature lowering rate(Zero Load) | 1-5℃/min, continuous adjustable | |

Temperature control precision | ±1.5℃ | |

Temperature Evenness | ±2.0℃ | |

Temperature measure spot | 2 spot | |

Vacuum | Max. Vacuum Degree | -0.098mpa |

Vacuum Tank | 0.1³,-0.098mpa | |

Thermo Keeping Method | Tank body double layer thermo keeping | |

Thermo keeping effect | Long time working(5 hours+), furnace body around Max. Temperature 42℃ | |

Tank Body Life | ≥10 years(10000 times+) | |

Exhaust Noise | ≤80dB | |

Door Open Method | Quick open type | |

Tank Body Material | Q345R | |

Heating Method | Electrical | |

Control Method | Siemens PLC Auto Control | |

Safety Method | Tank door double safety interlock device, tank body triple safety interlock device | |

Sealing Method | Air filled fluorine rubber sealing | |

High Temperature Wind Blower | Ensures air circulation and temperature even | |

Power | 380v±5,50HZ, 3phas 5 wire, or as per require | |

Detail Images:

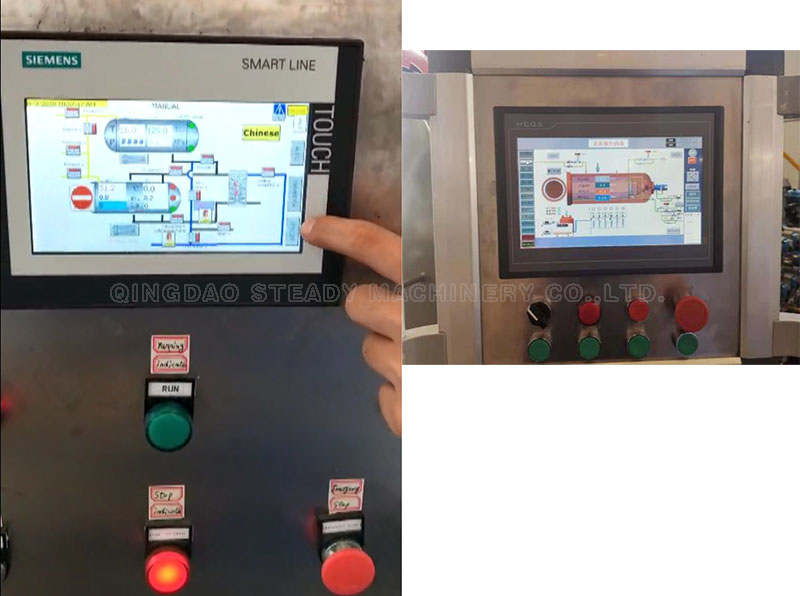

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put one for a reference.

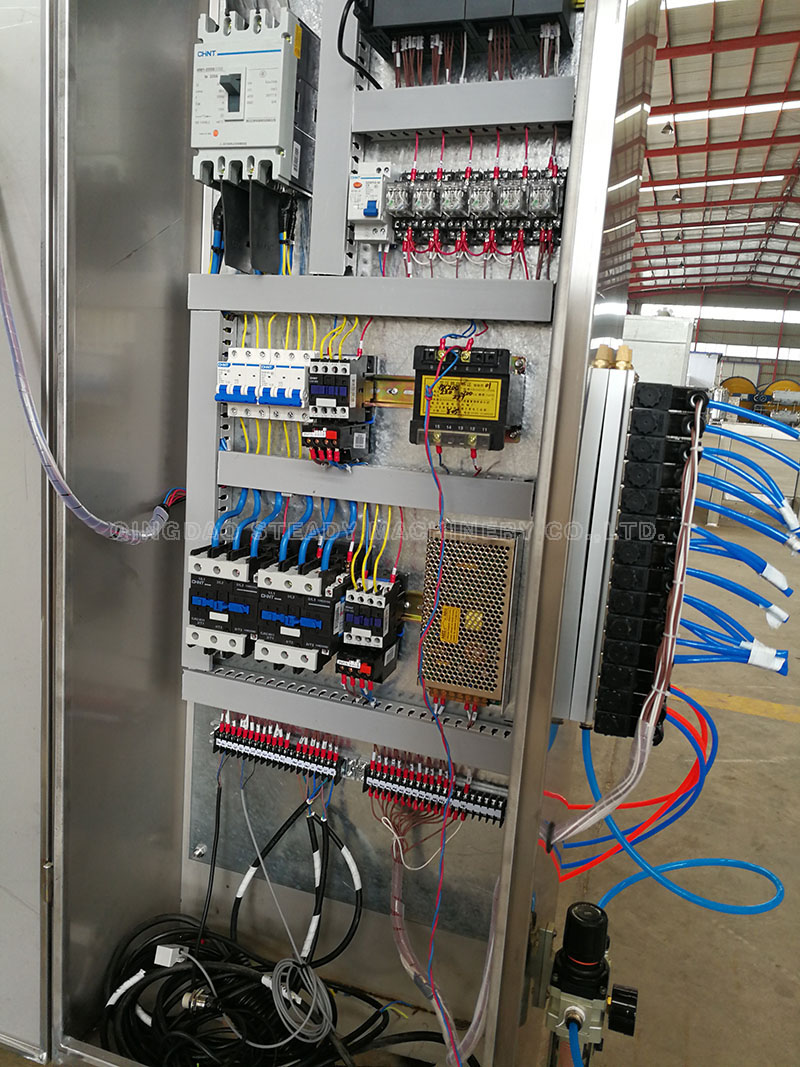

Control Box

CHNT brand, it's best brand of China made, works accurate and stable. When customers have different power voltage supply, we put a transformer into the control box, as you can see it from below picture.

Tank body, we use Q345R as raw material

Steel Q345-R, as a widely used low alloy high-strength structural steel, represents the yield strength with "Q" in its grade, while "345" indicates that the yield strength (in megapascals, MPa) of this steel under

standard test conditions reaches 345MPa. The subsequent "R" symbol specifically indicates that the steel is suitable for container manufacturing,

that is, it has good welding performance and certain high-temperature resistance characteristics, and is suitable for the production of pressure vessels, storage tanks and other equipment.

The characteristics of Q345-R steel include:

1. Mechanical properties: In addition to having a yield strength of no less than 345MPa, it also has good tensile strength, generally up to 470-630MPa, as well as good toughness, plasticity, and weldability, ensuring

the safety of components under complex stress states.

2. Chemical composition: As a low alloy steel, Q345-R contains small amounts of alloying elements such as manganese (Mn), silicon (Si), titanium (Ti), niobium (Nb), etc. The addition of these elements can significantly

improve the comprehensive mechanical properties of the steel without significantly increasing its weight, ensuring strength while reducing the structural weight.

3. Corrosion resistance and high temperature resistance: Although Q345 series steel is mainly designed for room temperature environments, Q345-R has certain corrosion resistance and resistance to medium and

low temperatures (usually from room temperature to about 400 ℃) through specific composition adjustments and heat treatment, making it suitable for manufacturing containers that can withstand certain temperature and pressure.

4. Processing performance: Good cold forming and welding performance make Q345-R easy to process into various complex shaped components, meeting different engineering needs, especially in the fields of chemical, petroleum,

energy, etc. It has a wide range of applications.

In practical applications, Q345-R steel needs to undergo strict quality control and testing to ensure that its various performance indicators comply with relevant national standards (such as GB/T 713), in order to ensure its safety

and reliability under design and usage conditions. Whether it's building large oil storage tanks, high-pressure vessels, or industrial boilers, Q345-R is a trusted choice for engineers.

Ends cover of the tank body, aslo Q345R steel:

autoclave tank loading container export

work in user's factory

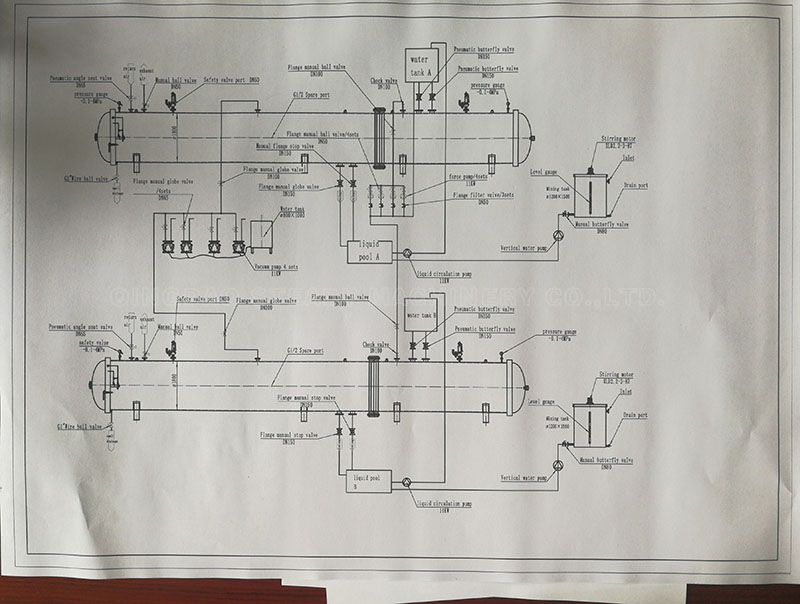

Hot press tank machine, a drawing for reference

The wood tank equipment machine has multipurposes--wood vacuum drying, wood carbonization, flame retardant, wood dying, wood, anti-corrosion, wood optimization etc,

So just tell us your work needs, we can make you a most appropriate proposal with most reasonable price.

Just contact us

Comments: