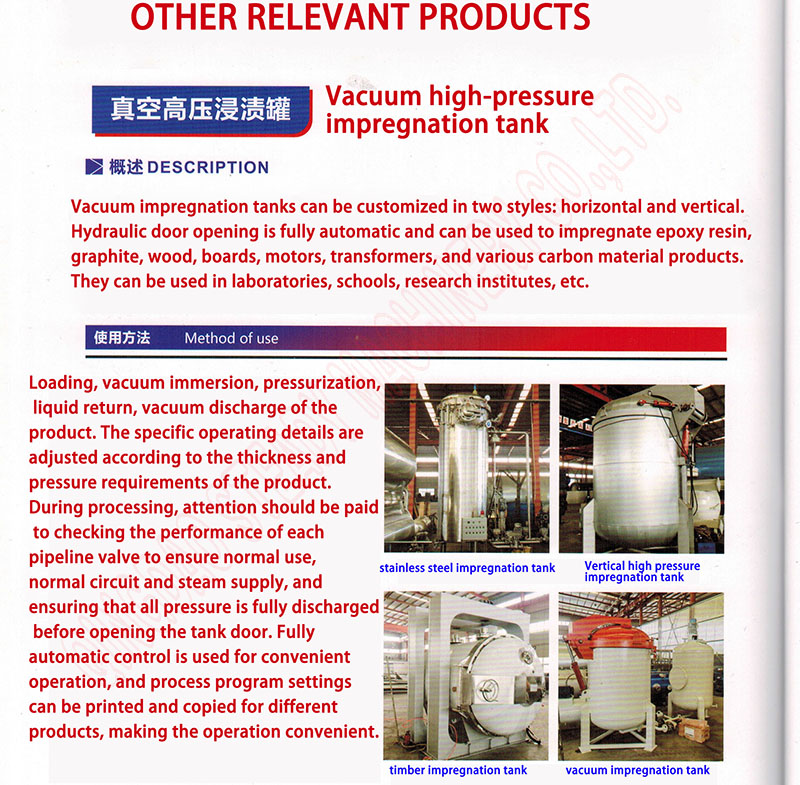

The vacuum high pressure impregnation tank can be used to treat many kinds of materials, like to impregnate epoxy resin, graphite, wood, wood plate, motor enameled wire, transformer, and all kinds of carbon material products etc.

The vacuum high pressure impregnatioon tank can be used in laboratories, schools, research institutes, etc.

Now take wood treatment as example to explain it's work procesure:

Vacuum high-pressure impregnation tank is a device used for processing wood or other porous materials, mainly used to improve the performance of materials, such as enhancing their anti-corrosion,

fire resistance, or improving their mechanical properties. Its working principle and application areas are as follows:

###Working principle

1. Vacuum stage: First, place the wood to be treated into the impregnation tank and close the tank door. Create a low-pressure environment by extracting air from the tank through a vacuum pump.

This process helps to extract air and water from the wood cell cavity, making the wood more porous and facilitating the infiltration of subsequent treatment solutions.

2. * * Pressure impregnation stage * *: After reaching the predetermined vacuum degree, pre prepared chemical treatment liquids (such as preservatives, flame retardants, or resins) are injected into the tank through pipelines.

As the treatment solution is injected, the pressure inside the tank gradually increases, forcing the treatment solution to penetrate deep into the cellular structure of the wood. A high-pressure environment can ensure

that the treatment solution penetrates evenly and deeply into the interior of the wood, achieving the goal of improving its performance.

3. * * Exhaust balance stage * *: After the treatment liquid has fully penetrated, the pressure inside the tank is gradually reduced to allow the excess treatment liquid to flow back to the storage tank, while allowing the excess gas

in the wood to be discharged until the internal and external pressures are balanced.

4. * * Drying stage * *: For certain processes, the treated wood may need to be dried to solidify the treatment solution or remove excess liquid, which may be done in impregnation tanks or transferred to specialized drying equipment.

###Application field

-Wood processing industry: widely used to improve the durability and anti-corrosion ability of outdoor wood structures (such as fences, decks, bridge components).

-Furniture manufacturing: Enhance the stability and aesthetics of furniture wood, such as deep dyeing or increasing surface hardness.

-* * Paper and fiberboard production * *: Improve the fire and waterproof performance of paper or fiberboard.

-* * Research experiment * *: In materials science research, used to test the effects of different solutions on the properties of porous materials.

Vacuum high-pressure impregnation technology is an efficient and environmentally friendly material modification method, which can significantly improve the comprehensive performance of materials and extend their service life,

especially in the field of wood protection and modification.

Main manufacturing basis TSG 21-2016 HB5342.2012 | TSG21-2016 HB5342.2012 AMS2750、BAC5621、QCACPS、CPS、D6-49327、D6-56273 |

Technical Production Standard | GB/T150-2011《pressure vessel》 |

Welding Technical Standards | NB/T47015-2011 |

Pressure Plate Standard | GB/T713-2014;NB/T47008-2017;GB/T8163-2018 |

Welding Inspection Standard | NB/T47013.2-2015 |

Water Pressure Test Standard | pure water quality; No leakage, no abnormal sound or vibration |

Appearance Treatment Standard | cylinder appearance, internal metal polishing, polishing treatment, spraying high-temperature resistant coating and rust proof primer |

And our tank with thermal keeping layer, which saves energy consumption.

The Advantage is safety, reliable, energy saving, compact structure.

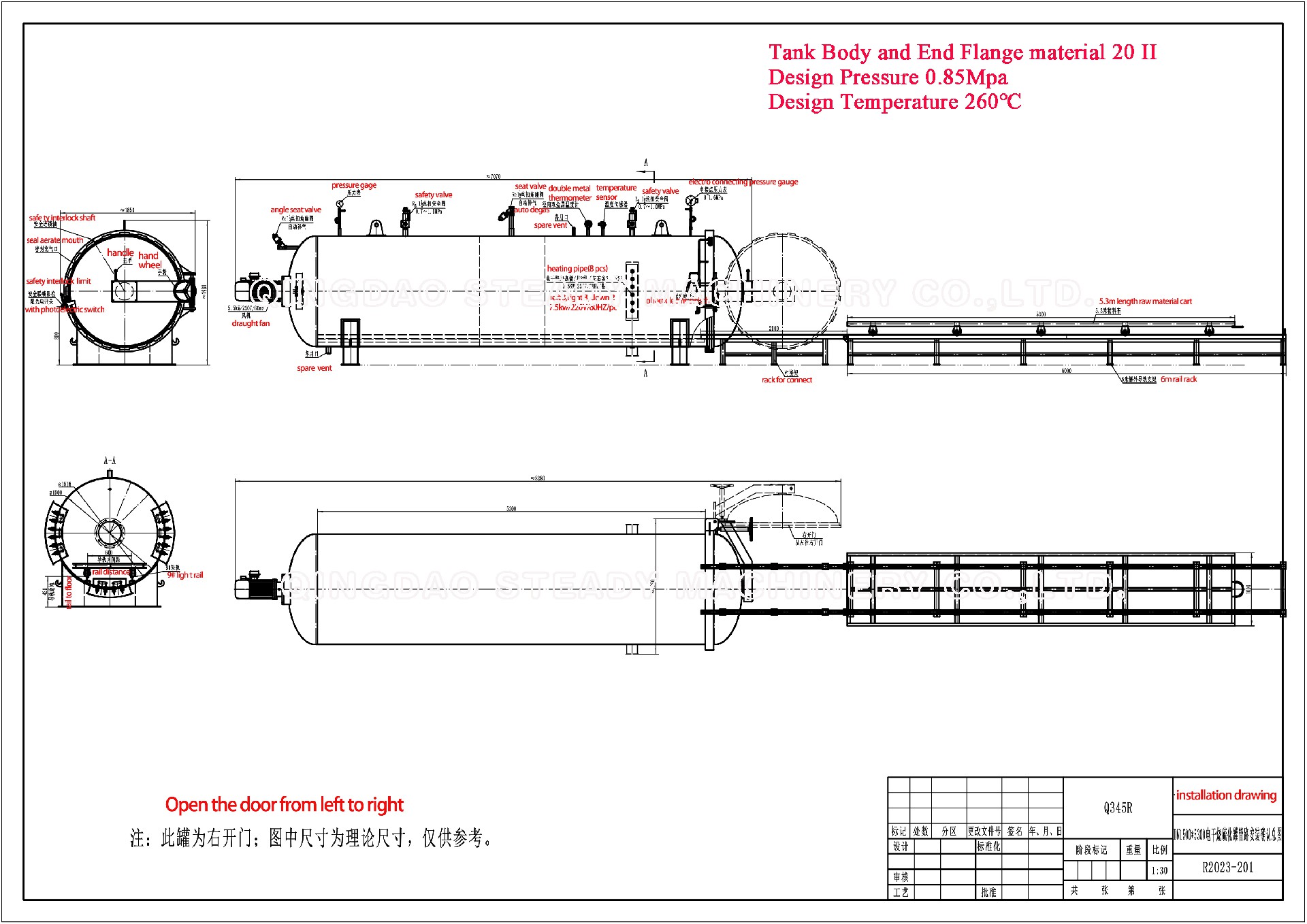

Below is one of the models for your reference, if you need other models or sizes, just feel free to ask us.

1.1main technical parameter | UNIT | Value or notes | |

Size | ㎜ | DN1500x5000 | |

Tank body raw material | - | Q345R | |

Wall thickness | ㎜ | 16 | |

Door flange | - | 16Mn | |

Inner diameter | ㎜ | 1500 | |

Work length | ㎜ | 4000 | |

Design pressure | MPa | 1.25 | |

Max. Work temperature | MPa | ≤0.9 | |

Design temperature | ℃ | 260 | |

Max. Working temperature | ℃ | 250 | |

Design life | Year | ≥15 | |

Door open method | - | Electric hydraulic side door opening; Tank door position sensing, manual and automatic protection safety interlocking, emergency stop function | |

Thermal keeping method | - | Tank insulation (customized high-density aluminum silicate) with 100 mm internal insulation (patented technology) | |

Heat preservation thickness | ㎜ | 50 | |

Heating Method | - | Tail heater Heating power of 300KW, supporting max 4 ℃/min heating under no load | |

Cooling Method | - | Air cooling, water cooling, natural cooling, multi-mode program controlled automatic switching fault self-diagnosis function Support cooling at MAX0.5-4 ℃/min under no load | |

Design usage | Composite material pressure curing molding | ||

Loading Weight | Kg | 1000 | |

Temperature rising rate | ℃/min | 0.1-4 ℃ adjustable according to program settings (no load or pressure) | |

Initial temperature | ℃ | Room temperature or residual heat in the tank | |

Temperature descend rate | ℃/min | 0.1-4 ℃ adjustable according to program settings (no load or pressure) | |

Cooling to temperature | ℃ | 65(default) | |

Temperature evenness | ℃ | ±1℃(without load) | |

Temperature control accuracy | ℃ | ±0.5℃ | |

Temperature test point | - | 6 | |

Application Field | - | ||

Vacuum High Pressure Impregnation Tank:

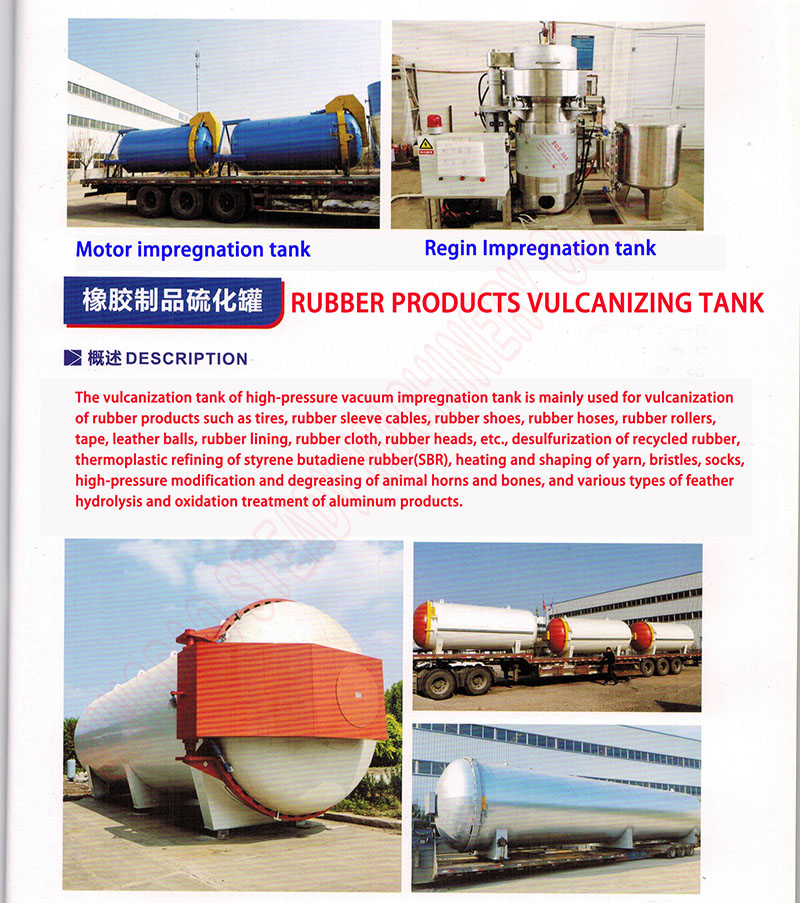

Vacuum high pressure impregnation tank can also be used as vulcanization tank to treat rubber materials, rubber tyre, rubber sleeve cable, rubber shoes, rubber hoses, rubber roller,

rubber belt, rubber ball, rubber lining, rubber cloth and other rubber products.

The vacuum high pressure impregnation tank can also be used for recycled rubber desulfurization, SBR rubber thermoplasticizing;

Yarn, bristles, socks heating setting shape; animal horn and bone high pressure modification, degreasing, all kinds of feather hydrolysis, aluminum products oxidation treatment.

Detail Images:

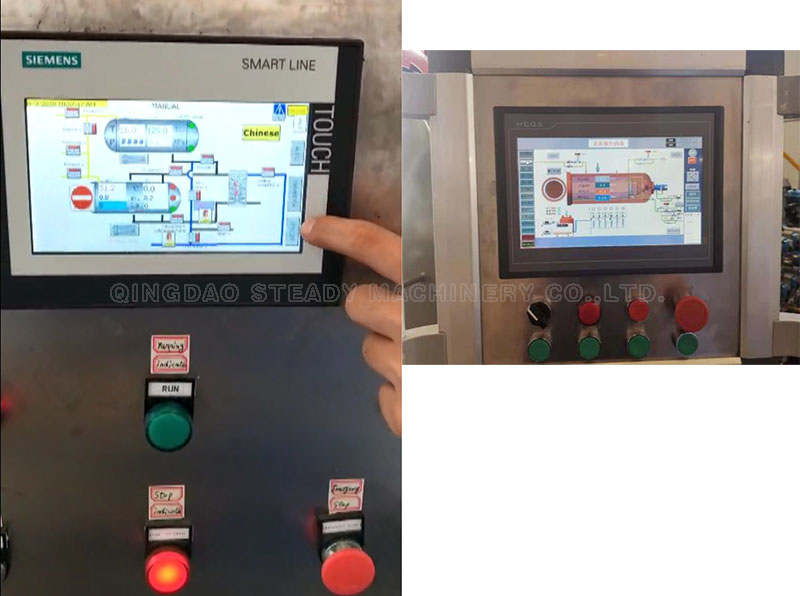

Control Panel

we design different type control panel according to machine needs or customers' requirements, here just put one for a reference.

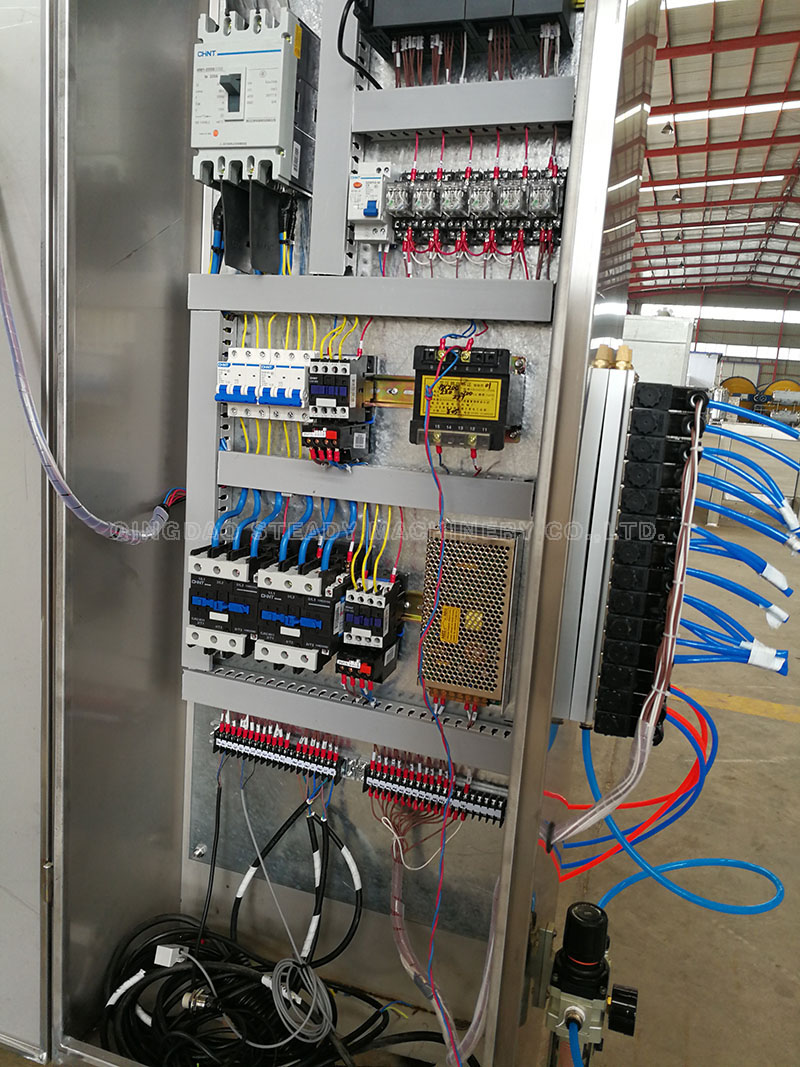

Control Box

CHNT brand, it's best brand of China made, works accurate and stable. When customers have different power voltage supply, we put a transformer into the control box, as you can see it from below picture.

Tank body, we use Q345R as raw material

Steel Q345-R, as a widely used low alloy high-strength structural steel, represents the yield strength with "Q" in its grade, while "345" indicates that the yield strength (in megapascals, MPa) of this steel under

standard test conditions reaches 345MPa. The subsequent "R" symbol specifically indicates that the steel is suitable for container manufacturing,

that is, it has good welding performance and certain high-temperature resistance characteristics, and is suitable for the production of pressure vessels, storage tanks and other equipment.

The characteristics of Q345-R steel include:

1. Mechanical properties: In addition to having a yield strength of no less than 345MPa, it also has good tensile strength, generally up to 470-630MPa, as well as good toughness, plasticity, and weldability, ensuring

the safety of components under complex stress states.

2. Chemical composition: As a low alloy steel, Q345-R contains small amounts of alloying elements such as manganese (Mn), silicon (Si), titanium (Ti), niobium (Nb), etc. The addition of these elements can significantly

improve the comprehensive mechanical properties of the steel without significantly increasing its weight, ensuring strength while reducing the structural weight.

3. Corrosion resistance and high temperature resistance: Although Q345 series steel is mainly designed for room temperature environments, Q345-R has certain corrosion resistance and resistance to medium and

low temperatures (usually from room temperature to about 400 ℃) through specific composition adjustments and heat treatment, making it suitable for manufacturing containers that can withstand certain temperature and pressure.

4. Processing performance: Good cold forming and welding performance make Q345-R easy to process into various complex shaped components, meeting different engineering needs, especially in the fields of chemical, petroleum,

energy, etc. It has a wide range of applications.

In practical applications, Q345-R steel needs to undergo strict quality control and testing to ensure that its various performance indicators comply with relevant national standards (such as GB/T 713), in order to ensure its safety

and reliability under design and usage conditions. Whether it's building large oil storage tanks, high-pressure vessels, or industrial boilers, Q345-R is a trusted choice for engineers.

Ends cover of the tank body, aslo Q345R steel:

autoclave tank loading container export

work in user's factory

Hot press tank machine, a drawing for reference

Just contact us

Comments: